Clamping device of aluminum absorbing pipe cleaning machine

A clamping device and a technology for sucking aluminum tubes, which are applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the damage to the support, reduce the service life of the clamping system, and reduce the work of the cleaning machine for aluminum suction tubes. Efficiency and other issues to achieve the effect of avoiding wear and facilitating sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

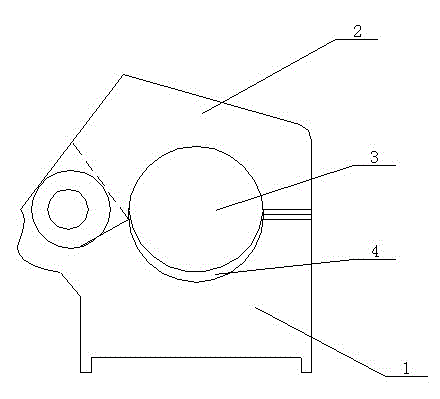

[0011] refer to figure 1 , this specific embodiment adopts the following technical solutions: it includes a support 1, a clamp cover 2 and an aluminum suction pipe hole 3, and it also includes a shock absorber 4. One end of the support 1 and the clamp cover 2 is hinged, and the support 1 and the clamp The cover 2 is closed to form the aluminum suction pipe hole 3, and the shock absorbing device 4 is arranged on the support 1.

[0012] Lubricating oil is coated on the described damping device 4 to facilitate the axial movement of the aluminum suction tube.

[0013] In this specific embodiment, the aluminum tube is clamped by closing the support 1 and the clamping cover 2, so that the cleaning machine cleans the inner wall of the aluminum suction tube, and the aluminum suction tube can move in the axial direction, which is convenient f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com