Anti-static caster structure, anti-static polyurethane material for producing caster and production method

A polyurethane material, anti-static technology, used in casters, wheels, transportation and packaging, etc., can solve the problems of unstable performance, low braking force, difficult to absorb, etc., to achieve good shock absorption effect, strong braking force, easy molding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1) Forming the caster rim: use aluminum alloy to form the caster rim;

[0058] 2) Mixing: Add 3kg of organic amine, 1kg of water, 20kg of dimethyl octadecyl hydroxyethyl quaternary ammonium nitrate, 10kg of white carbon black, and 10kg of boron nitride into 30kg of polyol, and stir evenly;

[0059] 3) Caster molding: mix the mixture with 26kg of isocyanate, and cast it into a mold where the caster rim is placed at 50-60°C to form a caster integrally.

[0060] The volume resistivity of the caster is 30 MΩ·cm.

Embodiment 2

[0062] 1) Forming the caster rim: use aluminum alloy to form the caster rim;

[0063] 2) Mixing: Add 3kg of organotin, 1kg of water, 20kg of polyoxyethylene ether, 8g of white carbon black, and 12g of boron nitride into 28kg of polyol, and stir evenly;

[0064] 3) Caster molding: mix the mixture with 28kg of isocyanate, and cast it into a mold where the caster rim is placed at 50-60°C to integrally form the caster.

[0065] The volume resistivity of the caster is 25 MΩ·cm.

Embodiment 3

[0067] 1) Forming the caster rim: use iron to form the caster rim;

[0068] 2) Mixing: Add 5kg of organotin, 1kg of water, 10kg of polyoxyethylene ether, 10g of white carbon black, and 15g of boron nitride into 28kg of polyol, and stir evenly;

[0069] 3) Caster molding: mix the mixture with 31kg of isocyanate, and cast it into a mold where the caster rim is placed at 50-60°C to form a caster integrally.

[0070] The volume resistivity of the caster was 22 MΩ·cm.

