Resin composition with antibacterial property and antistatic property as well as preparation method and application thereof

A resin composition, antistatic technology, applied in the field of resin composition, can solve problems such as cost increase, discoloration, antibacterial agent stability increase, etc., to prevent adsorption of dust and other substances, good durability and weather resistance, and prevent bacteria Effect of infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The preparation method of the resin composition with antibacterial activity and antistatic performance of the present invention, comprises the following steps: (1) general-purpose resin and dendrimers used as base resin, with the weight ratio of general-purpose resin and dendrimers as 90-99: 10-1 Mixing and extruding to obtain composite resin; (2) Mixing antibacterial agent and antistatic agent in the composite resin obtained in step (1), and the total weight of antibacterial agent and resin composition The percentage by weight is 0.01-10%, and the percentage by weight of the total weight of the antistatic agent and the resin composition is 5-25%, so as to obtain a resin composition with antibacterial activity and antistatic performance.

[0056] Step (1) The general-purpose resin used as the base resin is mixed and extruded to obtain a composite resin. The mixing temperature, mixing time and extrusion temperature are based on the type and use of the dendritic polymer re...

Embodiment 1

[0061] (1) Mixing and extruding 2 parts by weight of dendritic polymers and 98 parts by weight of polypropylene to obtain a composite resin. Dendritic polymers are prepared according to the method described in the patent KR100852384, mixing and The extrusion time is kept for 6-10 hours, the kneading temperature is kept at 80-100°C, and the extrusion temperature is kept at 180-220°C.

[0062] (2) Add colloidal silver (product name of Korea Co., Ltd. Semo Co., Ltd.: Semo Colloidal Silver) to the composite resin in the amount shown in Table 1, and metal copper particles ( Average particle diameter 10nm) / metal silver particles (average vertical diameter 5nm) / graphene / single-walled carbon nanotubes (weight ratio 10 / 0.1 / 0.1 / 0.1) mixture is added and mixed to obtain a resin composition, wherein, Table 1 The content shown in is the percentage by weight of antibacterial agent colloidal silver in the resin composition; The percentage by weight of antistatic agent in the resin compositio...

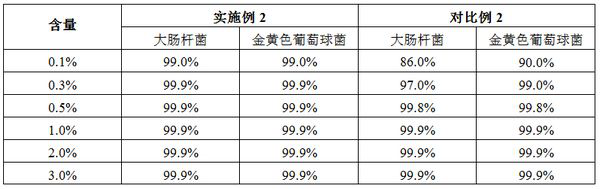

Embodiment 2

[0072] (1) Mix 2 parts by weight of dendrimers and 98 parts by weight of polyethylene terephthalate to obtain a composite resin. The dendrimers are prepared according to the method described in the patent KR100852384. The time of kneading and extruding is kept for 6-10 hours, the kneading temperature is kept at 80-100°C, and the extrusion temperature is kept at 180-220°C.

[0073] (2) Add colloidal silver (product name of Korea Co., Ltd. Semo Co., Ltd.: Semo Colloidal Silver) to the composite resin in the amount shown in Table 2, and metal copper particles ( Average particle diameter 10nm) / metal silver particles (average vertical diameter 5nm) / graphene / single-walled carbon nanotubes (weight ratio 10 / 0.1 / 0.1 / 0.1) mixture is added and mixed to obtain a resin composition, wherein, Table 1 The content shown in is the percentage by weight of the antibacterial agent colloidal silver in the resin composition, and the percentage by weight of the antistatic agent in the resin compositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com