Construction method of cover-and-cut reverse construction concrete walls and columns with vertical structures

A technology of vertical structure and construction method, which is applied in basic structure engineering, underwater structures, artificial islands, etc., can solve the problems of complicated formwork support, difficult control of concrete quality, and difficult control of the density of post-filling materials, etc. The effect of speeding up construction progress, ensuring construction quality and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

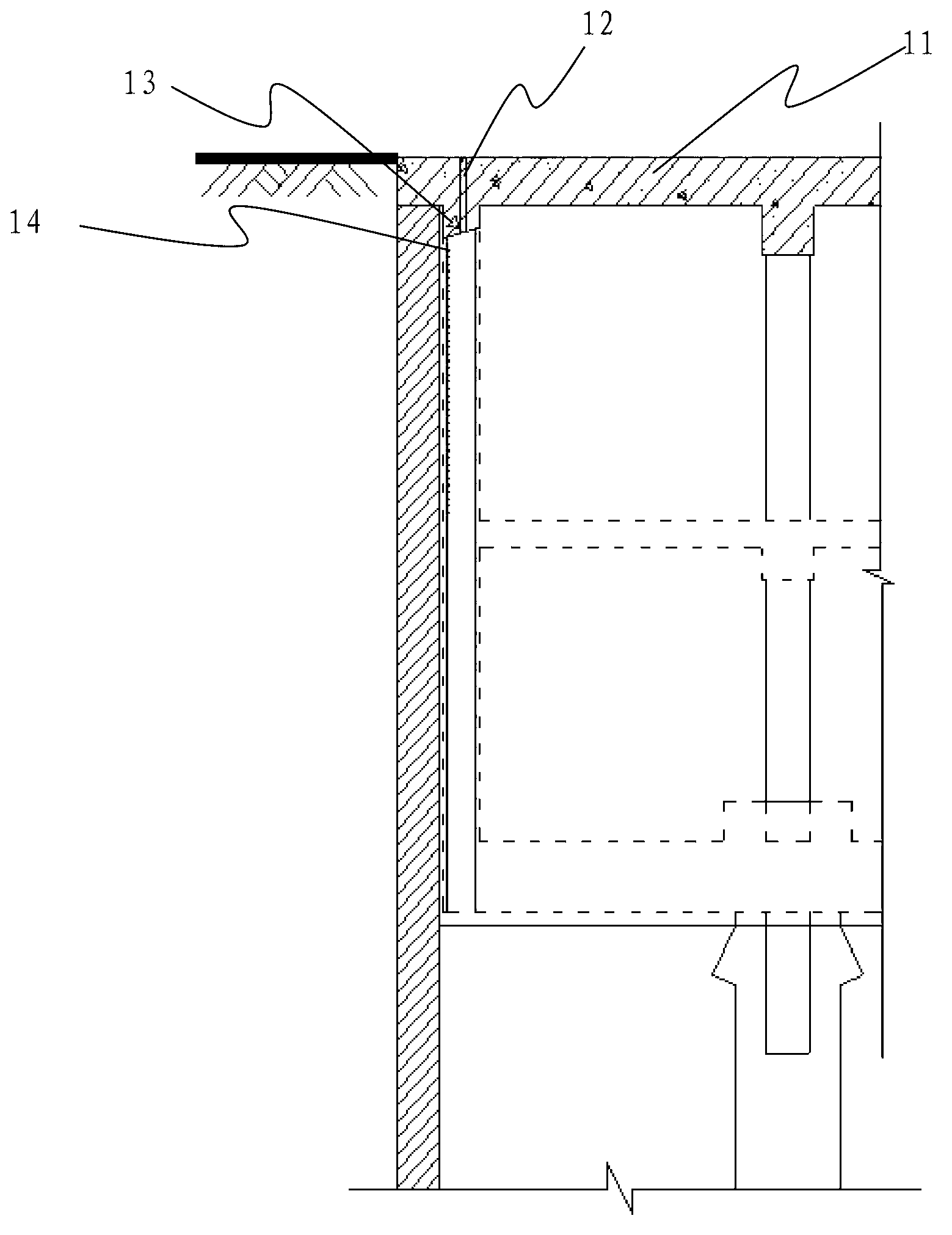

[0018] See first figure 1 According to the design requirements, construct the top floor 11 of the negative layer, and set a lower return section 13 with a height greater than 500mm at the position corresponding to the lower wall and column of the top floor 11. Connecting construction joints, the shoulder-shaped shape can extend the seepage channel of water at the construction joints, and the concrete at the construction joints can be easily filled and compacted by vibration. Reserve 150mm diameter sleeves 12 at intervals of 1000mm in walls and columns for pouring walls and columns concrete, and reserve connection steel bars 14 whose length exceeds 100mm-150mm of the shoulder-shaped lower return section downwards in walls and columns. It is convenient for the connection of the protection and the reinforcement of the lower layer during the excavation of the lower layer of earthwork.

