Electric kettle

An electric kettle and kettle body technology, which is applied to water boiling appliances and other directions, can solve the problems of broken or loose buttons on the handle, the appearance cannot be integrated, the packaging volume is increased, etc., so as to reduce the production cost and avoid the risk of collision damage. , the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

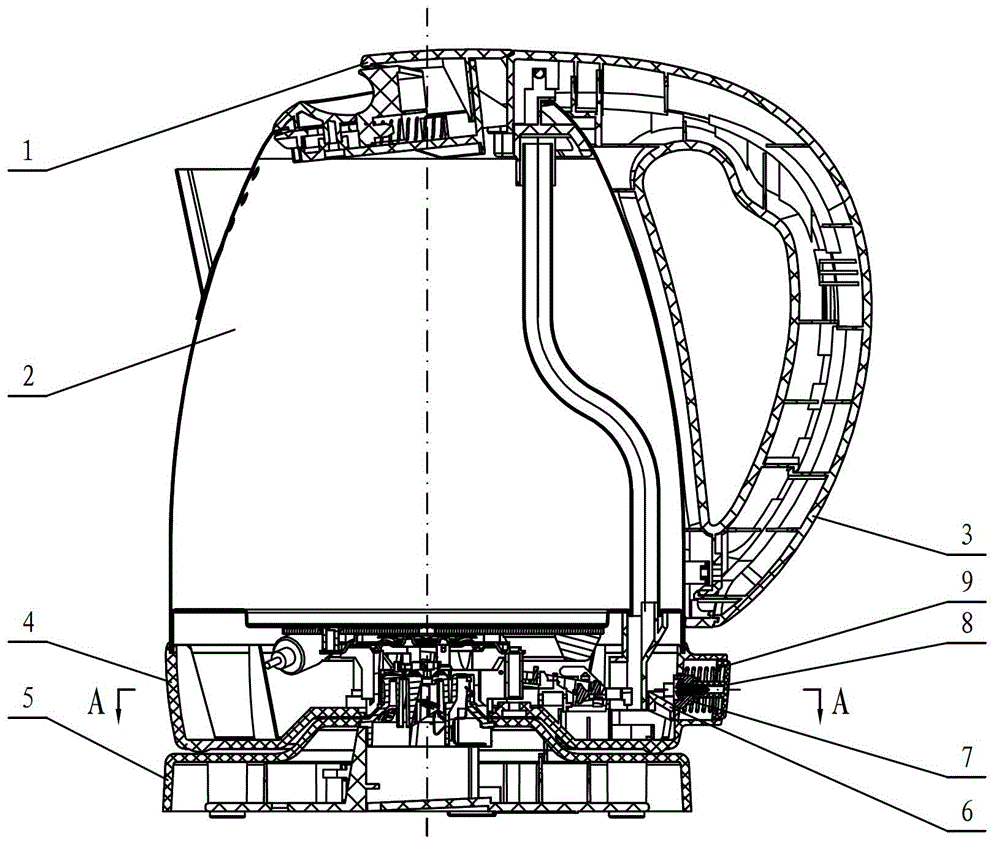

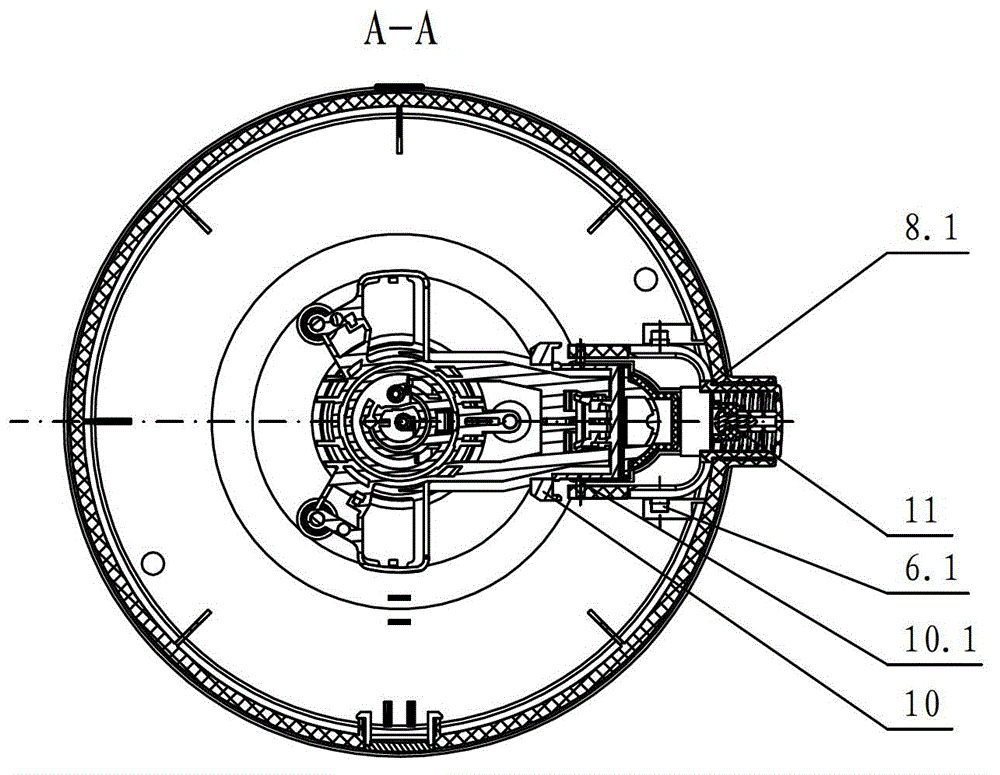

[0025] see figure 1 image 3 , the electric kettle includes a lid assembly 1 and a handle assembly 3 arranged on the body assembly 2, the body assembly 2 is connected to the power base 5 through the bottom cover 4, and the thermostat 10 and the thermostat connecting rod 6 are set In the cavity enclosed by the pot body assembly 2 and the bottom cover 4, the bottom cover 4 is provided with a button 8, the button 8 is slidably set in the bottom cover 4, and the spring 9 is crimped between the button 8 and the bottom cover 4 Between; the button 8 is connected to the connecting rod 6 of the thermostat through the pressure plate 7 . The pressing plate 7 is fixed on the button 8 with a fastener 11 . The kettle body assembly 2 is provided with a heating device. The spring 9 resets the button 8 .

[0026] The button 8 is provided with an elastic hook 8.1 for anti-off, and the elastic hook 8.1 is hooked on the bottom cover 4 . Button 8 can only be moved forward and reset by spring...

