Special water-passage-containing support mechanism for ultra-high-intensity steel plate hot stamping mold

An ultra-high-strength, hot stamping technology, applied in the field of metal stamping, can solve the problems that cannot meet the requirements of new processes, and achieve the effect of accurate position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

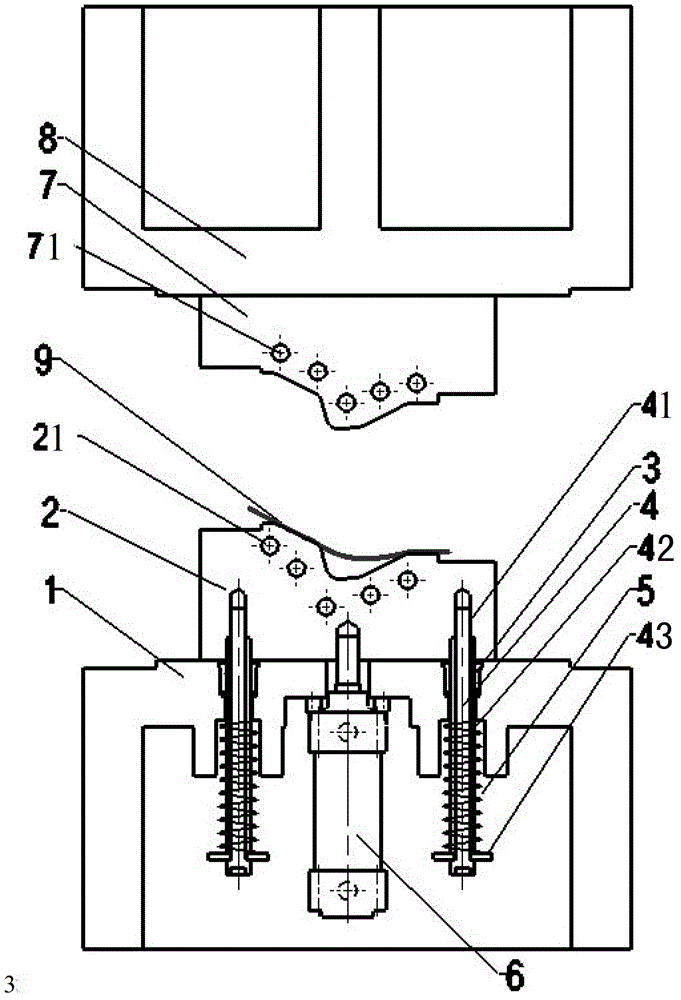

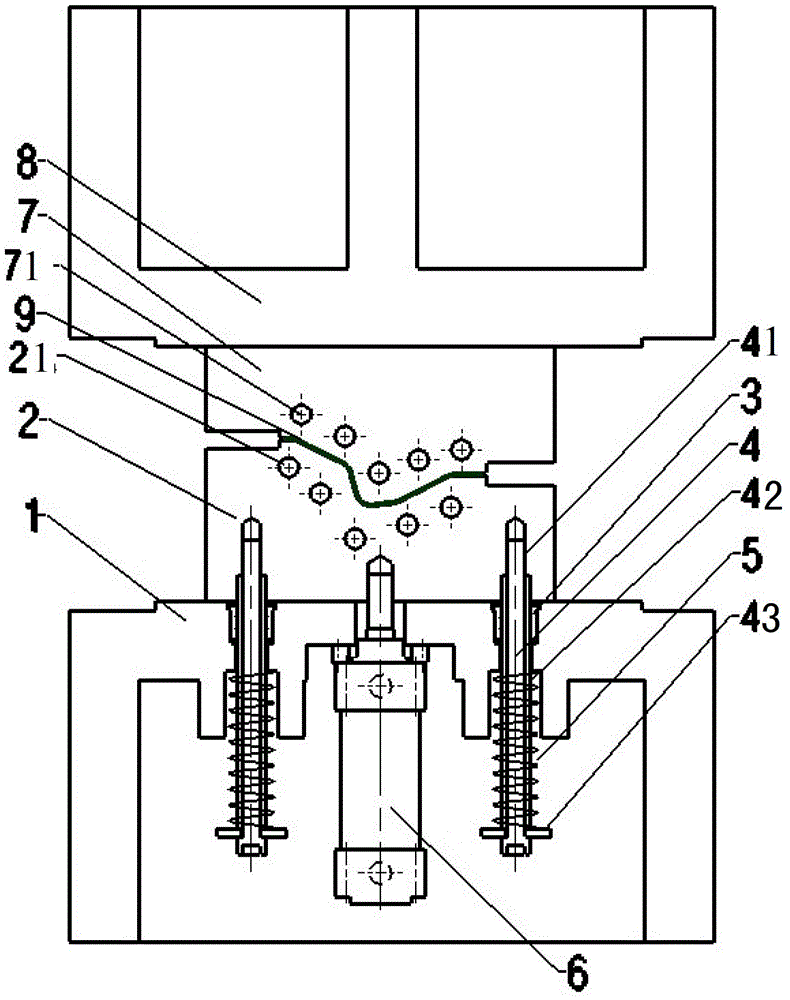

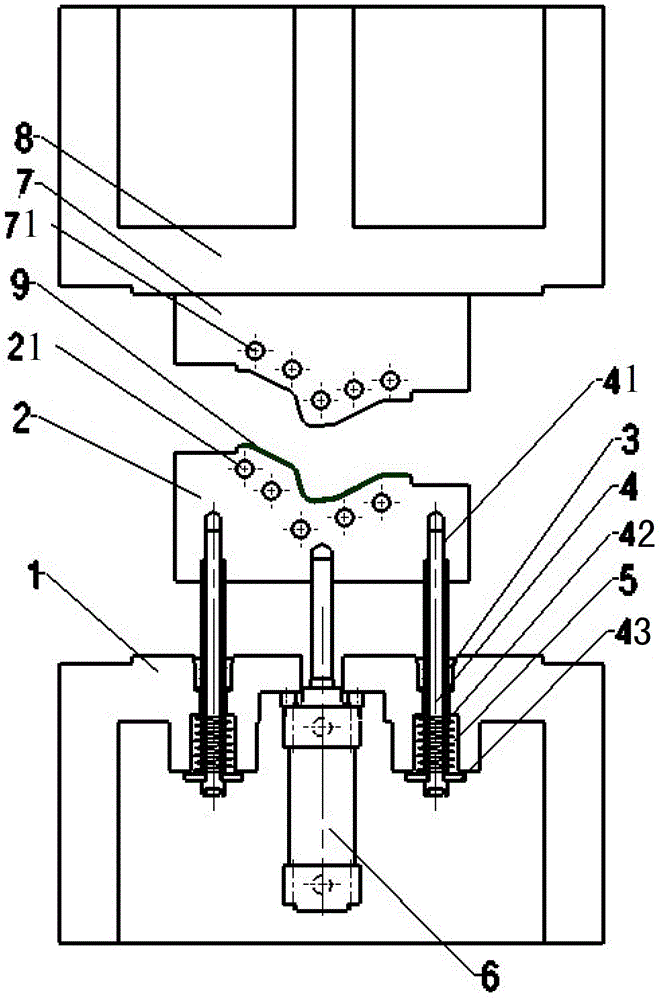

[0022] Such as figure 1 , 2 As shown, the present invention provides a support mechanism for hot stamping dies of ultra-high strength steel plates. The support mechanism for hot stamping dies of ultra-high strength steel plates includes: die body 1, support block 2, guide sleeve 3, and return screw parts 4. Spring 5, cylinder 6, upper mold insert 7, upper mold body 8, and workpiece 9; said holding block 2 has a water channel 21 on it, which is provided by a water pipe introduced outside the mold body 1 Circulating water cooling. The supporting block 2 is made of hot work die steel specially used for hot stamping. In the stamping process, the supporting block 2 participates in the forming of the workpiece; after the stamping completes the pressure holding and quenching stage, the supporting block 2 and the upper die insert 7 work together to quench the workpiece 9 under a certain pressure.

[0023] The guide sleeve 3 is installed on the mold body 1 . The wall surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com