Energy-saving circulating steamer

A circulation type, steamer technology, applied in the field of steamer, can solve the problems of heat loss, speed up food heating speed, speed up steam, etc., to achieve faster heating speed, short cooking time, good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

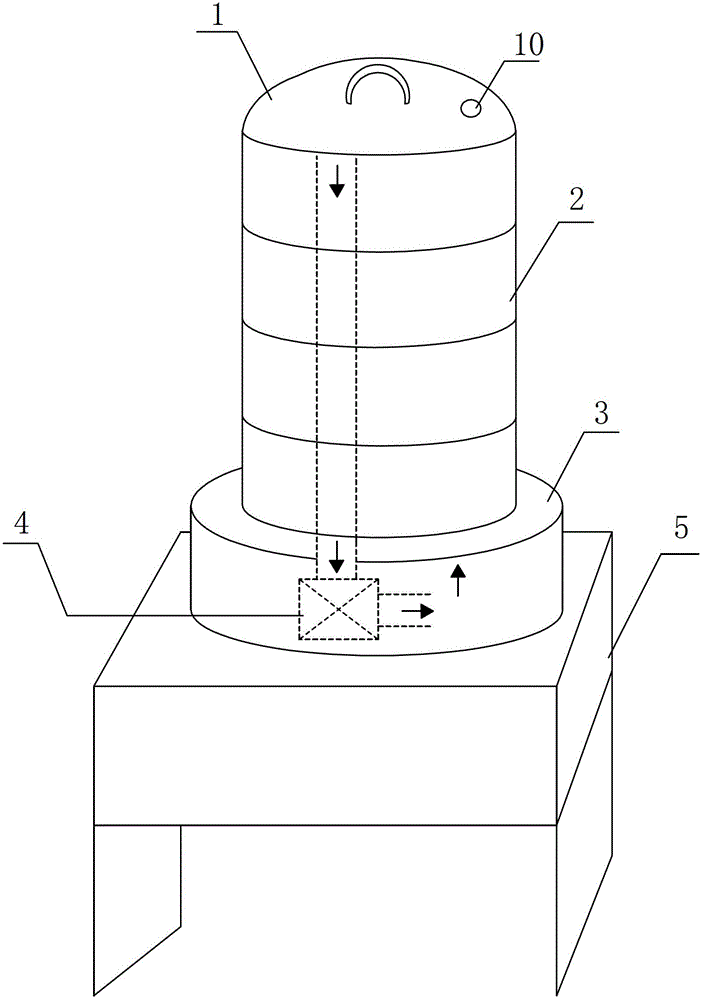

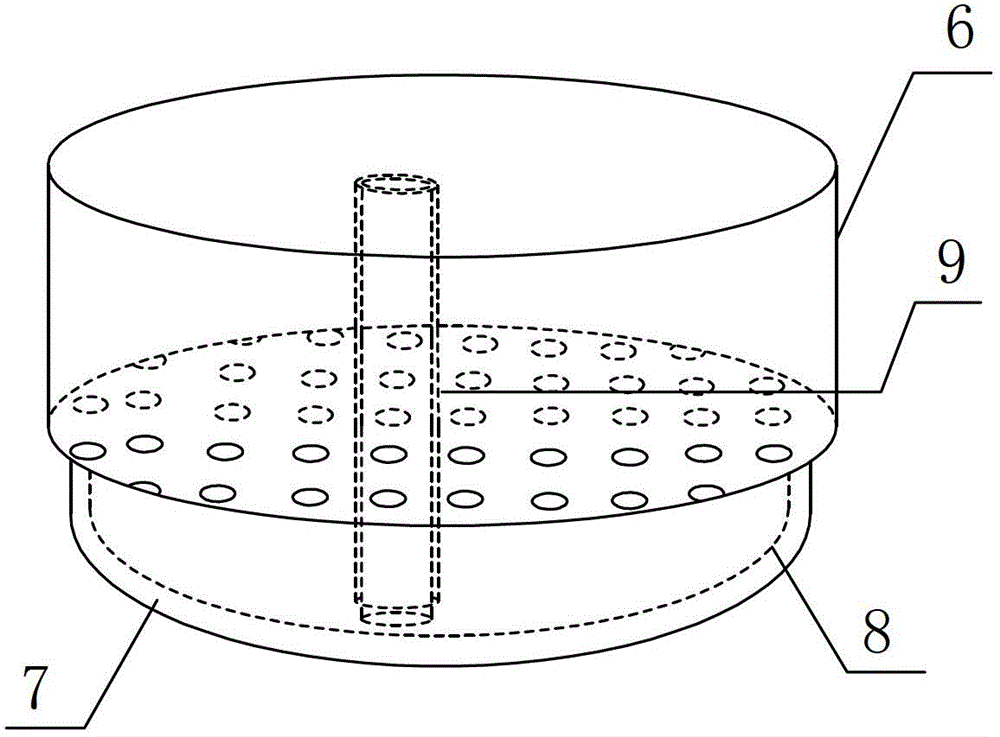

[0020] Such as figure 1 As shown, the energy-saving circulating steamer includes a steamer body 2, a steamer base 3 and a steam oven 5, the steamer body 2 is arranged on the upper part of the steamer base 3, and the lower part of the steamer base 3 is provided with a steam oven 5, and the steamer body 2 includes multiple Layers of steamer drawers 6 superimposed on each other and the sealed steamer cover 1 covered on the uppermost steamer drawer 6 also include a pipeline for recovering steam. 4 is connected to the air inlet, and the air outlet of the air extractor 4 is connected to the steam furnace 5 through a pipeline; a sealing member to prevent steam from escaping is provided on the joint surface of each layer o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com