no. 2 example

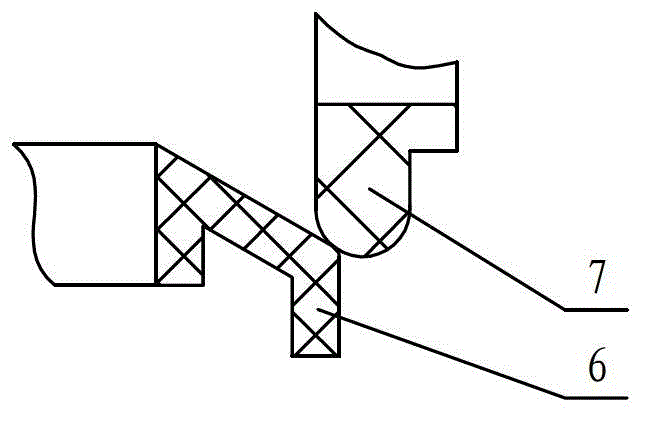

[0030] see Figure 4 , In this embodiment, a slope is provided at the position where the thermostat connecting rod 6 is in contact with the pressure plate 7 , and the slope is set on the pressure plate 7 .

[0031] When the button 8 is subjected to an external force, the button 8 moves forward in a straight line, contacts the connecting rod of the thermostat with the pressure plate 7 as an inclined plane, and moves forward. The handle 10.1 is rotated so that the thermostat 10 is powered on.

[0032] Refer to the first embodiment for the rest of the undescribed parts, and will not repeat them here.

no. 3 example

[0034] see Figure 5 , in this embodiment, the pressing plate 7 is provided with a rotating shaft 7.1, and the axis NM of the button 8 is located above the rotating shaft 7.1.

[0035] When the button 8 is subjected to an external force, the button 8 moves forward in a straight line, so that the pressure plate 7 rotates counterclockwise around the rotating shaft 7.1, and the thermostat connecting rod 6 uses the rotating shaft 6.1 as a fulcrum to make its front end drive the thermostat handle 10.1 to rotate, thereby The thermostat 10 is powered on.

[0036] Refer to the first embodiment for the rest of the undescribed parts, and will not repeat them here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com