Manufacturing method and repair wire structure of display panel

A manufacturing method and display panel technology, applied in the fields of nonlinear optics, instruments, optics, etc., can solve problems such as pixel electrodes cannot obtain data signals, liquid crystal panel display defects, signal line disconnection, etc., and achieve the effect of improving process yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

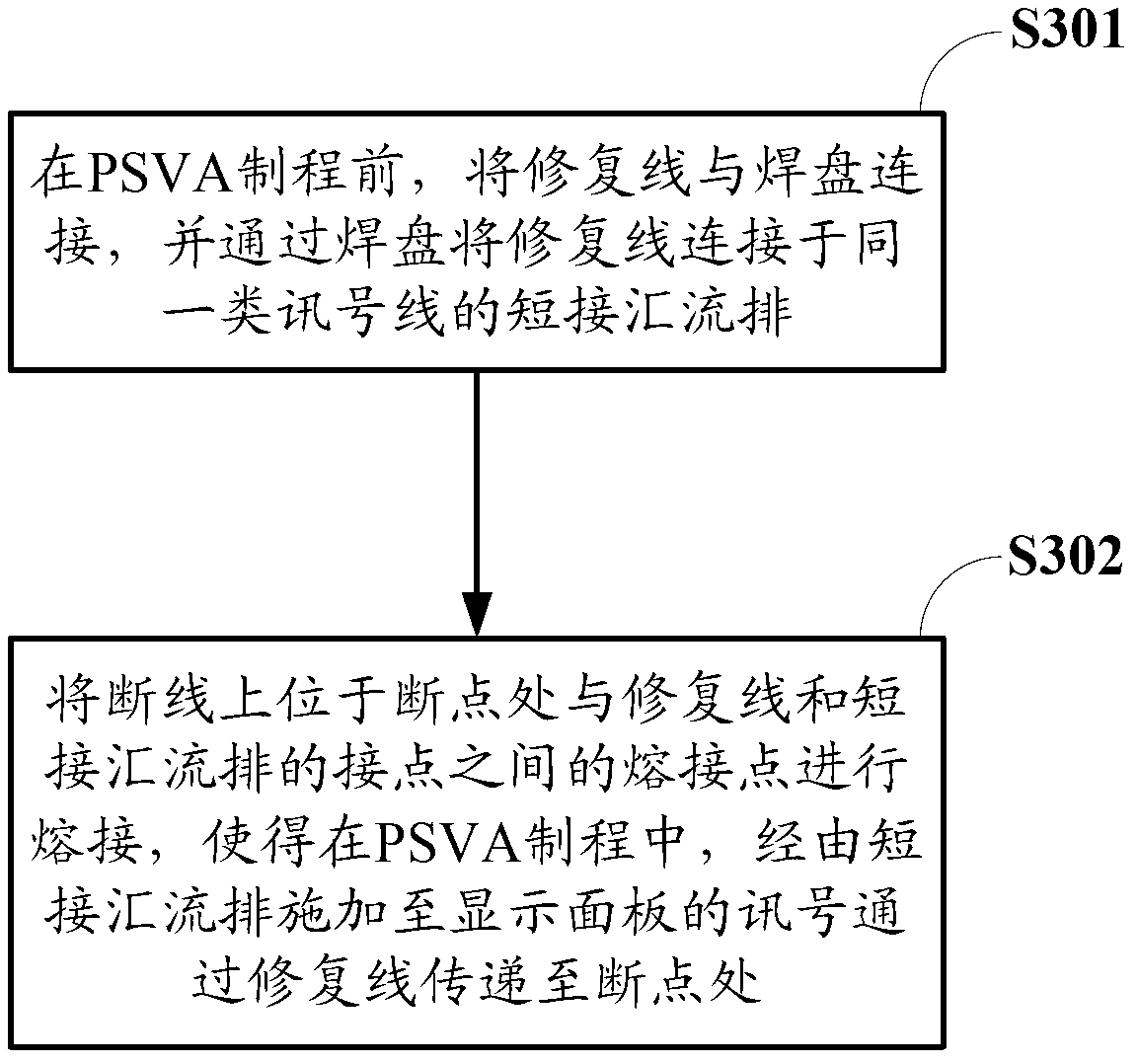

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

