Heat-insulating and energy-saving metal rice steaming lattice

A metal and rice-steaming technology, used in cooking utensils, household appliances, applications, etc., can solve the problems of airtight steaming grids and invisible structures, and achieve the effects of material saving, convenient use and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

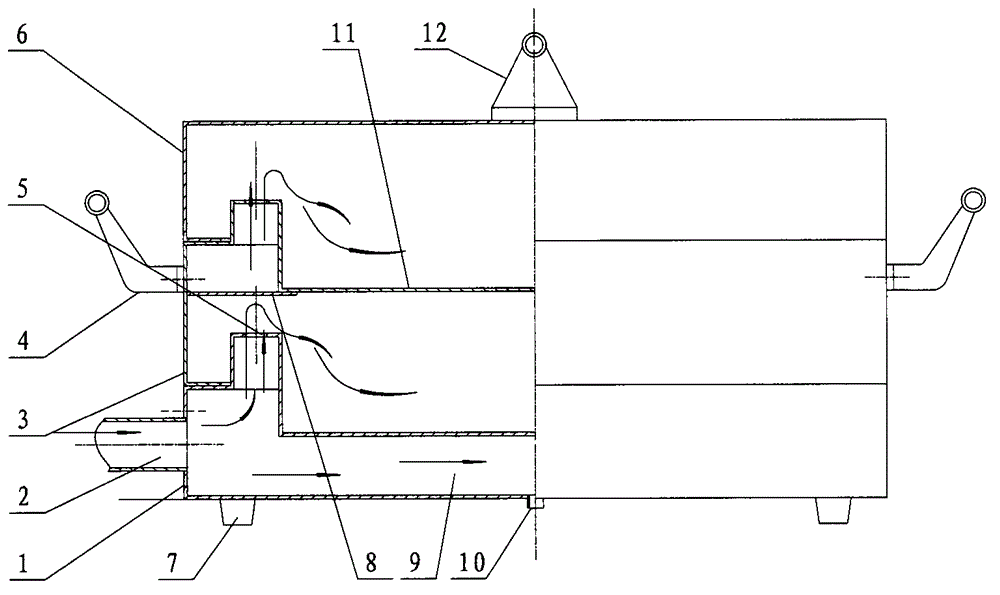

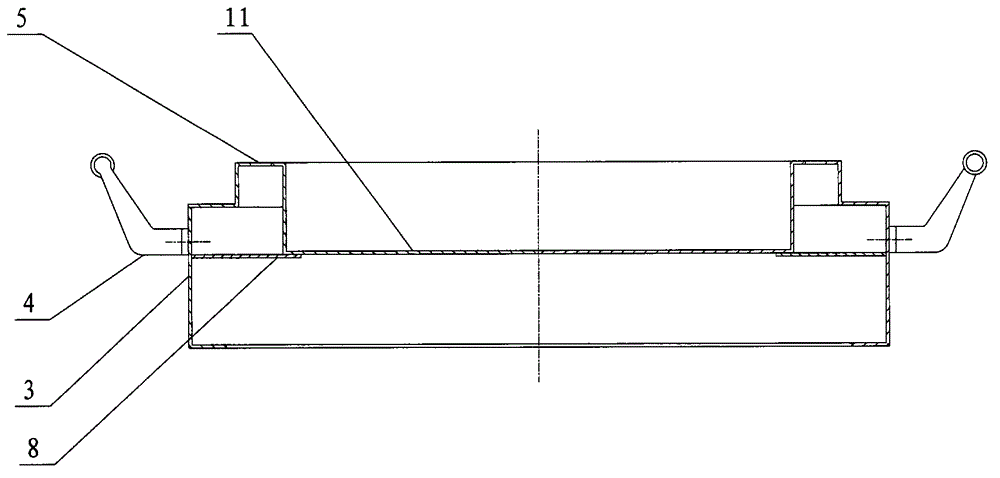

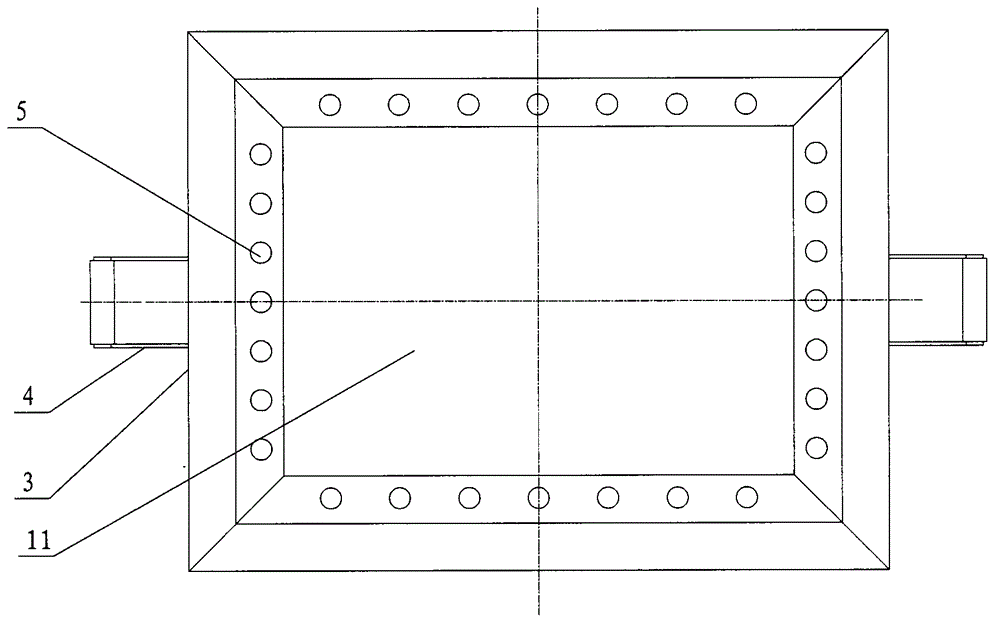

[0023] Such as figure 2 , image 3 , Figure 4 and Figure 5 , a heat preservation and energy-saving metal rice steamer, characterized in that: the rice steamer 3 includes a rectangular stainless steel basin 11 and a stainless steel profile located at the periphery of the stainless steel basin 11 and welded to the stainless steel basin 11, wherein:

[0024] The stainless steel profile includes an upright wall plate 14, an inward-folding step 15 at the top of the upright wall plate 14, an upward-folding limiting edge 16 at the inner end of the inward-folding step 15, and an inward-folding top platform 17 at the top of the upward-folding limiting edge 16 , there are a plurality of steam holes 5 on the top platform 17;

[0025] The bottom of the upright wall panel 14 is provided with a bottom inner flange 13 .

[0026] The inner end of the top platform 17 is provided with a top lower flange 18, and the top lower flange 18 is welded to the top of the basin wall of the stainle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com