A Multi-Cock System for Accelerator-Driven Subcritical Stack Refueling

An accelerator-driven, subcritical technology, applied in the field of multi-cock systems, can solve the problems of reduced range of movement of small cocks, inability to realize the functions of control rod systems, and no detailed description, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

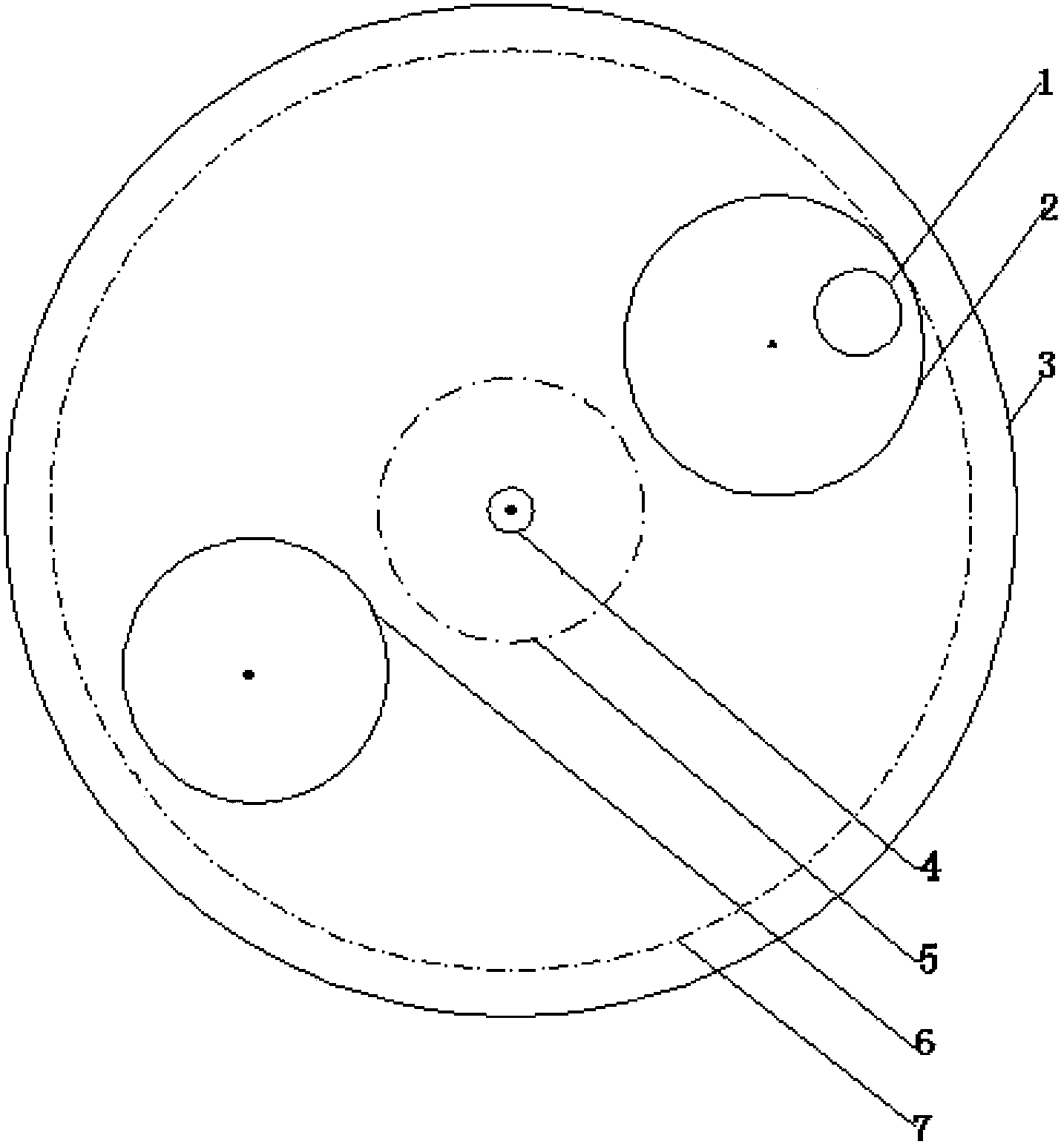

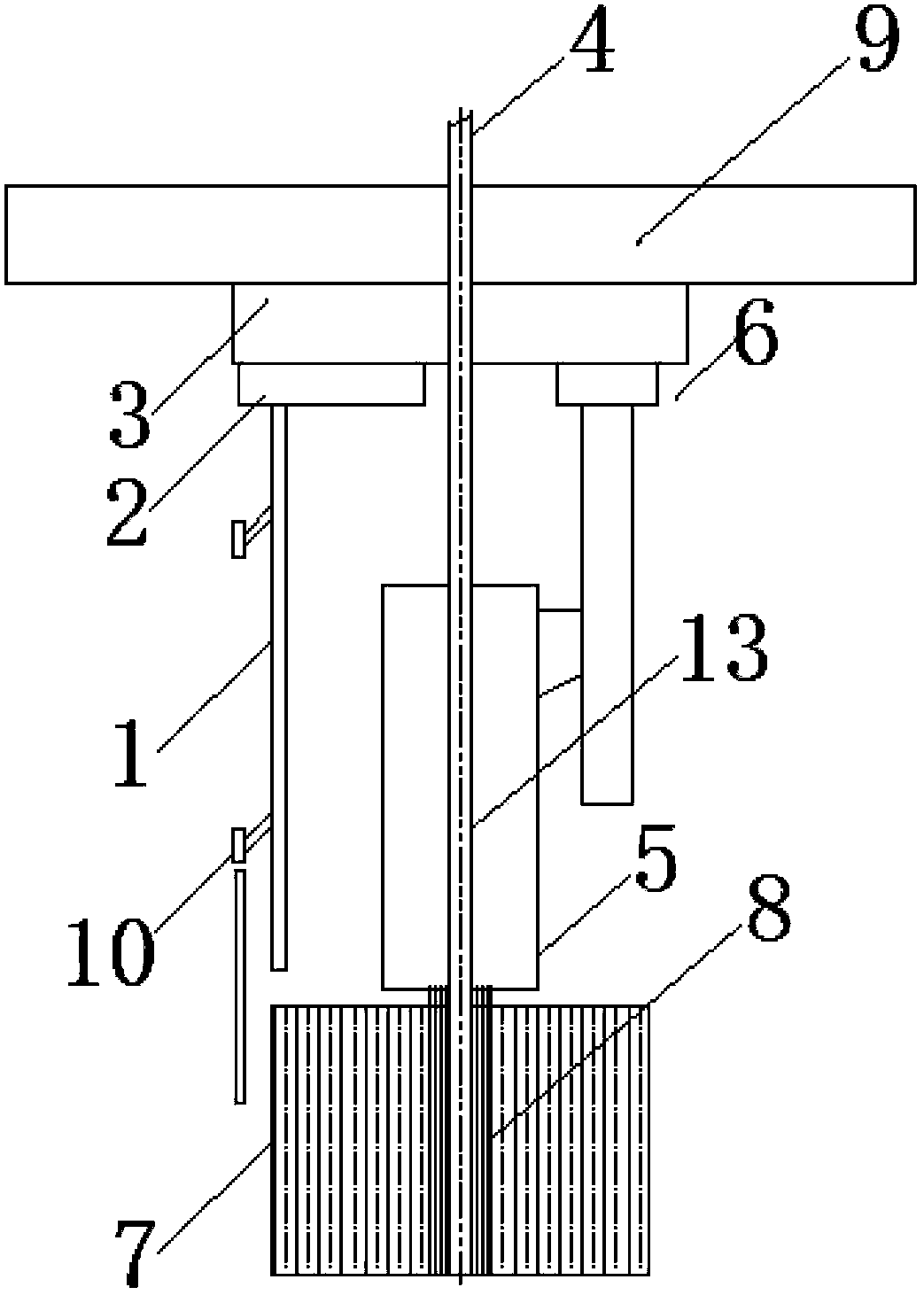

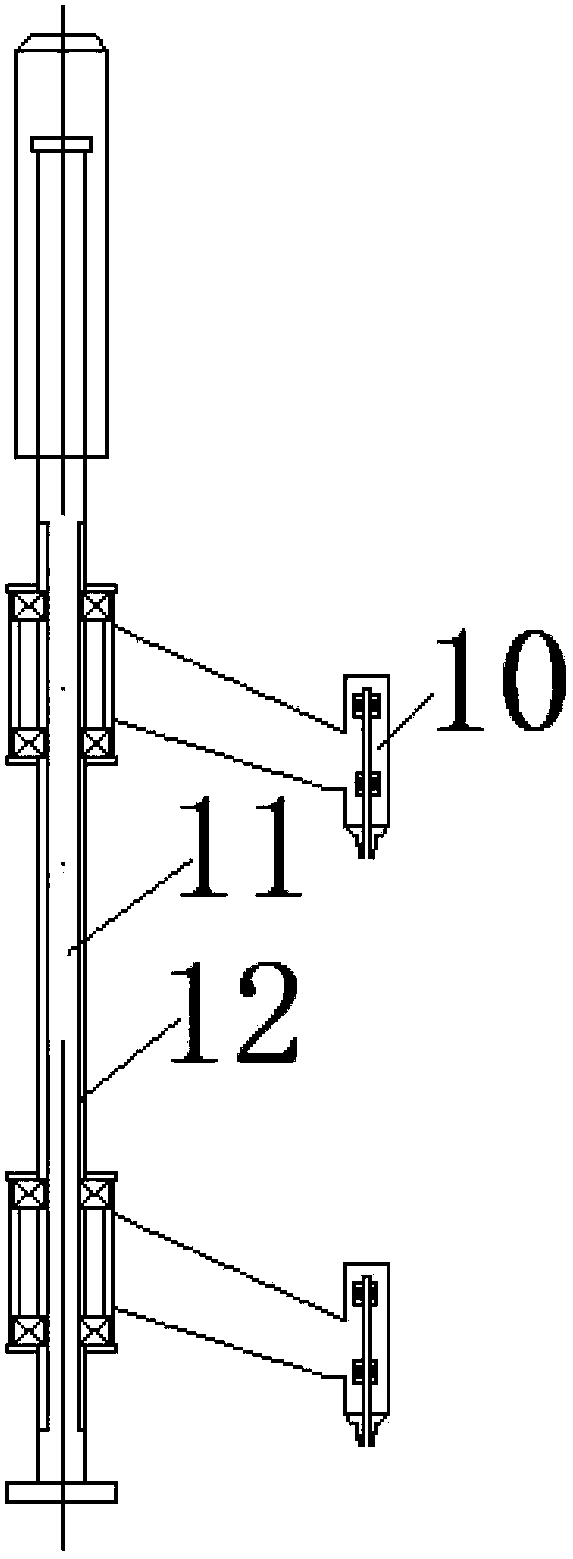

[0022] Such as figure 1 As shown, the present invention includes a refueling machine 1, a first small cock 2, a large cock 3, an accelerator proton beam tube 4, a control deflection barrel 5, a second small cock 6 and a control rod system 8; the first small cock 2 and the first The second small cock 6 is installed on the large cock 3, the refueling machine 1 is installed on the first small cock 2, the control deflection barrel 5 is connected to the second small cock 6, the accelerator proton beam tube 4 passes through the center of the large cock 3 and is connected with The large cock 3 is coaxial, and the control rod system 8 is arranged on the control deflection barrel 5; the first small cock 2 and the second small cock 6 are respectively eccentric to the large cock 3, and the refueling machine 1 is eccentric to the first small cock 2 to control the deflection The barrel 5 is eccentric with the second small cock 6; the control deflection barrel 5 is equipped with a control r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com