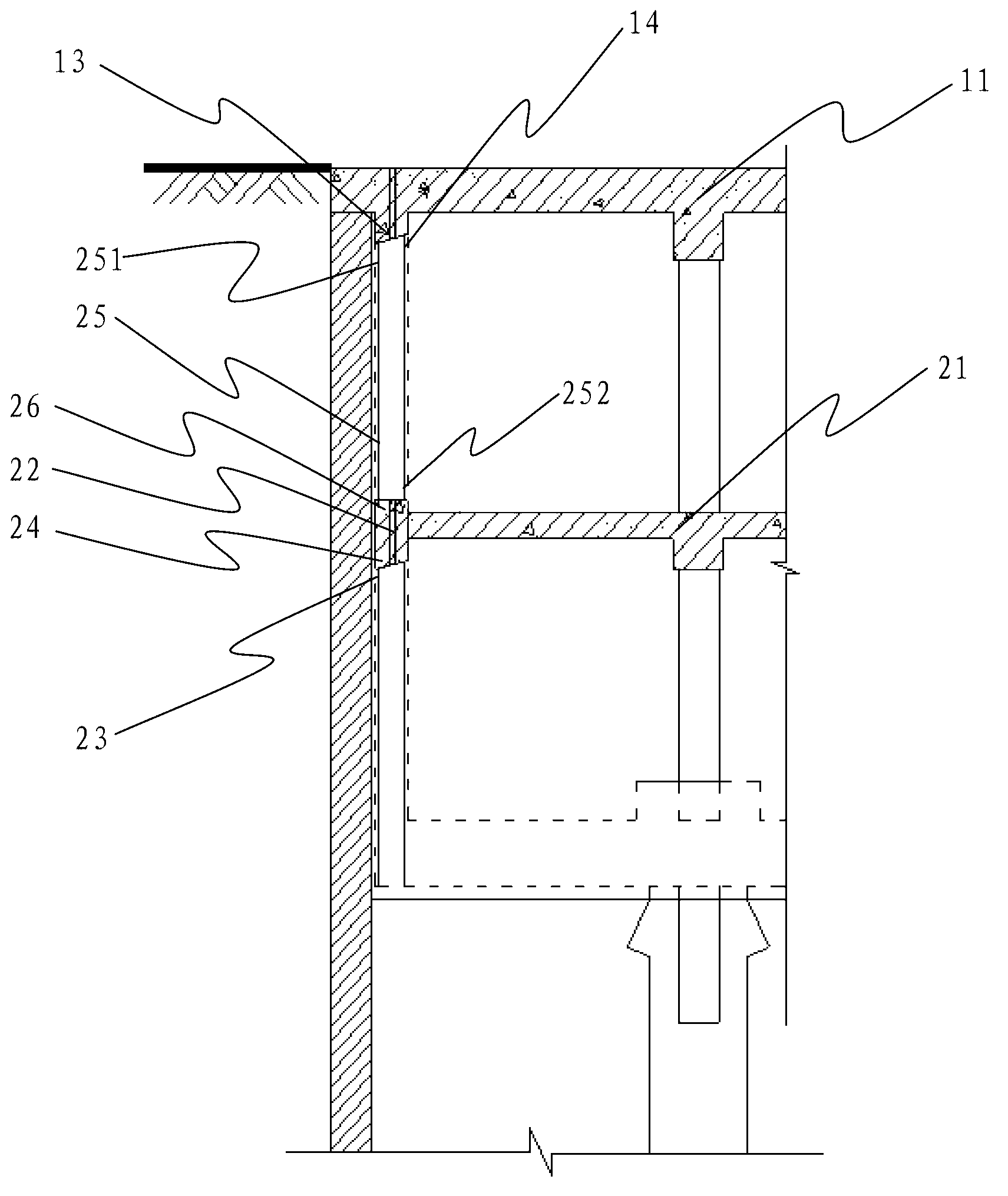

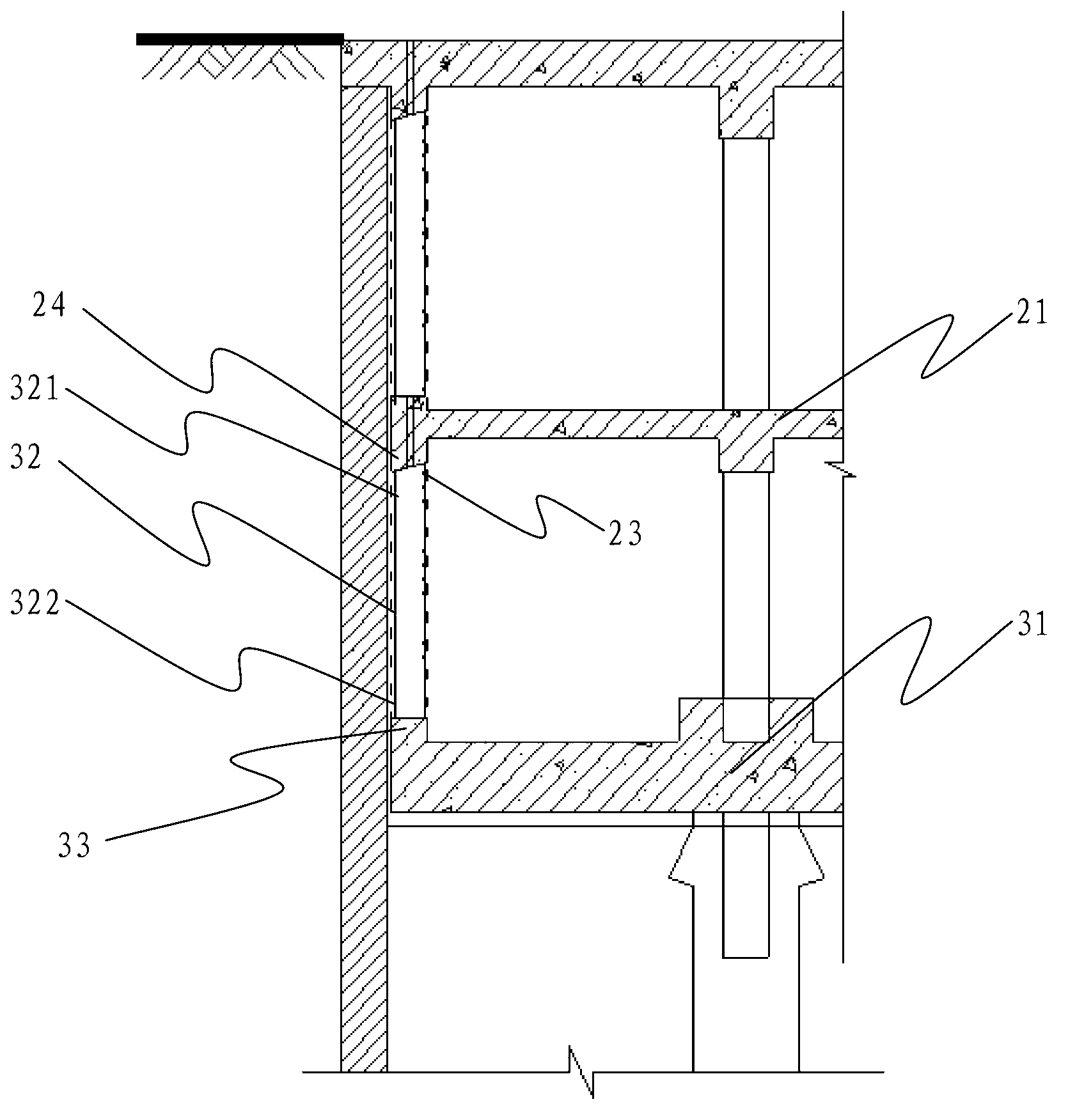

[0019] refer to figure 2 After the structural concrete of the top slab 11 of the negative fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com