Permanent antistatic flexible polyethylene pipe special material

A polyethylene pipe, antistatic technology, applied in the field of composite materials, can solve the problems of loss of antistatic ability, constant impact strength, and decreased conductivity, and achieve good environmental adaptability, lower modulus, and good thermal creep resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

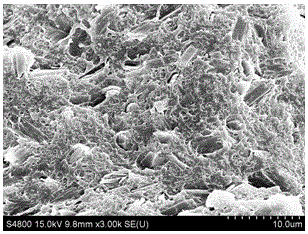

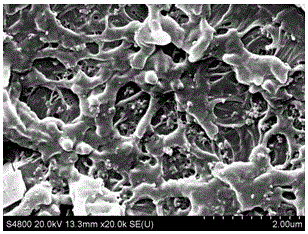

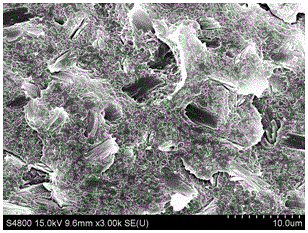

Image

Examples

Embodiment 1

[0032] Example 1, a permanent antistatic flexible polyethylene pipe special material, the weight parts of each component are: 100 parts of medium density polyethylene PE-RT, 25 parts of EVA carrier conductive carbon black masterbatch, thermoplastic elasticity Body POE 5.5 parts, dispersant EBS 1.5 parts, antioxidant 1010 0.2 parts, antioxidant 168 0.2 parts, mold release agent zinc stearate 0.2 parts, liquid paraffin 0.2 parts.

[0033] Medium-density polyethylene PE-RT base material adopts melt index MFR=0.6-0.8g / 10min, test pressure load 2.16kg, temperature 195℃.

[0034] Melt index is a parameter to measure the fluidity of a polymer. It is denoted as MFR, which is defined as the polymer weight of a thermoplastic resin that passes through a standard pore within 10 minutes under a specified temperature and pressure load. The unit is g / 10min.

[0035] The preparation method includes the following steps:

[0036] 1) Dry 1.5Kg medium-density polyethylene PE-RT base material, 0.375Kg EVA...

Embodiment 2

[0042] Example 2, a permanent antistatic flexible polyethylene pipe special material, the weight of each component is: 100 parts of medium density polyethylene PE-RT, 30 parts of EVA carrier conductive carbon black masterbatch, thermoplastic elasticity Body POE-g-MAH 3 parts, dispersant EBS 1.5 parts, antioxidant 1010 0.2 parts, antioxidant 168 0.2 parts, mold release agent zinc stearate 0.2 parts, methyl silicone oil 0.2 parts.

[0043] Medium-density polyethylene PE-RT base material adopts melt index MFR=0.6-0.8g / 10min, test pressure load 2.16kg, temperature 195℃.

[0044] Melt index is a parameter to measure the fluidity of a polymer. It is denoted as MFR, which is defined as the polymer weight of a thermoplastic resin that passes through a standard pore within 10 minutes under a specified temperature and pressure load. The unit is g / 10min.

[0045] The preparation method includes the following steps:

[0046] 1) Dry 1.5Kg medium density polyethylene PE-RT base material, 0.45Kg EVA...

Embodiment 3

[0052] Example 3, a special material for permanent antistatic flexible polyethylene pipe, the weight parts of each component are respectively: 100 parts of medium density polyethylene PE-RT, 30 parts of LLDPE carrier conductive carbon black masterbatch, thermoplastic elasticity Body POE 4 parts, dispersant EBS 1.5 parts, antioxidant 1010 0.2 parts, antioxidant 168 0.2 parts, release agent zinc stearate 0.2 parts, liquid paraffin 0.2 parts.

[0053] Medium-density polyethylene PE-RT base material adopts melt index MFR=0.6-0.8g / 10min, test pressure load 2.16kg, temperature 195℃.

[0054] Melt index is a parameter to measure the fluidity of a polymer. It is denoted as MFR, which is defined as the polymer weight of a thermoplastic resin that passes through a standard pore within 10 minutes under a specified temperature and pressure load. The unit is g / 10min.

[0055] The preparation method includes the following steps:

[0056] 1) Dry 1.5Kg medium density polyethylene PE-RT base material,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com