In-place sensing device for workpiece inside furnace

A technology of induction device and workpiece, applied in furnace components, furnaces, lighting and heating equipment, etc., can solve the problems of production efficiency impact and high failure rate, achieve good protection, reduce impact force, and prevent frequent failure rates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

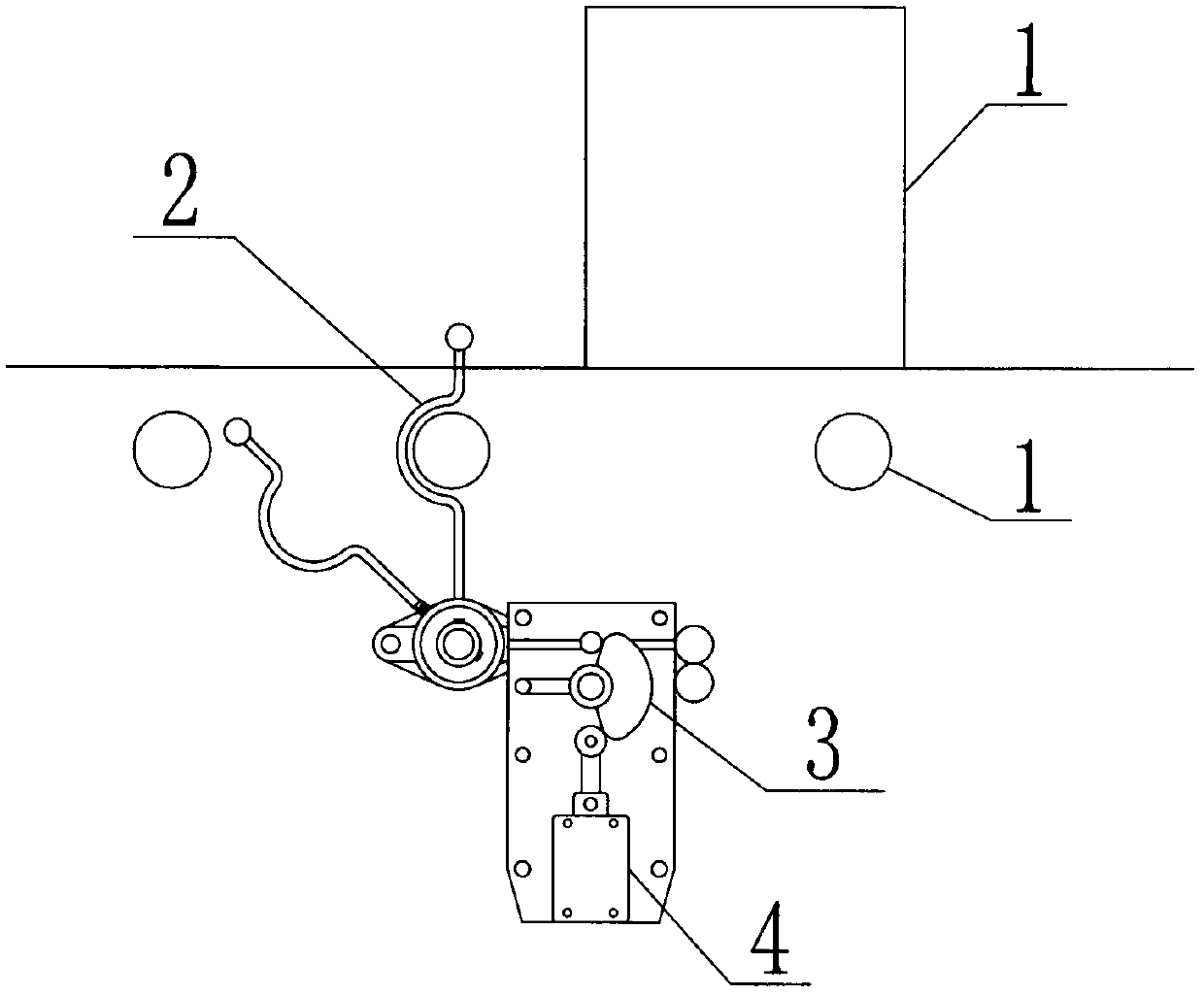

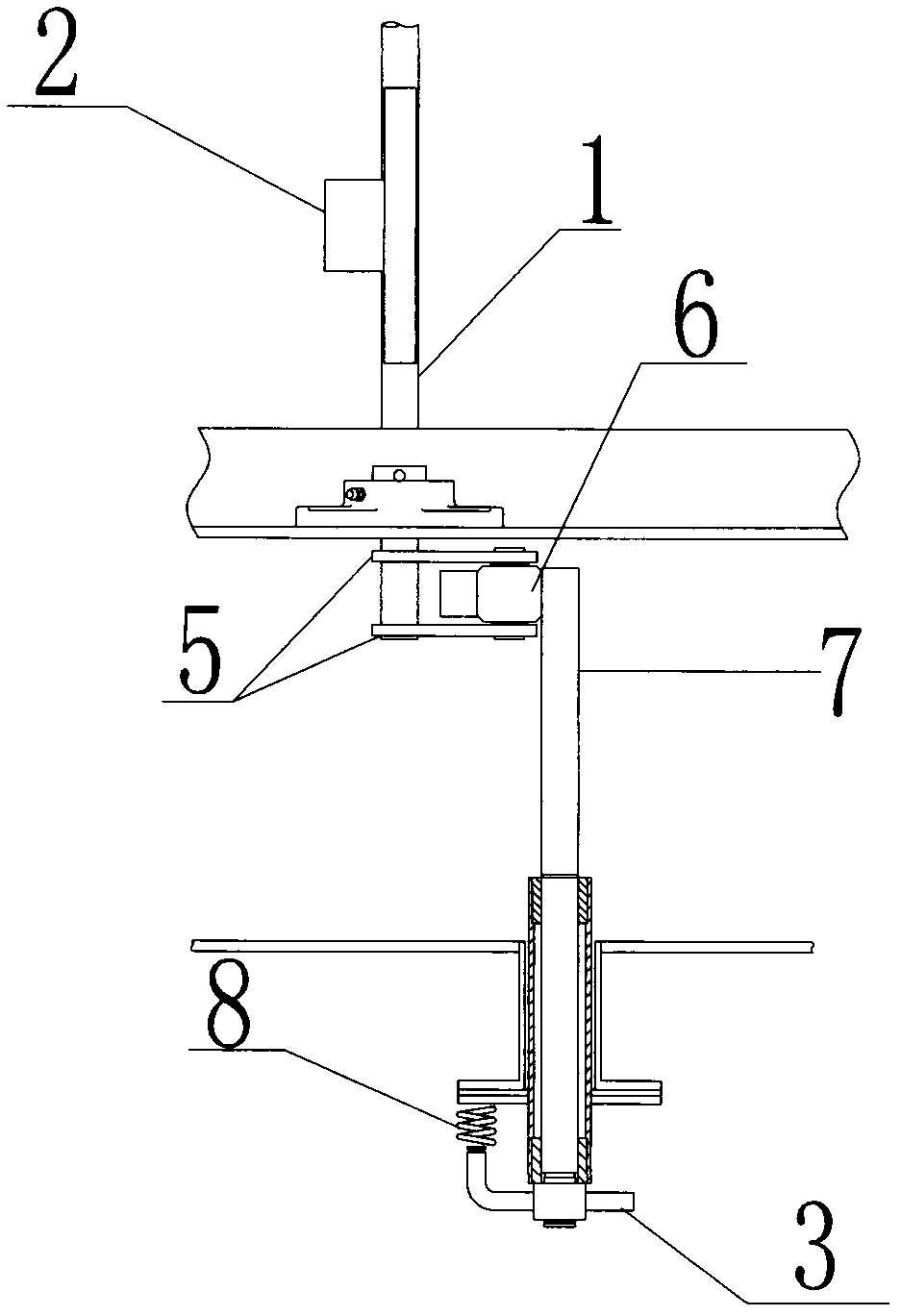

