Error-proofing mechanism of automobile welding fixture

An automobile welding fixture and error-proofing technology, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve problems such as errors, high probability of damage to lever valves, failure of error-proofing effect of lever valves, etc. The effect of small damage and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

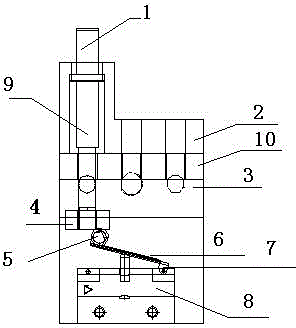

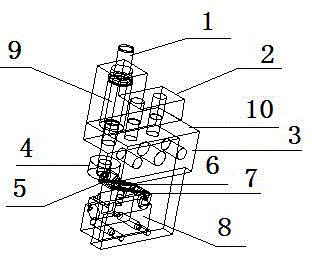

[0025] Combine below figure 1 and figure 2 , the present invention is further described:

[0026] The error prevention mechanism of the automobile welding jig of the present invention includes a positioning pin 1 , a first connecting plate 2 , a second connecting plate 3 , a lever valve 8 and a spring 9 .

[0027] Locating pin 1 is free to set and process according to the required length of the link mechanism. Assemble the Z-direction adjustment of the first connecting plate 2 and the Y-direction adjustment of the second connecting plate 3, then assemble the spring 9 and the bearing in the telescopic hole of the first connecting plate 2, and install the positioning pin 1 from the top Into the telescopic hole, the position of the lever valve 8 and the base position of the positioning pin 1 can be adjusted in the Z direction and the X direction through the connecting plate.

[0028] Compared with the anti-error mechanism of the traditional automobile welding fixture, the ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com