Experiment device for simulating damage failure of conducting roller by work conditions

A technology for simulating material damage and working conditions, applied to measuring devices, analytical materials, instruments, etc., to achieve the effects of low manufacturing and operating costs, simple operation, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

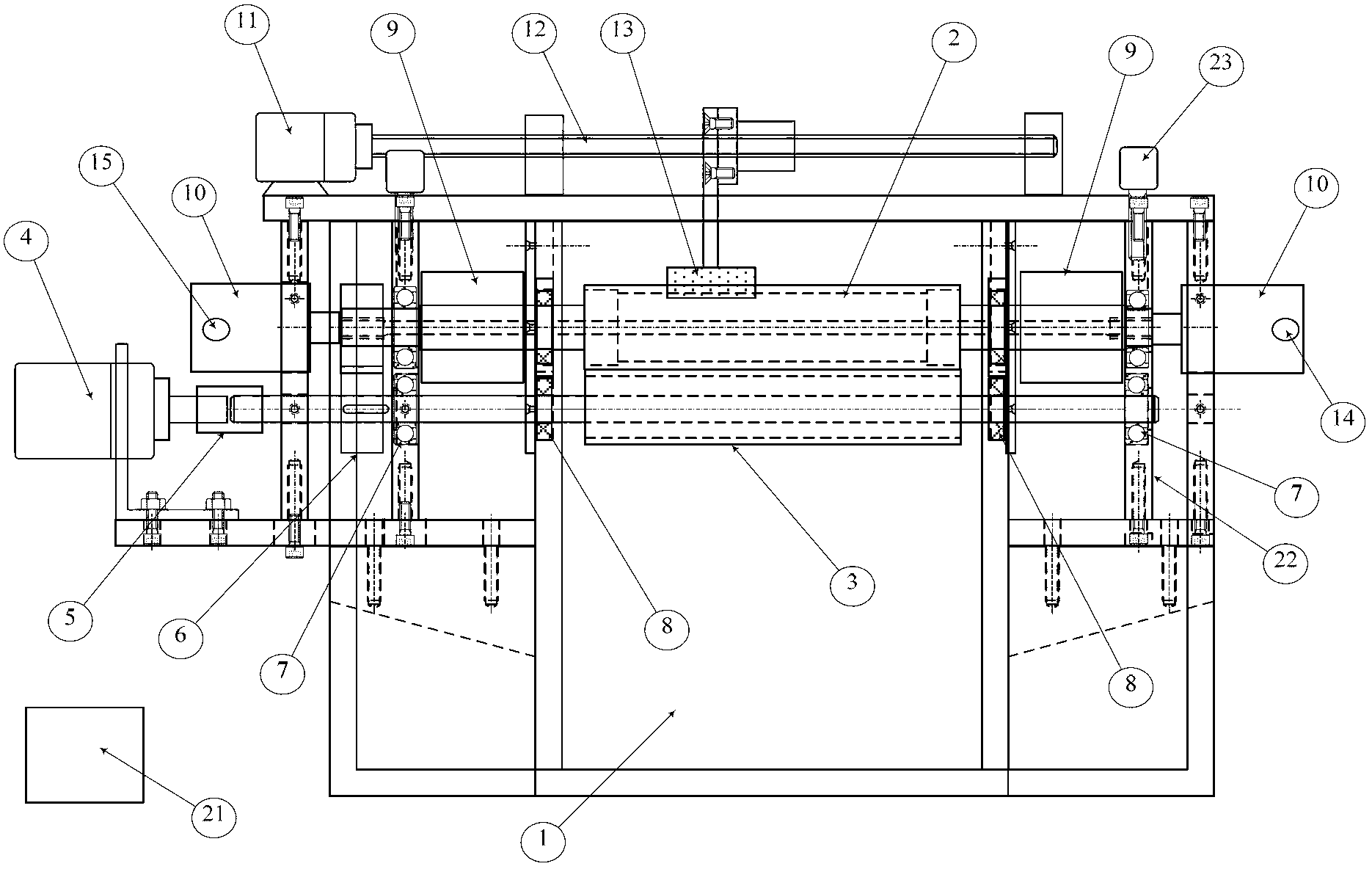

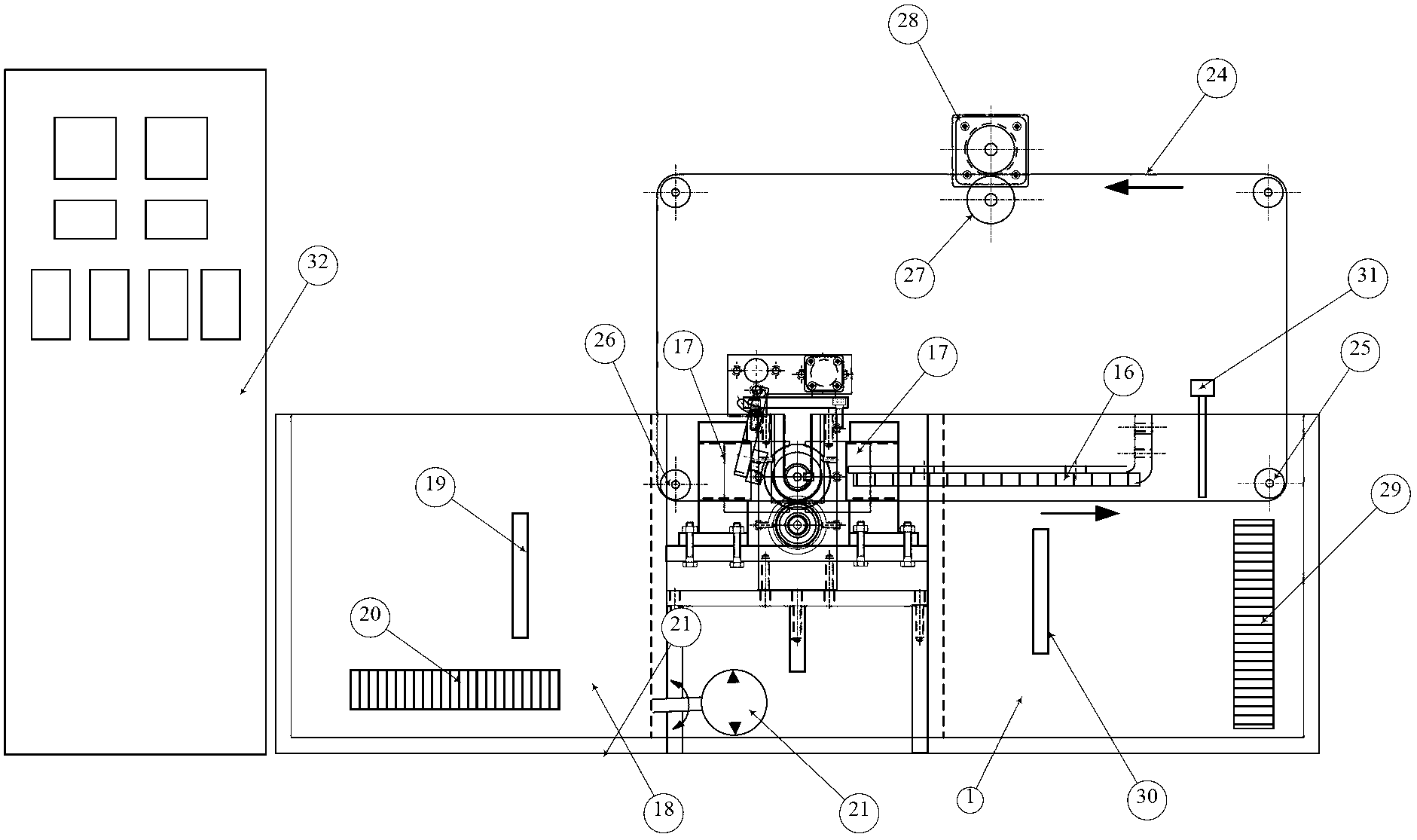

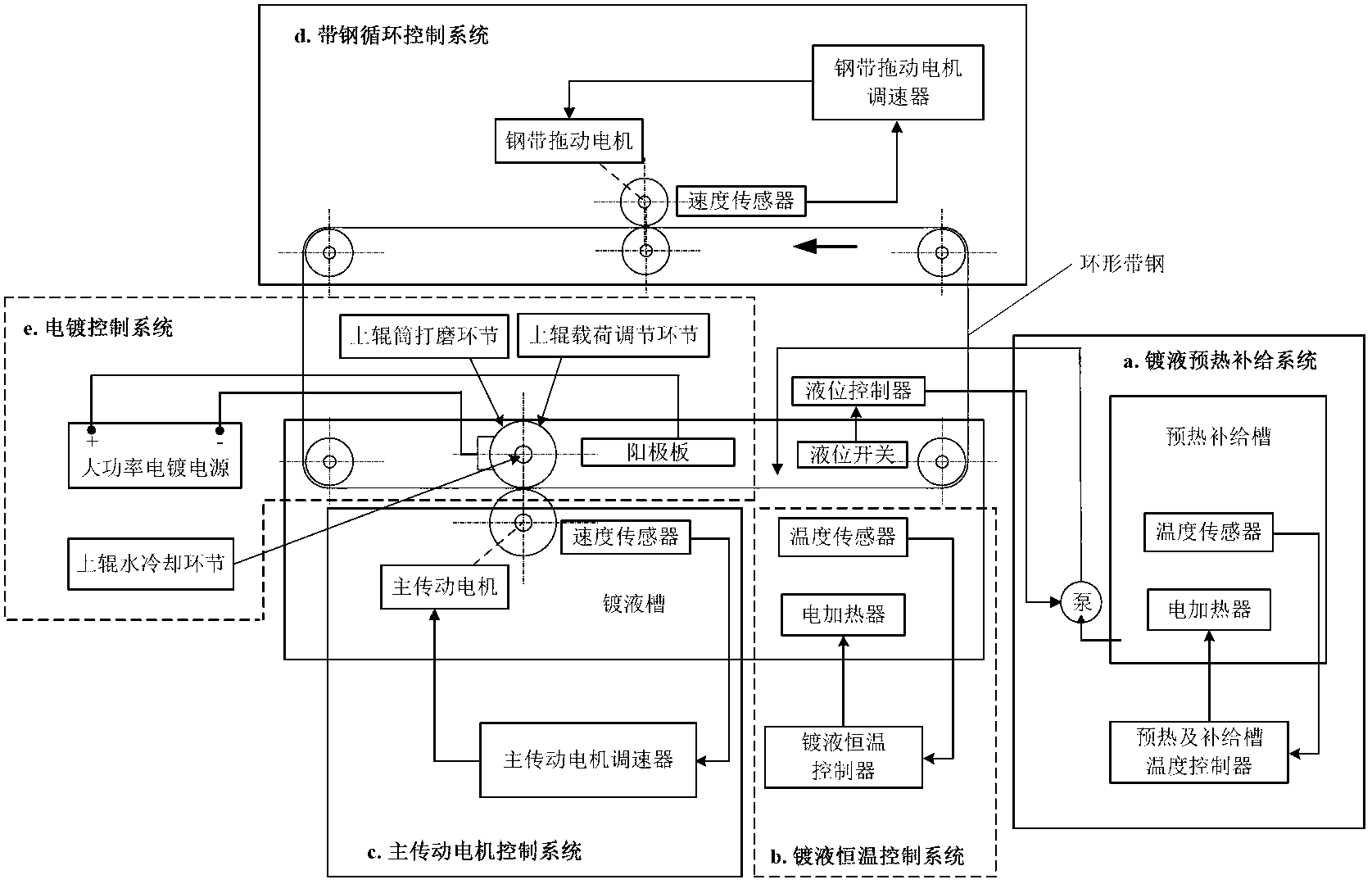

[0024] Please also see figure 1 and figure 2 , an experimental device for simulating the damage and failure of conductive roller materials under working conditions, including: a plating solution tank 1, an upper roller 2, a lower roller 3, a main drive speed regulating motor 4, a coupling 5, and upper and lower transmission gears 6 , a number of rolling bearings 7, sealing ring 8, collector ring 9, water cooling rotary joint 10, reversible motor 11, ball screw 12, upper roller grinding block 13, cooling water inlet 14, cooling water outlet 15, anode plate 16, conductive Carbon brush 17, preheating supply tank 18, preheating supply tank temperature sensor 19, preheating supply tank electric heater 20, liquid pump 21, bearing bracket 22, load regulator 23, endless strip steel 24, front guide roller 25, Rear guide roller 26, traction roller 27, strip steel driving mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com