GaN-based LED

A light-emitting diode, gallium nitride-based technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of excessive axial light emission from the front, uneven distribution of LED light emission, and small light emission angle, etc., to enhance the probability of light emission , Improve the uniformity of light distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

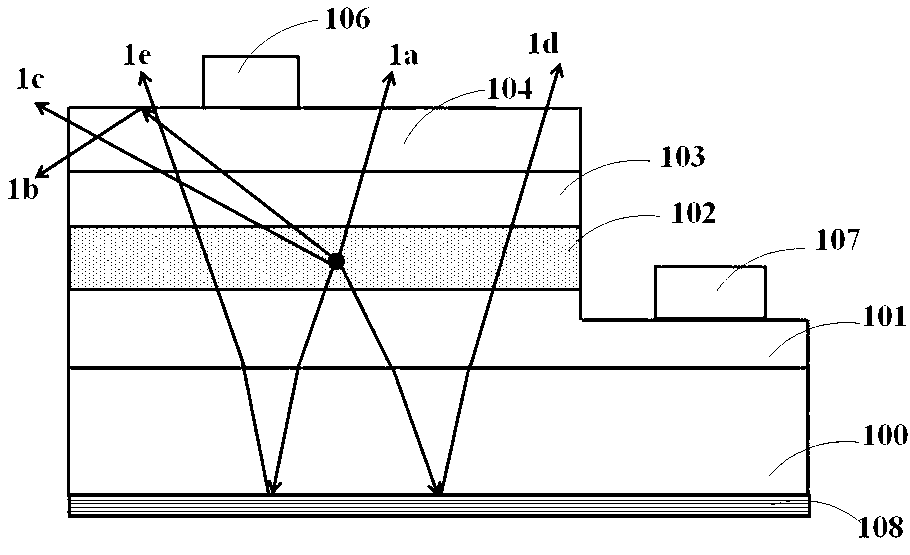

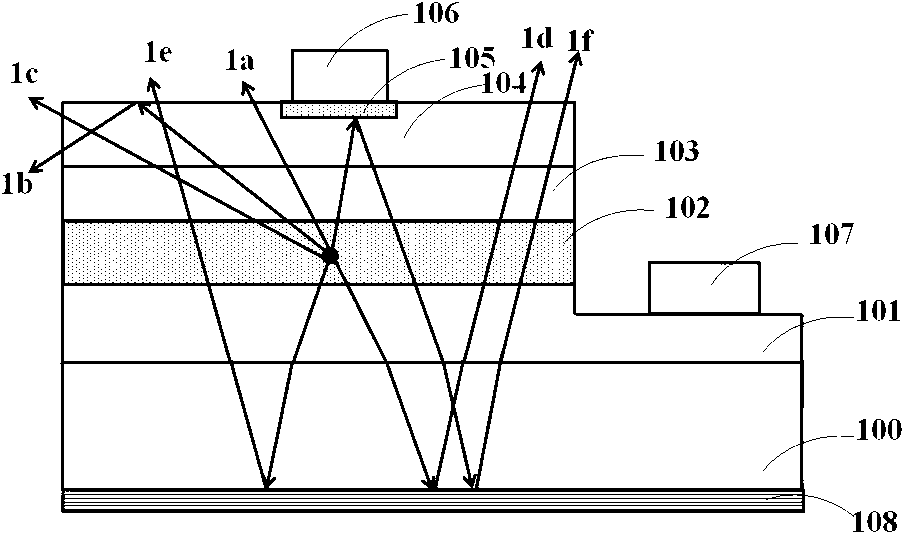

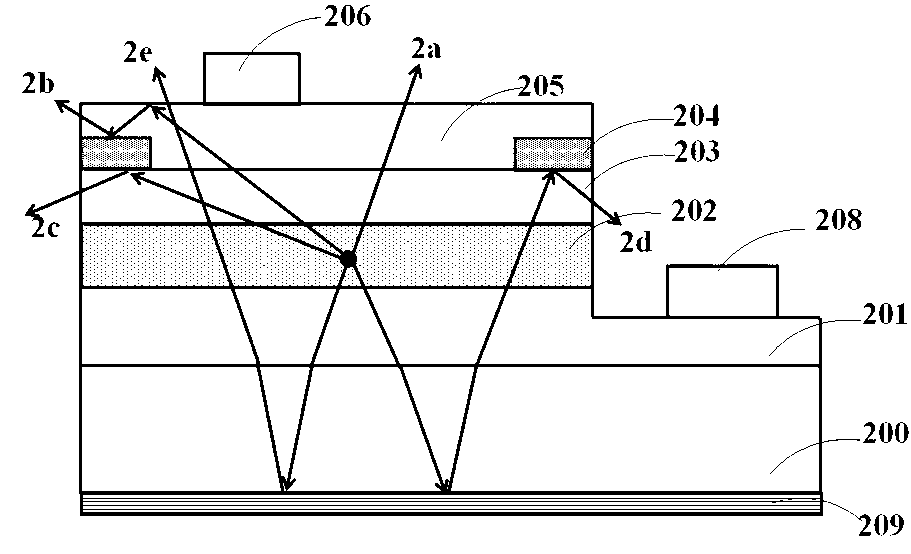

[0071] Such as image 3 and Figure 4 The gallium nitride-based high-brightness light-emitting diode shown includes: a sapphire substrate 200, an N-type layer 201, a light-emitting region 202, a P-type layer 203, a non-closed ring-shaped first reflective layer 204, and a current spreading layer 205 , P electrode 207, N electrode 208 and second reflective layer 209.

[0072] Specifically, the bottommost layer in the above light emitting diode structure is the sapphire substrate 200; the N-type layer 201 is formed on the sapphire substrate 200; the light-emitting region 202 is formed on the N-type layer 201; the P-type layer 203 is formed on the light-emitting region 202 The first reflective layer 204 is a distributed Bragg reflective layer, formed on the P-type layer 203 and distributed on the edge region of the P-type layer 203 away from the P-electrode, with a strip width of 15 microns and an area accounting for 10% of the light-emitting area of the epitaxial layer About ...

Embodiment 2

[0075] Such as Figure 5 and Figure 6 The gallium nitride-based high-brightness light-emitting diode shown includes: a sapphire substrate 200, an N-type layer 201, a light-emitting region 202, a P-type layer 203, a closed-loop first reflective layer 204, a current spreading layer 205, The third reflective layer 206 , the P electrode 207 , the N electrode 208 and the second reflective layer 209 .