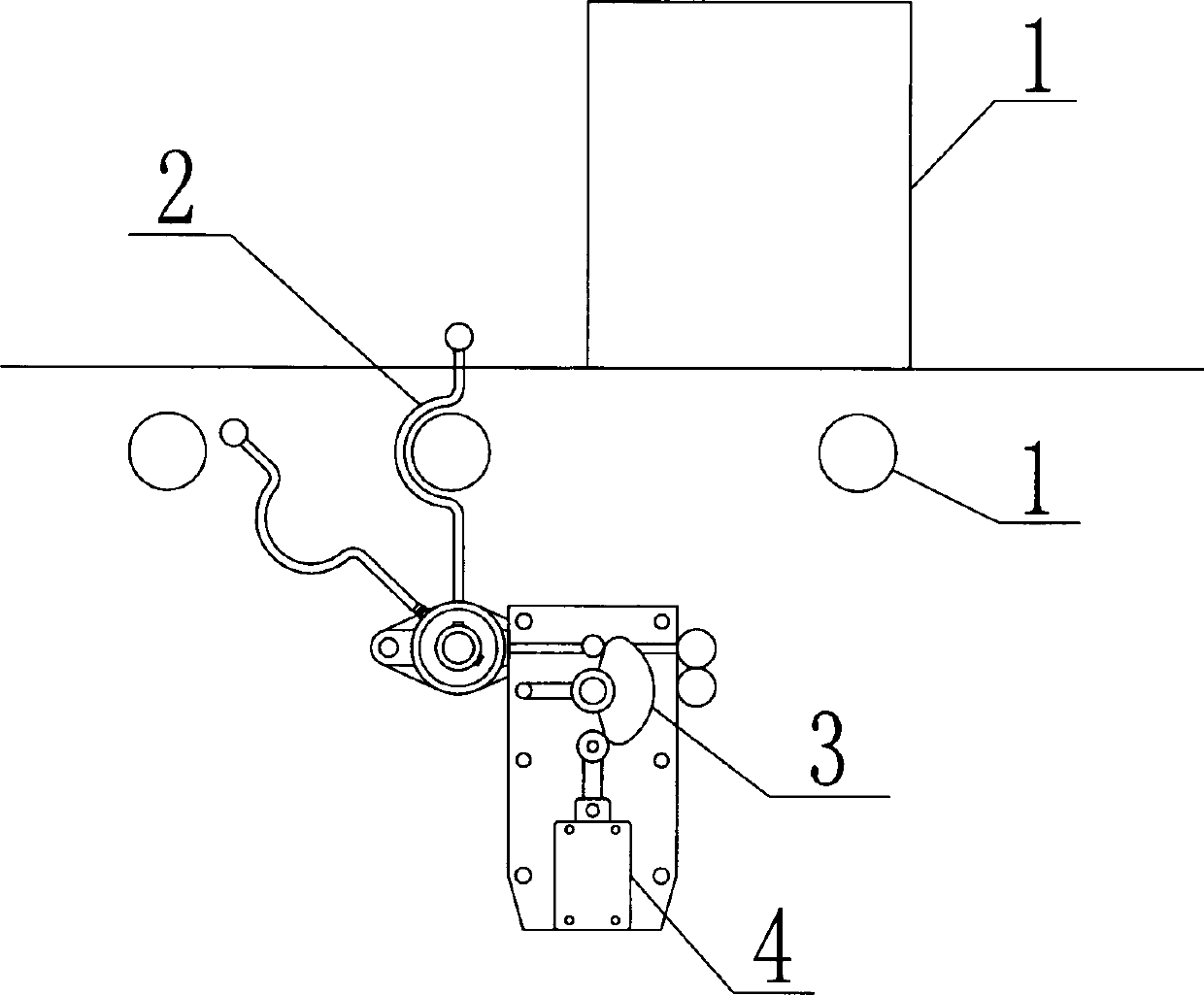

[0013] figure 1 , figure 2 The workpiece in-position sensing device in the furnace is shown, which includes a detection stick 1 connected to the inside and outside of the furnace body. The detection stick 1 in the furnace body is provided with a groove-type detection plate 2, and the end of the detection rod 1 outside the furnace is provided with a fixed plate. 5. A travel switch 4 is arranged on the side of the fixed plate 5; there are two fixed plates 5 on the end of the detection rod 1 outside the furnace, and a roller 6 is arranged between the two fixed plates 5; the roller 6 It is rollingly connected with one end of the detection shaft 7 arranged on its side, and the other end of the detection shaft 7 is provided with a cam type limit plate 3 capable of hitting the travel switch 4; the rear part of the cam type limit plate 3 is provided with a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com