An amphiphilic nanotio 2 Powder catalyst and its preparation method and use method

An amphiphilic and catalyst technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve problems that do not involve photocatalytic reactions and applications, time-consuming, Difficulty in operation and other problems, to achieve the effect of practical operation, avoid falling off and self-degradation, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Using unmodified nano-TiO 2 Treatment of simulated organic wastewater:

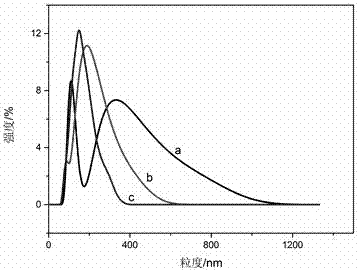

[0035] Take Degussa company P25 nanometer TiO 2 1g, the contact angle is 13°, figure 1 (a) and figure 2 (a) The particle size distribution and Fourier transform infrared spectrum of the powder in water are given respectively. The average particle size of the powder in water is 107.2nm, and the polydispersity index is 1.78. Prepare the suspension according to the mass ratio of powder: water = 1:20, ultrasonically disperse for 35 min, the ultrasonic frequency is 20 Hz, and the power is 950W, and then add organic pollutants into it according to the volume ratio of nitrobenzene: water = 1:20, The blend system was obtained by shearing and emulsifying for 3 minutes in a high-speed disperser with a rotating speed of 18000 r / min.

[0036] The oil-in-water wastewater emulsion was placed under simulated sunlight (300 W visible halogen lamp), reacted for 3 h, and the wastewater degradation rate was 32%. ...

Embodiment 2

[0038] Nano-TiO modified with salicylic acid 2 Treatment of simulated organic wastewater:

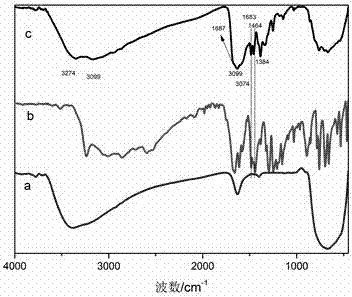

[0039] Dissolve 0.75 g salicylic acid in 30 mL ethanol, and then add 1.5 g Degussa P25 nano TiO 2 Add it to the above mixed solution, and react with ultrasound at 25°C for 10 minutes, ultrasonic frequency 20 Hz, power 950 W, then let it stand for 24 hours, vacuum filter, wash with ethanol 3 times to remove free acid on the surface, freeze-dry for 48 hours , to obtain modified nano-TiO 2 powder, test figure 1 (b) shows that the average particle size of the powder in water is 64nm, and the polydispersity index is 0.875. figure 2 (b) The stretching vibration peaks of the benzene ring appearing in the infrared spectrum (1683 and 1464 cm -1 ) and ester group characteristic peak (1713cm -1 ) confirmed the successful modification.

[0040] Modified TiO 2 Powder, prepare suspension according to the mass ratio of powder: water = 1:20, ultrasonically disperse for 30 min, ultrasonic freque...

Embodiment 3

[0043] Nano TiO modified by the method of the present invention 2 Treatment of simulated organic wastewater:

[0044] Dissolve 0.5 g salicylic acid in 10 mL ethanol, 0.5 g arginine in 5 mL water, then mix the two solutions, and add 2 g Degussa P25 nano TiO 2 Add it into the above mixed solution, and react with ultrasound at 15°C for 10 minutes, ultrasonic frequency 20 Hz, power 950 W, then stand still for 12 hours, vacuum filter, wash with ethanol 3 times to remove free acid on the surface, freeze-dry for 48 hours , to obtain amphiphilic nano-TiO modified by salicylic acid and arginine 2 Powder, the powder contact angle is 75°. figure 1 (c) shows that the average particle size of the powder in water is 36nm, and the polydispersity index is 0.425. figure 2 (c) The stretching vibration peaks of the benzene ring appearing in the infrared spectrum (1683 and 1464 cm -1 ), ester group characteristic peak (1713cm -1 ), -NH 2 Characteristic peaks (3074 and 3099cm -1 ) confirme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com