Rapid determination method and device for ash content in lignocellulosic biomass fuel

A technology of biomass fuel and woody biomass, which is applied in the direction of weighing, analyzing materials, and instruments by removing certain components, can solve the problem that the efficiency and accuracy of ash content determination cannot be balanced, and achieve high accuracy of measurement results , less pollution, no need for manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

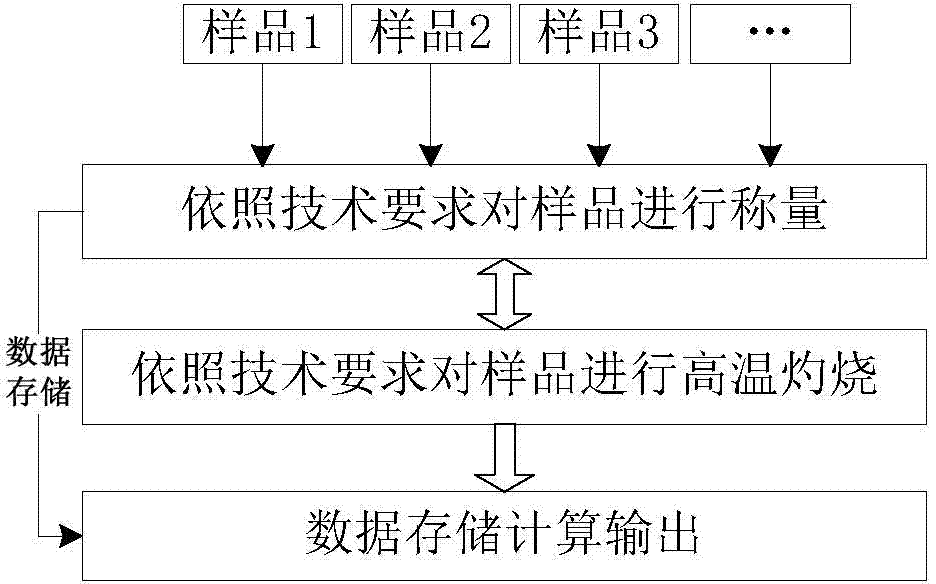

[0035] see figure 1 , the method for rapid determination of ash content in woody biomass fuel according to the first embodiment of the present invention, comprising:

[0036] Step 1, take an ash dish and burn it for 2 to 3 hours until it has a constant weight. During the burning process, the ash dish is gradually heated from room temperature to an ashing temperature of 575 ° C. After the burning is completed, the constant weight ash dish is weighed. The mass is recorded as m 0 , the ash dish after weighing is placed in a desiccator for backup;

[0037] In step 2, the tested biomass fuel is made into granules with a particle size of less than 0.2 mm, and a sample of tested biomass fuel with a mass of 0.50±0.05 g is taken out and spread evenly in the ash dish described in step 1, so that it is The mass per square centimeter is less than 0.15g, and the ash dish containing the tested biomass fuel sample is weighed, and its mass is recorded as m 1 ;

[0038] Step 3, put the ash...

Embodiment 2

[0048] The rapid determination method of the second embodiment of the present invention is basically the same as that of the first embodiment, and their differences are: the ashing temperature of the second embodiment is 575°C, the mass of a tested biomass fuel sample is 0.75g, and the horse-fired furnace is opposite to the tested biomass fuel sample. The burning time of biomass fuel samples was measured as 50min.

Embodiment 3

[0050] The rapid determination method in Example 3 of the present invention is basically the same as that in Example 1. The differences are: the ashing temperature of Example 3 is 600°C, the mass of a tested biomass fuel sample is 0.75 g, and the horse-fired furnace is opposite to the tested biomass fuel sample. The burning time of biomass fuel samples was measured as 50min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com