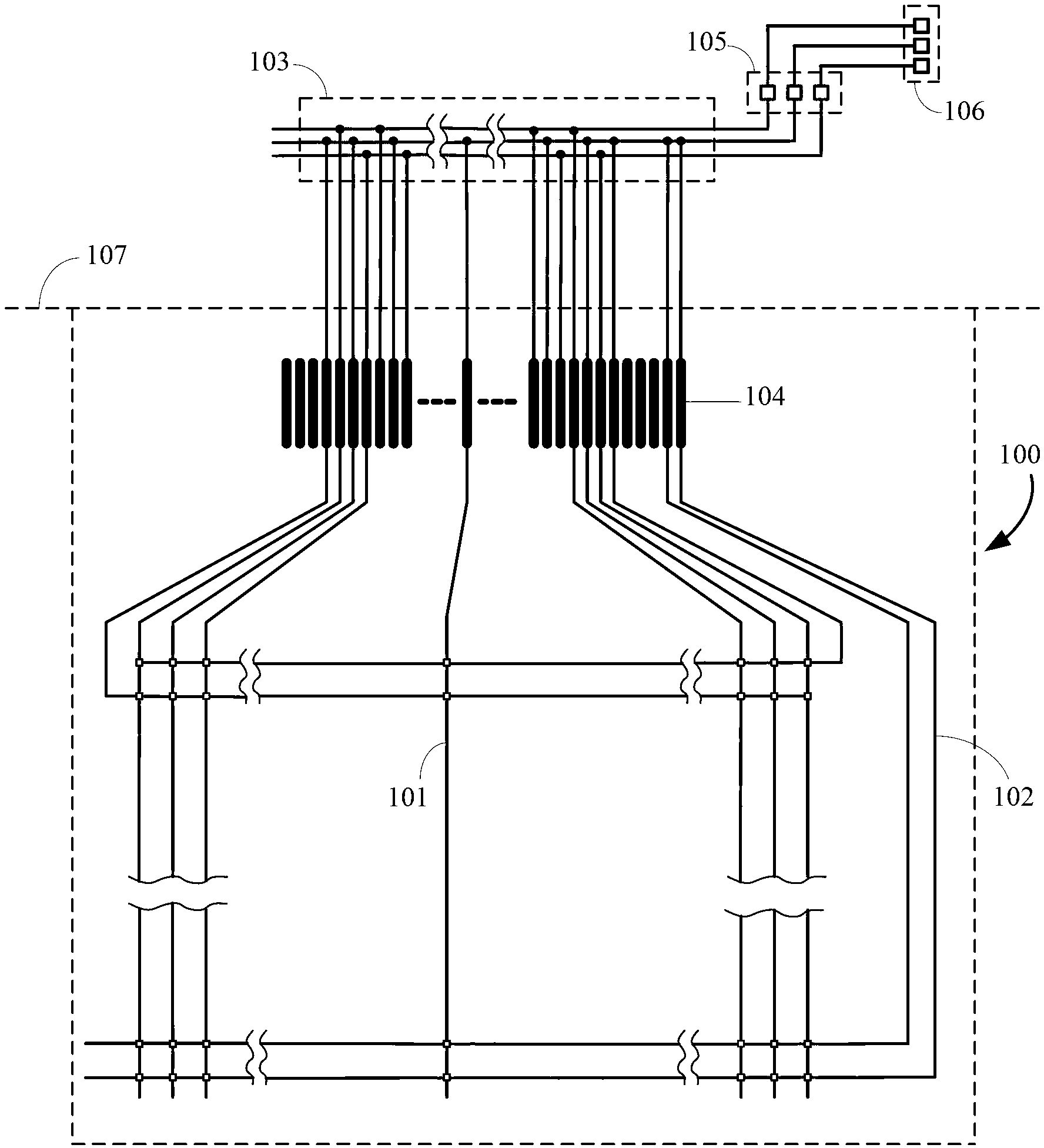

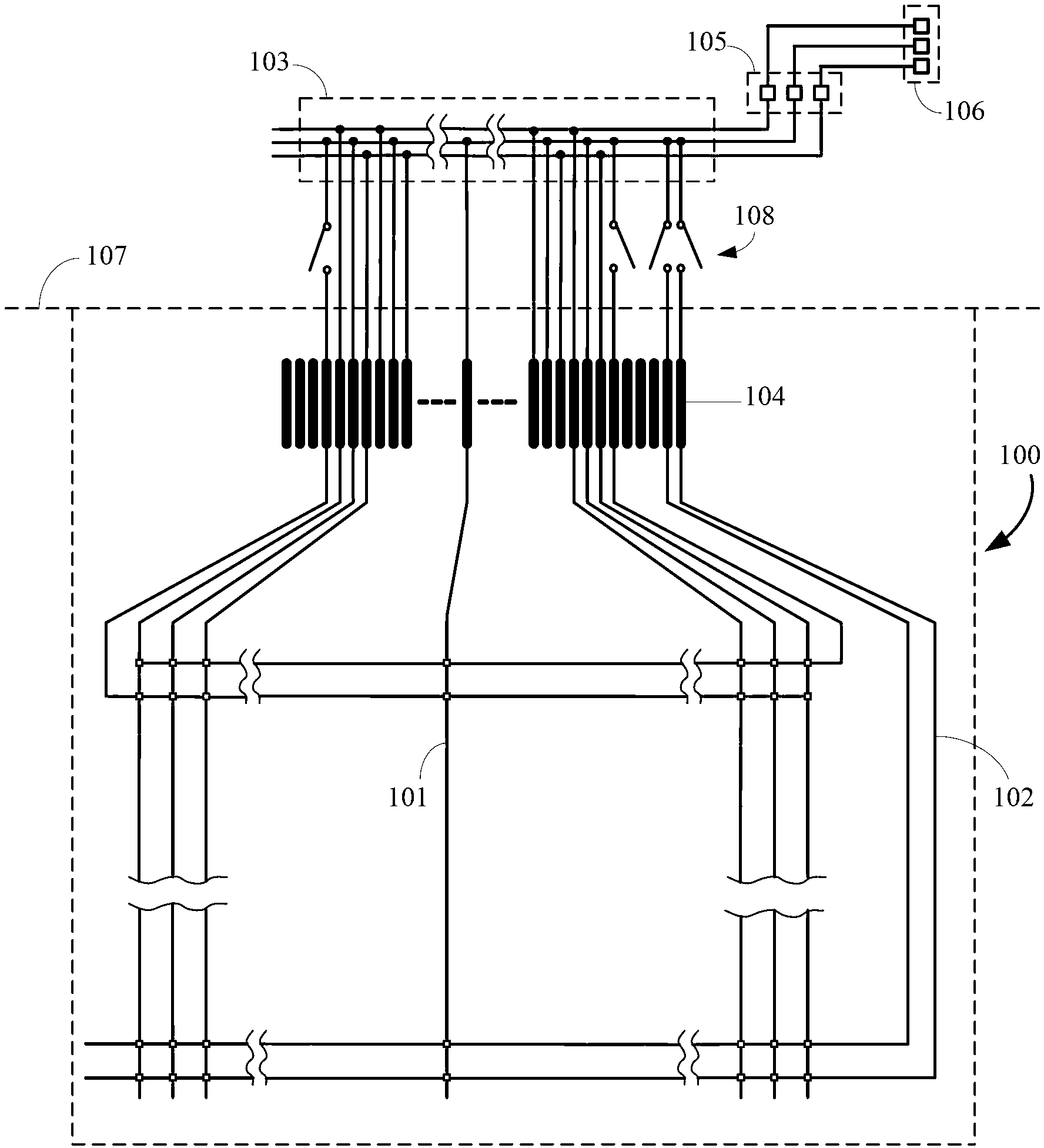

[0024] figure 1 It is a structural schematic diagram of the first embodiment of the repair line structure of the display panel of the present invention. Such as figure 1 As shown, the repair line structure of the display panel 100 includes: a plurality of signal lines 101 , a plurality of repair lines 102 , a shorting bus bar 103 , a pad 104 , a test pad 105 and an alignment voltage application pad (PSVApad) 106 .

[0025] Wherein, the signal line 101 generally refers to the driving wiring of the display panel 100 , such as a scan line or a data line.

[0026] Wherein, the shorting bus bar 103, the test pad 105 and the alignment voltage application pad 106 are located on one side of the panel cutting line 107, and the plurality of signal lines 101, the plurality of repair lines 102 and the pads 104 are located on the other side of the panel cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com