Determination method of silicon content in silicomanganese

A determination method and technology of silicon content, applied in the direction of color/spectral property measurement, etc., can solve the problems of cumbersome detection method steps, reduce detection cost, and long detection cycle, so as to meet industrial production needs, reduce measurement cost, and shorten detection cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

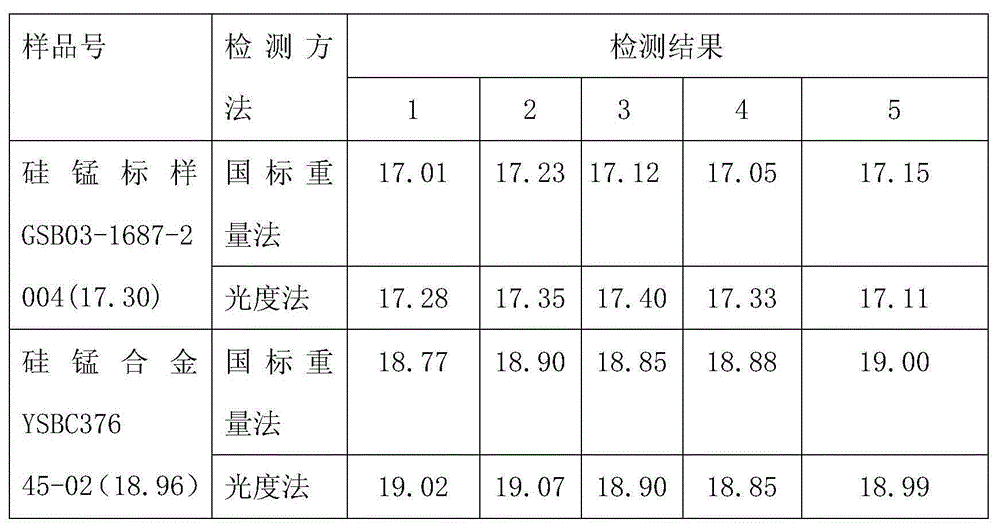

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below by way of examples.

[0023] A method for determining silicon content in silico-manganese, comprising the following steps: firstly melting a sample with sodium hydroxide, leaching it with hot water, adding sulfuric acid to acidify it, separating it at a constant volume, adjusting the pH, adding sulfuric acid nitric acid mixed acid and ammonium molybdate , Silicon in silicomanganese and ammonium molybdate generate silicomomolybdenum heteropolyacid, and finally add ferrous ammonium sulfate to reduce silicomomolybdenum heteropolyacid to silicomomolybdenum blue, and measure its absorbance with a spectrophotometer at a wavelength of 680nm.

[0024] The assay method of silicon content in described silicon manganese, concrete steps are as follows:

[0025] (1) Weigh 0.100g of a sample accurate to 0.0001g and place it in a nickel crucible, add 3g of sodium hydroxide, mix well, place the sample on an electric furnace and he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com