Method for realizing BOM (Bill of Material) information transmission between PDM (Product Data Management) system and ERP (Enterprise Resource Planning) system

An ERP system and information transmission technology, applied in the field of BOM information transmission between the PDM system and the ERP system, can solve the problems of poor versatility, fixed structure of intermediate files and intermediate data tables, low operability and data security, etc. problem, to achieve the effect of not being easy to make mistakes, overcoming misoperation of BOM information input, and avoiding repeated data input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for realizing BOM information transmission between the PDM system and the ERP system proposed in this embodiment, its basic idea is to input BOM information to the ERP system by simulating the manual input method, which includes the following steps:

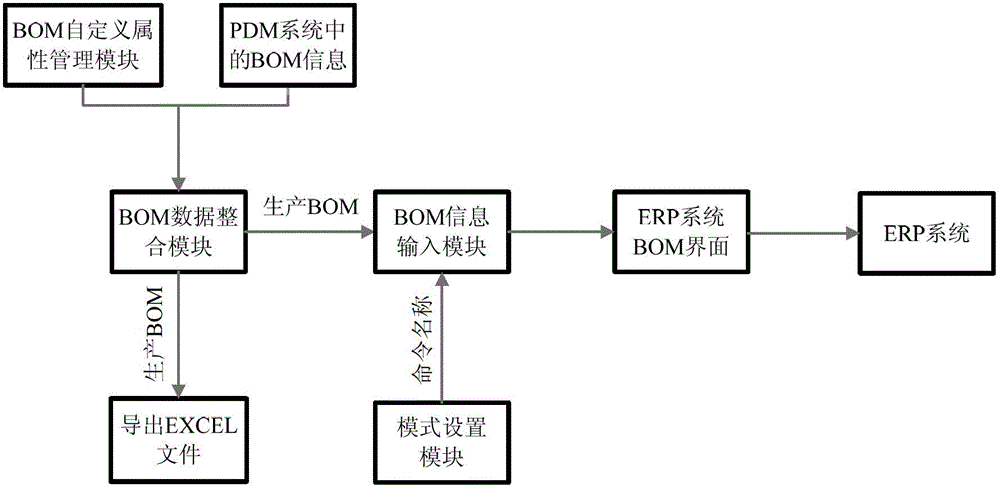

[0032] ①-1, such as figure 1 As shown, a BOM transmission interface is set between the PDM system and the ERP system. The BOM transmission interface has a BOM information input port connected to the port used to output BOM information in the PDM system and a port used to input BOM information in the ERP system. The BOM information output terminal connected to the BOM information port, the composition structure of the BOM transmission interface is as follows figure 2 As shown, it is equipped with BOM custom attribute management module, BOM data integration module, mode setting module and BOM information input module, the input end of BOM data integration module is connected with the output end of BOM custom attrib...

Embodiment 2

[0048] The BOM information transmission method of this embodiment is based on the BOM information transmission method of Embodiment 1, in step ①-1, the output end of the BOM data integration module is connected with the input end of the entry approval module in the PDM system, Connect the output of the input approval module in the PDM system with the input of the BOM information input module; submit the integrated production BOM information conforming to the ERP system format to the input approval module in the PDM system in steps ①-4 , the input approval module in the PDM system reviews the production BOM information, and transmits the reviewed production BOM information to the BOM information input module. In this embodiment, the main function of the entry approval module in the PDM system is to submit the production BOM information sent by the BOM data integration module to the PDM system, and in the PDM system, review the production BOM information according to the predeter...

Embodiment 3

[0050] A kind of method that this embodiment proposes realizes BOM information transmission between PDM system and ERP system, its basic idea is to simulate ERP system client to send BOM information to ERP system server, it comprises the following steps:

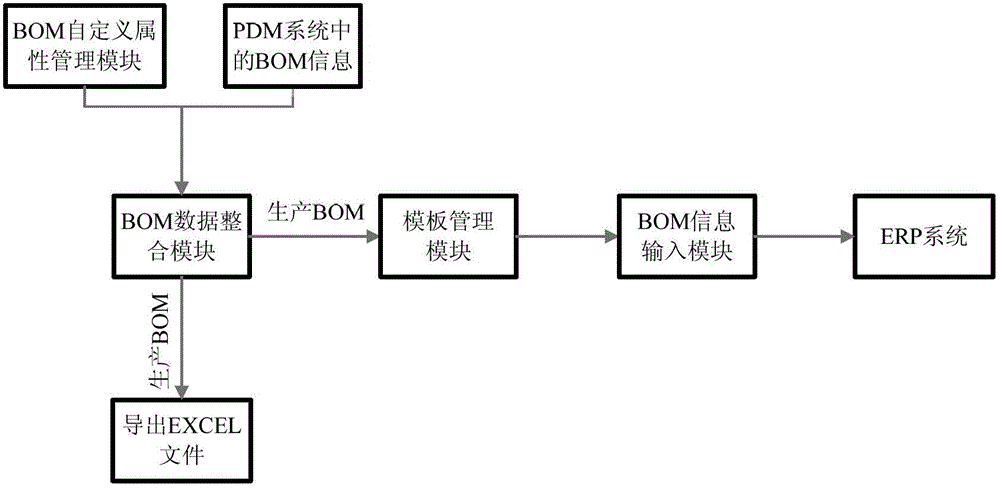

[0051] ②-1. Set up a BOM transmission interface between the PDM system and the ERP system. The BOM transmission interface has a BOM information input port connected to the port used to output BOM information in the PDM system and a port used to output BOM information in the ERP system. The BOM information output terminal connected to the port for inputting BOM information, the structure of the BOM transmission interface is as follows image 3As shown, it is equipped with BOM custom attribute management module, BOM data integration module, template management module and BOM information input module, the input end of BOM data integration module is respectively connected with the output end of BOM custom attribute management mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com