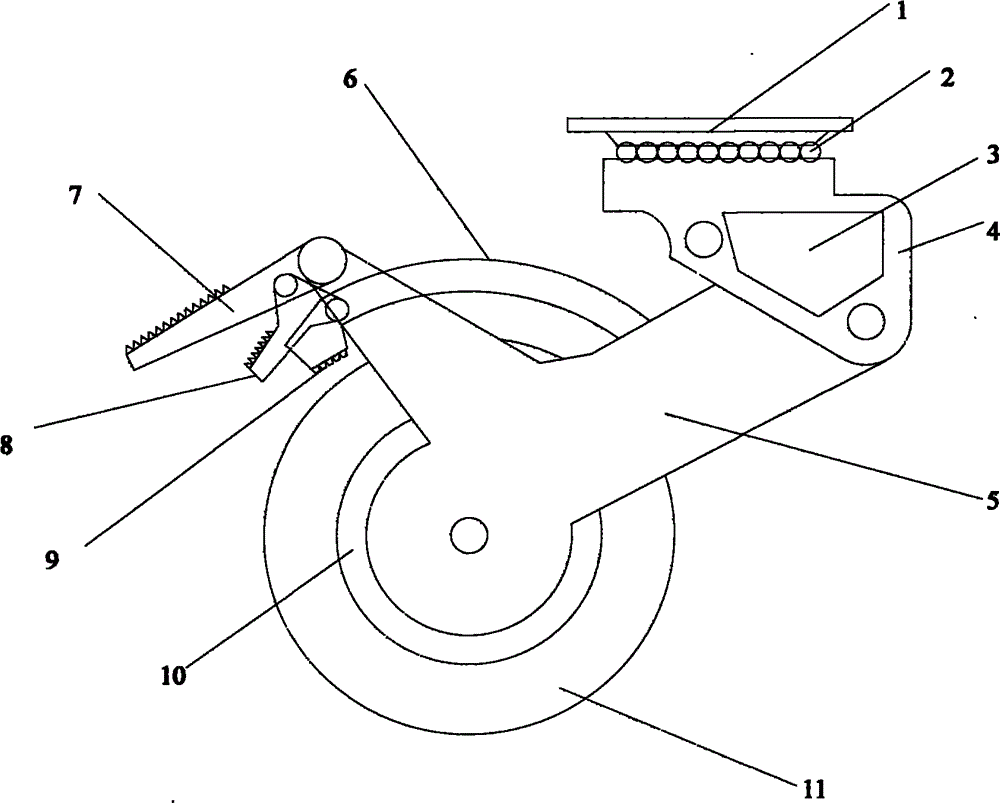

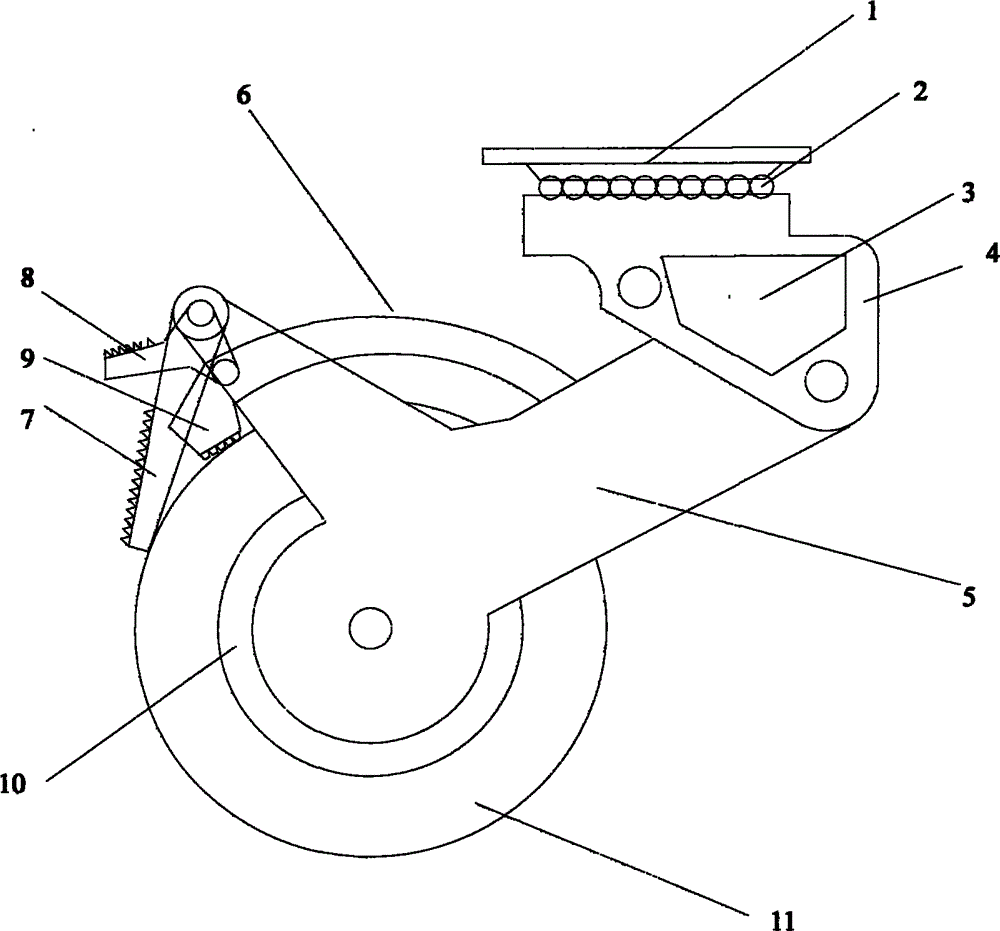

[0071] During use, the damping device 3 provides damping performance, and when braking, step on the brake plate 7 with your feet, so that the toothed part 9 of the brake lever 6 is in contact with the caster 11, so that the caster 11 is stationary; when the brake is released, step on it with your feet The brake release plate 8, the toothed portion 9 of the brake plate 6 leaves the caster 11 to make the caster 11 move.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com