Automatic finishing machine tool for two planes of sealing ring

A sealing ring and precision grinding technology, which is applied to grinding machines, machine tools suitable for grinding workpiece planes, grinding/polishing equipment, etc., can solve the problems of large footprint, high cost, and heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

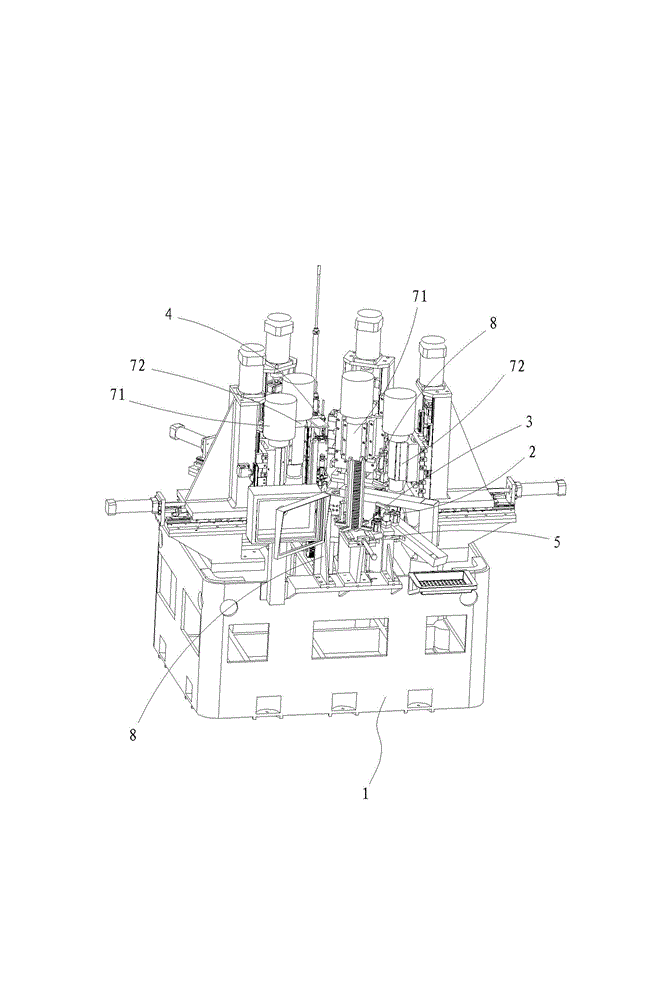

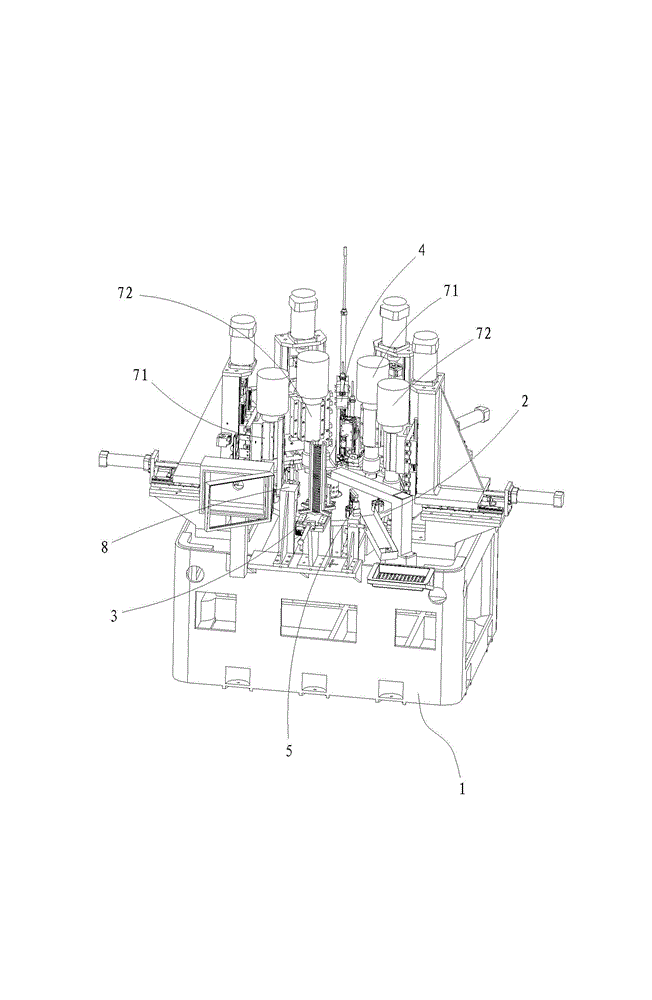

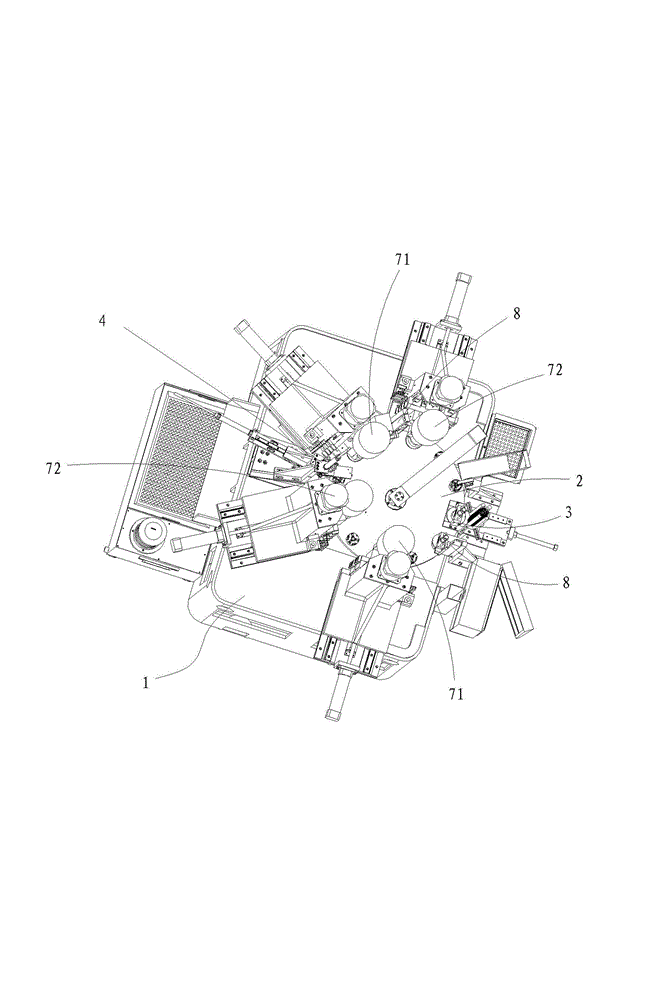

[0031] Example: see Figure 1 to Figure 12 , a double-sided automatic fine grinding machine tool for sealing rings, comprising a bed 1, a turntable 2, a feeding device 3, a grinding device, a surface changing device 4 and a discharging device 5, wherein

[0032] Bed 1, which is a structure supporting the entire grinding machine, on which a turntable 2 is installed;

[0033] The turntable 2 is provided with more than five stations along the circumferential direction, and each station is provided with a tooling 6 for fixing the sealing ring. The outer peripheral side of the turntable 2 is provided with a feeding device, a grinding device, a surface changing device, and a grinding device in turn. The device and the discharge device correspond to each station on the turntable. The sealing ring is fixed on the tooling of the first station of the turntable through the feeding device through the upper plane grinding, face changing, and lower plane grinding. Finally, it is output by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com