Water injection coal sample gas diffusion initial velocity tester and testing method thereof

A technology of initial velocity and measuring instrument, which is applied in the direction of instruments, analytical materials, etc., can solve the problem of inability to measure the initial velocity of gas emission from wet coal samples, and achieve the effects of simple structure, high measurement efficiency and good simulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

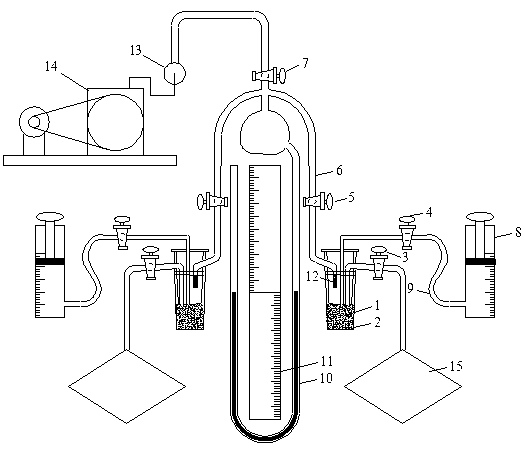

[0022] Such as figure 1 As shown, the water-injected coal sample gas release initial velocity measuring instrument of the present invention is mainly composed of a vacuum gauge 10, a coal sample tank 2 with a coal sample 1, a water injector 8, a scale 11, a vacuum pump 14, and a methane gas sample bag 15. The vacuum gauge 10 is connected with the vacuum pump 14, and the pipeline connecting the vacuum gauge 10 and the vacuum pump 14 is provided with a partition ball 13. The methane gas sample bag 15, the vacuum gauge 10, and the water injector 8 are respectively connected to the coal sample tank 2 through the pipeline, and enter the coal sample tank 2. The end of the branch vacuum tube 6 in the sample tank 2 is wrapped with cotton balls 12 . The vacuum gauge 10 is U-shaped, with scales 11 fixed therebetween, and the vacuum pump 14 pipeline connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com