Hydraulic self-elevating template for vertical shaft and construction method thereof

A formwork and vertical shaft technology, applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., to achieve the effect of ensuring construction quality, high construction efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

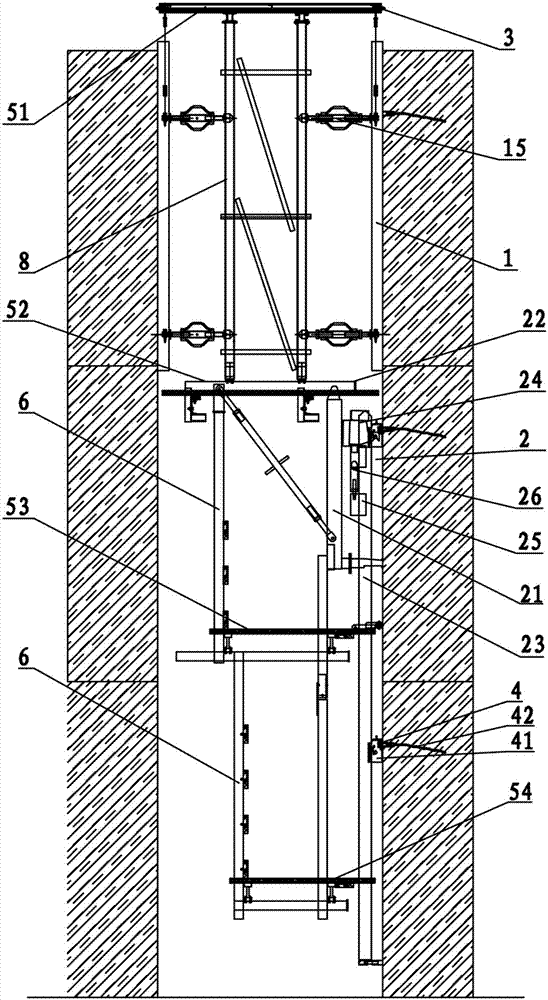

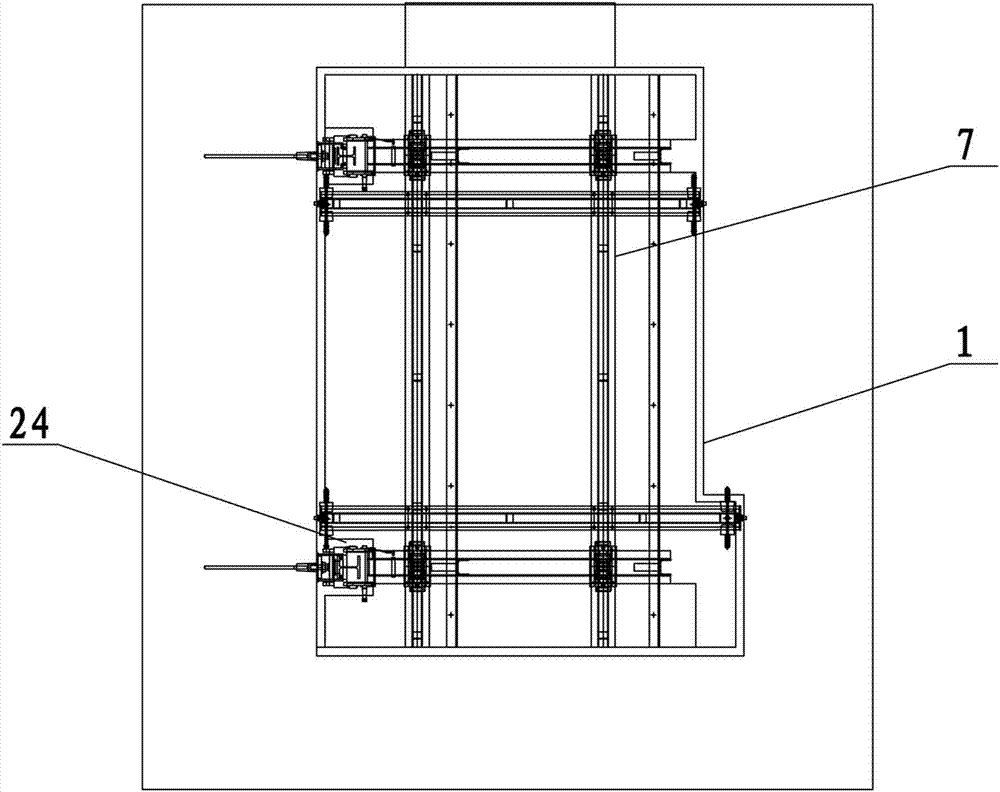

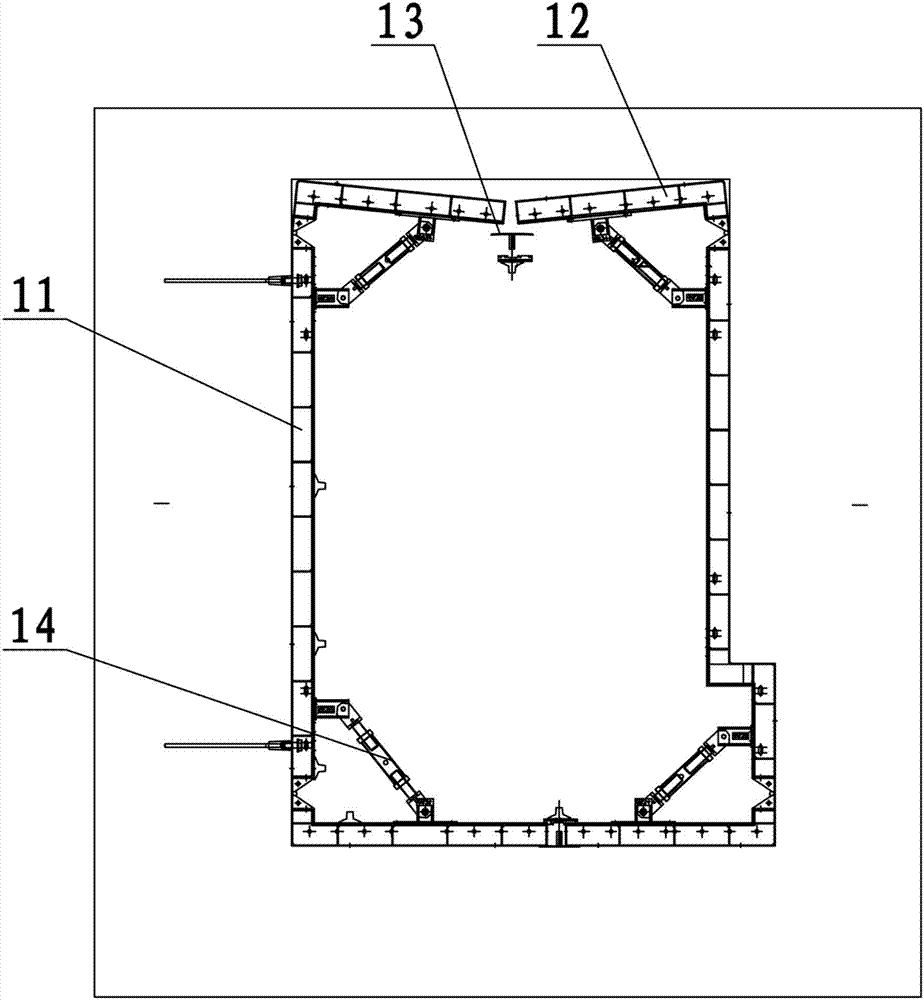

[0044] Such as figure 1 , image 3 Among them, a vertical shaft hydraulic self-elevating formwork, including a formwork device 1 for pouring the inner wall of the vertical shaft;

[0045] In the described formwork device 1, the plane formwork 11 is connected with the pole frame 8 through the formwork adjustment device 15. In this example, the formwork adjustment device 15 adopts a double-ended screw method, which can easily adjust the distance between the formwork and the pole frame 8. distance;

[0046] The two ends of the plane formwork 11 are connected to the corner formwork 12 through the diagonal support 14, and the two ends of the corner formwork 12 and the plane formwork 11 are hinged, and the two ends of the diagonal support 14 are respectively connected to the plane formwork 11 and the corner formwork 12, thereby by adjusting the The double-ended screw rod in the corner support 14 can make the corner formwork 12 rotate around the hinge point, so as to facilitate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com