Cheese-containing food and method for producing same

A manufacturing method and cheese technology, applied in cheese substitutes, dairy products, applications, etc., can solve problems such as easy burning, oil production, and large temperature deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

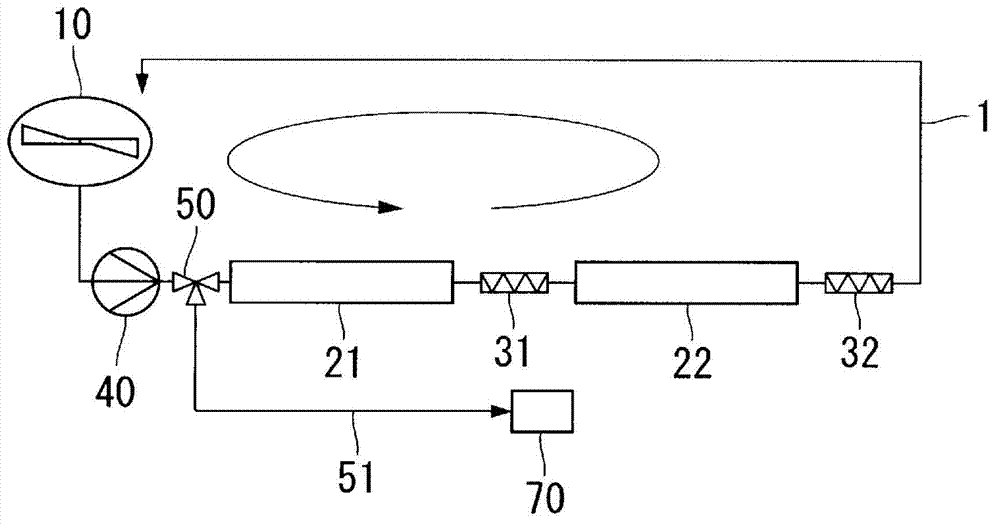

[0052] The apparatus used in the production method of the first embodiment of the present invention is shown in figure 1 . figure 1 A high-speed shear digester 10 and Joule heaters 21 and 22 are arranged in sequence on the annular flow path 1 . In addition, a pump 40 is provided on the downstream side of the high-speed shear digester 10, and static mixers 31 and 32 are provided on the downstream sides of the Joule heaters 21 and 22, respectively. In addition, a three-way valve 50 is provided downstream of the pump 40 and upstream of the Joule heater 21 , and a branch flow path 51 is branched from the three-way valve 50 .

[0053] The high-speed shear cooker 10 is a device that stirs while shearing an input material with a cutting blade rotating at a high speed. Here, "high-speed rotation" means that two or more cutting blades rotate at 750 rpm or more. The rotational speed of the cutting blade of the high-speed shear digester 10 is preferably 1000 rpm or more, more prefer...

no. 2 Embodiment approach

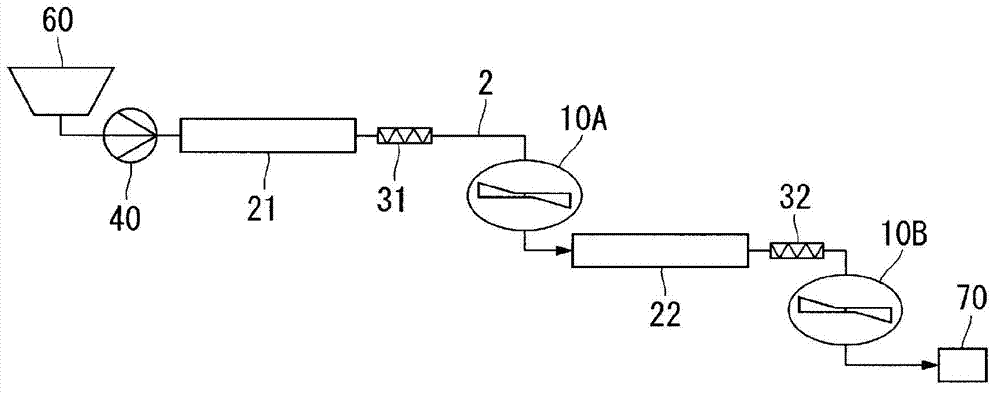

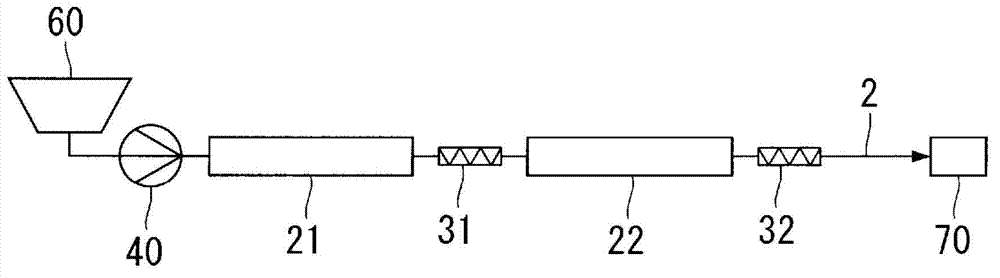

[0066] The apparatus used in the production method of the second embodiment of the present invention is shown in figure 2 . exist figure 2 in, with figure 1 The same constituent parts are attached with figure 1 The same symbols are used, and detailed explanations are omitted.

[0067] figure 2 The device is that a Joule heater 21, a high-speed shear cooker 10A, a Joule heater 22, and a high-speed shear cooker are sequentially arranged on the serial flow path (non-circular flow path) 2 starting from the low-speed rotary melting tank 60 10B. That is, Joule heaters and high-speed shear cookers are alternately installed.

[0068] In addition, a pump 40 is installed on the downstream side of the low-speed rotary melting tank 60 , and static mixers 31 and 32 are installed on the downstream sides of the Joule heaters 21 and 22 , respectively.

[0069] High shear digesters 10A and 10B with figure 1 The high shear digester 10 is the same.

[0070] use figure 2 In the c...

Embodiment 1

[0136] (raw material)

[0137] The raw materials of soft cheese mixture are the component ratios shown below.

[0138] In addition, the fat content in each raw material was calculated|required by Lou-Gauer's method. The protein content in each raw material was calculated|required by the Kjeldahl method. The moisture content in each raw material was calculated|required by the sand mixing drying method.

[0139] Cream cheese (Australian Cream Cheese made by Kraft Foods Inc.): 180kg

[0140] Fat content: 34% by mass

[0141] Protein content: 8% by mass

[0142] Fat / Protein Mass Ratio: 4.2

[0143] Moisture content: 54% by mass

[0144] Butter (unsalted butter made by Morinaga Dairy Co., Ltd.): 5kg

[0145] Fat content: 83% by mass

[0146] Protein content: 0.5% by mass

[0147] Fat / protein mass ratio: 166.2

[0148] Moisture content: 15.5% by mass

[0149] TMP (Promilk 85Y manufactured by Ingredia): 4kg

[0150] Fat content: 1% by mass

[0151] Protein content: 81% b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com