[0076] Specifically, the bottommost layer in the above light emitting diode structure is the sapphire substrate 200; the N-type layer 201 is formed on the sapphire substrate 200; the light-emitting region 202 is formed on the N-type layer 201; the P-type layer 203 is formed on the light-emitting region 202 . The first reflective layer 204 is a distributed Bragg reflective layer, formed on the P-type layer 203 and distributed in the edge region of the surface of the P-type layer 203 . The strip width of the first reflective layer is 20 microns, and its area accounts for about 25% ...

Embodiment 3

[0080] Compared with Embodiment 2, this embodiment discloses a gallium nitride-based high-brightness light-emitting diode with a vertical structure and a reflective layer structure. In this embodiment, Si is used as the substrate 200, and the N electrode 208 is formed on the back of the substrate, forming a vertical LED device structure. The third reflective layer is an omnidirectional reflective layer with a diameter of 70 microns, and the diameter of the third reflective layer 206 is smaller than that of the P electrode, which facilitates the contact and conduction between the P electrode and the current spreading layer 205 .

[0081] To sum up, the main design spirit of the reflective layer structure of the present invention lies in: (1) the first reflective layer can be in the form of a closed ring or an open ring; (2) the reflective layer with (ring) shape The edge region coincides with the edge region of the surface of the epitaxial layer. Through the reasonable design ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com