Incompatible failure safety analysis system and method for air plane motor

An aircraft engine, non-inclusive technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low analysis and evaluation efficiency, omission of multiple system combinations, difficulty in analysis and evaluation, and heavy workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

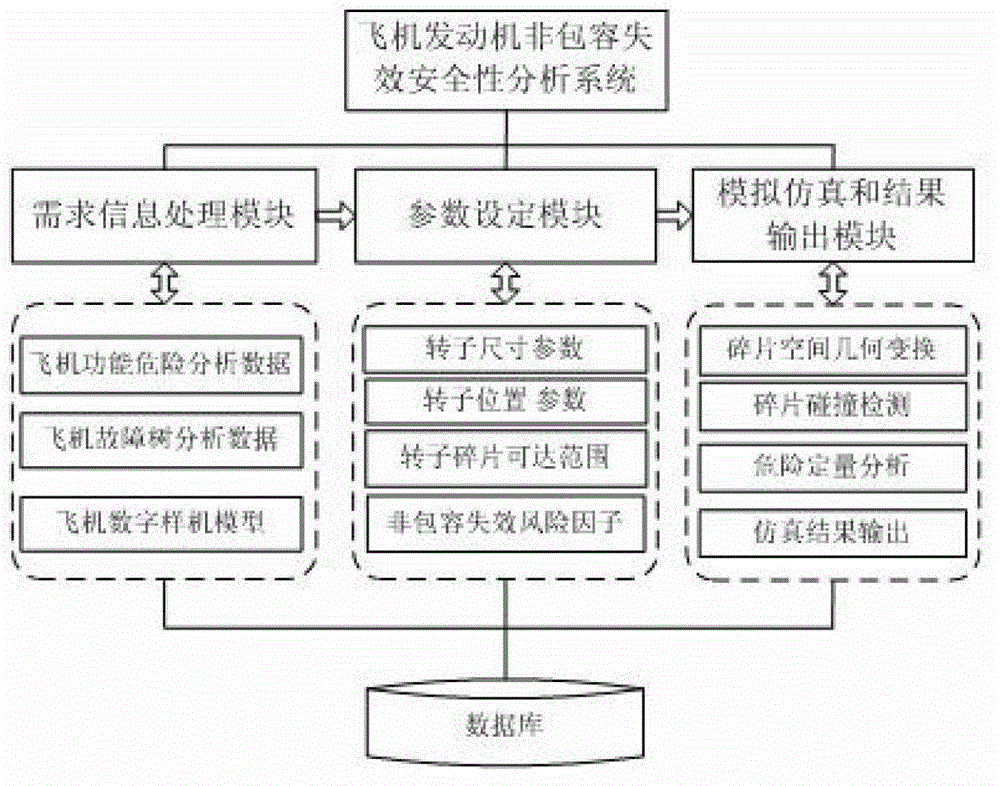

[0038] like figure 1 The aircraft engine non-containment failure safety analysis system shown includes a demand information processing module, a parameter setting module, a simulation and result output module, and the demand information processing module, parameter setting module, simulation and result output module are all connected with the database interact.

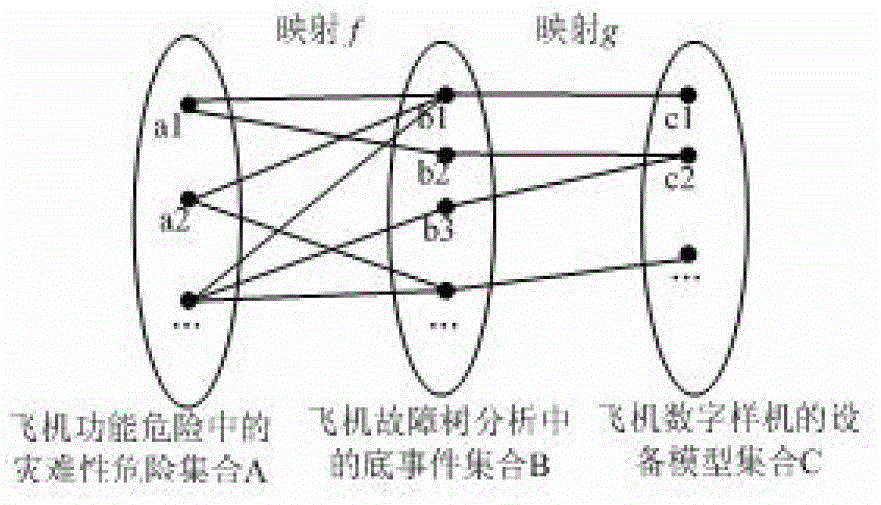

[0039] The demand information processing module is used to import aircraft digital prototype model, catastrophic functional risk analysis data, and fault tree analysis data. like figure 2 As shown, the mapping relationship f from catastrophic functional hazard analysis (FHA) data to fault tree analysis (FTA) data, and the mapping relationship g from fault tree analysis data to aircraft digital prototype equipment model are established. Catastrophic hazard set A in aircraft functional hazards includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com