Electric trolley battery heating method

A battery heating and electric vehicle technology, which is applied to secondary batteries, circuits, electrical components, etc., can solve the problems of battery damage and the influence of temperature difference of battery cells, etc., and achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

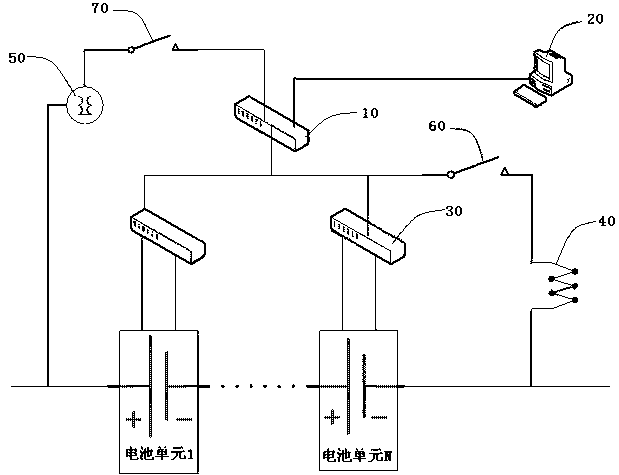

[0016] The electric vehicle battery heating method of the present invention will be further described in detail in conjunction with specific embodiments and accompanying drawings.

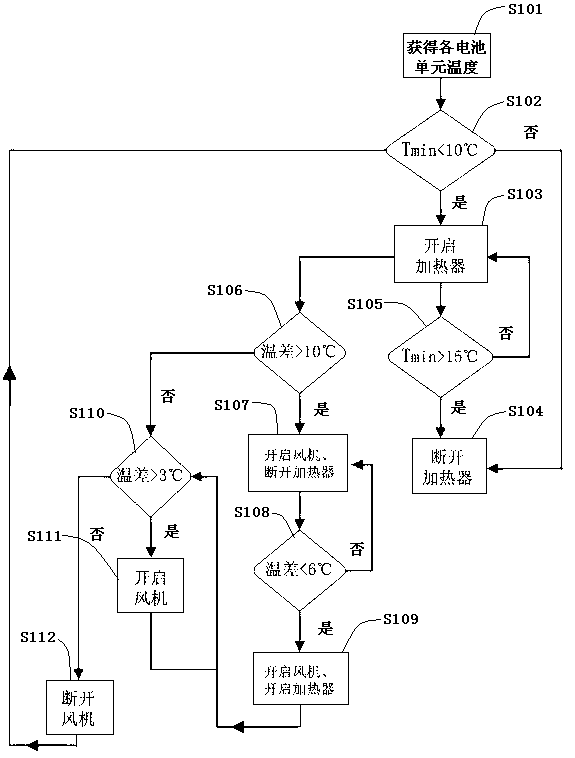

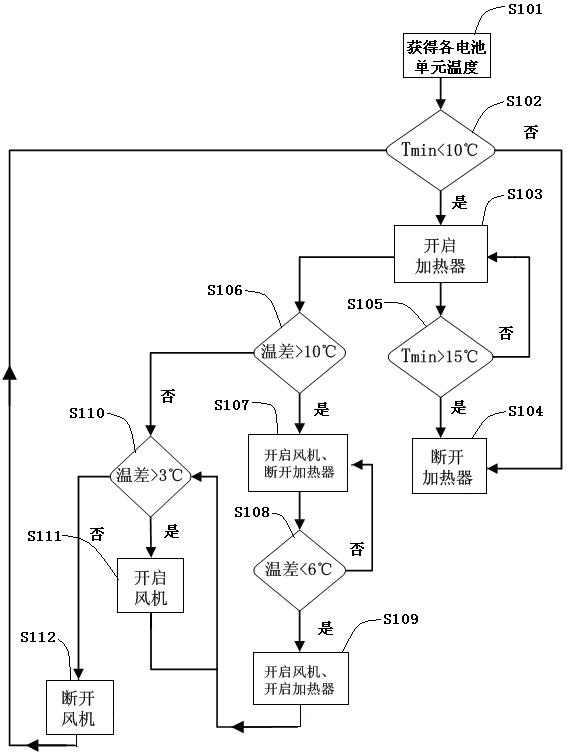

[0017] The electric car battery heating method of the present invention is suitable for electric car batteries, especially a battery pack composed of a plurality of single lithium ion batteries connected in series and parallel. We know that the charging current of a lithium battery is closely related to the temperature. For example, when the battery temperature is lower than 0°C, the lithium ion battery cannot be charged. Therefore, the problem of how to fully charge the lithium-ion battery pack in a short time has actually turned into a problem of how to raise the temperature of the battery to an acceptable high-current charging range in a short time. The invention adopts the control strategy of heating the battery pack with a heater and using a fan to assist in the balanced distribution of heat, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com