Corrosion-resistant evaluation test method for large-diameter seamless line pipe

A seamless line pipe, evaluation test technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring device, instrument, etc., can solve the problem that the test method cannot accurately obtain the exact result, the comparative test and elaboration, and the test result is inaccurate and other problems, to achieve the effect of predicting environmental application performance, good reproducibility, and reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

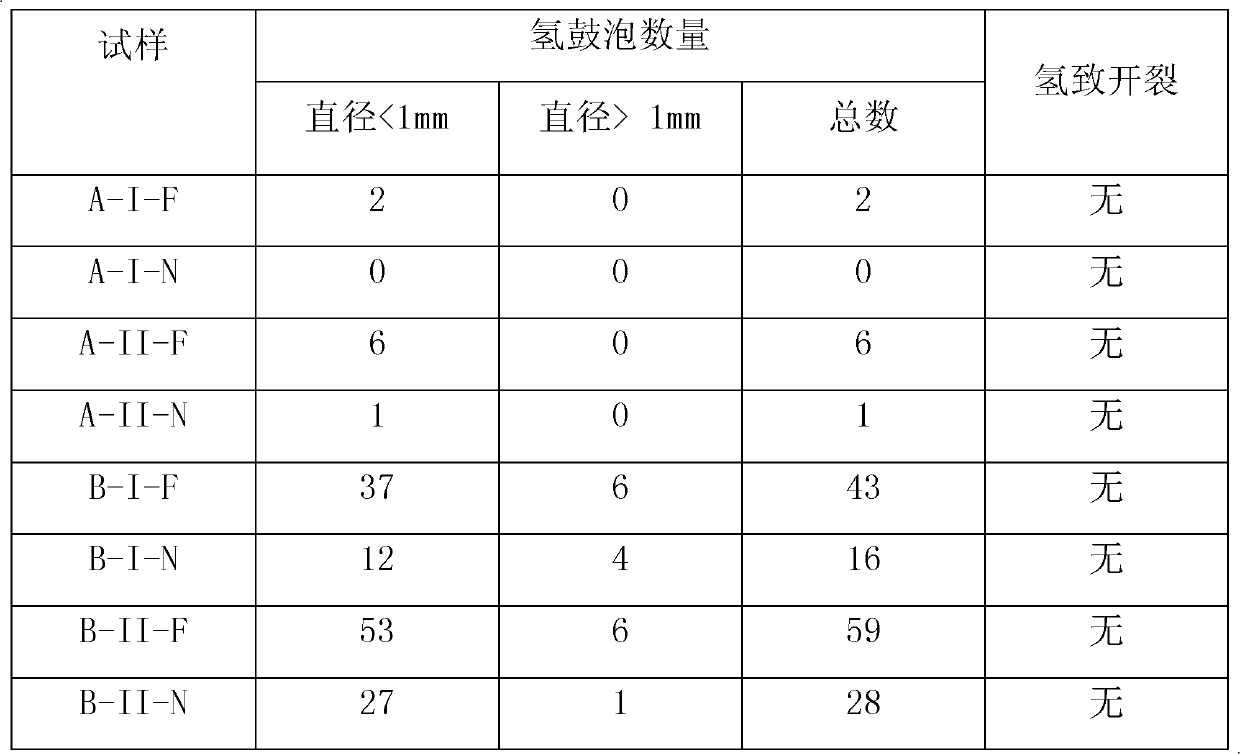

Examples

Embodiment Construction

[0025] The corrosion resistance evaluation test method of large diameter seamless line pipe of the present invention, the test method includes seamless line pipe sample test pretreatment method, corrosion evaluation test, sample treatment after test, comparison of different test conditions, test report ,Proceed as follows:

[0026] I. Pretreatment method of sample test

[0027] The size of the line pipe sample is 305×38×13mm, and it is divided into two kinds of samples according to the surface roughness. Marking; the other is direct marking without surface treatment; use wire cutting equipment to slot along the middle thickness direction of the sample, and use ultra-high-strength special molybdenum wire for wire cutting. The molybdenum wire has a diameter of 0.2mm and a groove depth of 2mm;

[0028] II. Corrosion evaluation test

[0029] Make the above two samples into a group, put the slots of the two samples outward, and support the 25.5mm places on the left and right side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com