XY precision motion platform capable of suppressing vibration by utilizing piezoelectric ceramic

A technology of precision motion, piezoelectric ceramics, applied in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of easy vibration, low system stiffness, etc., to improve the stiffness of the mechanism, the overall structure is simple, and the size of the structure small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in conjunction with accompanying drawing:

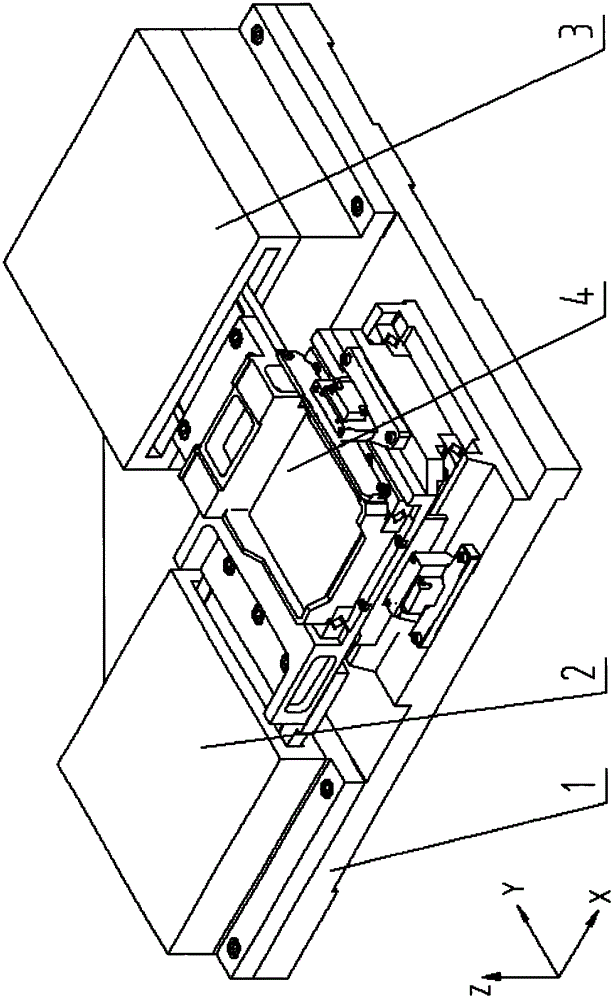

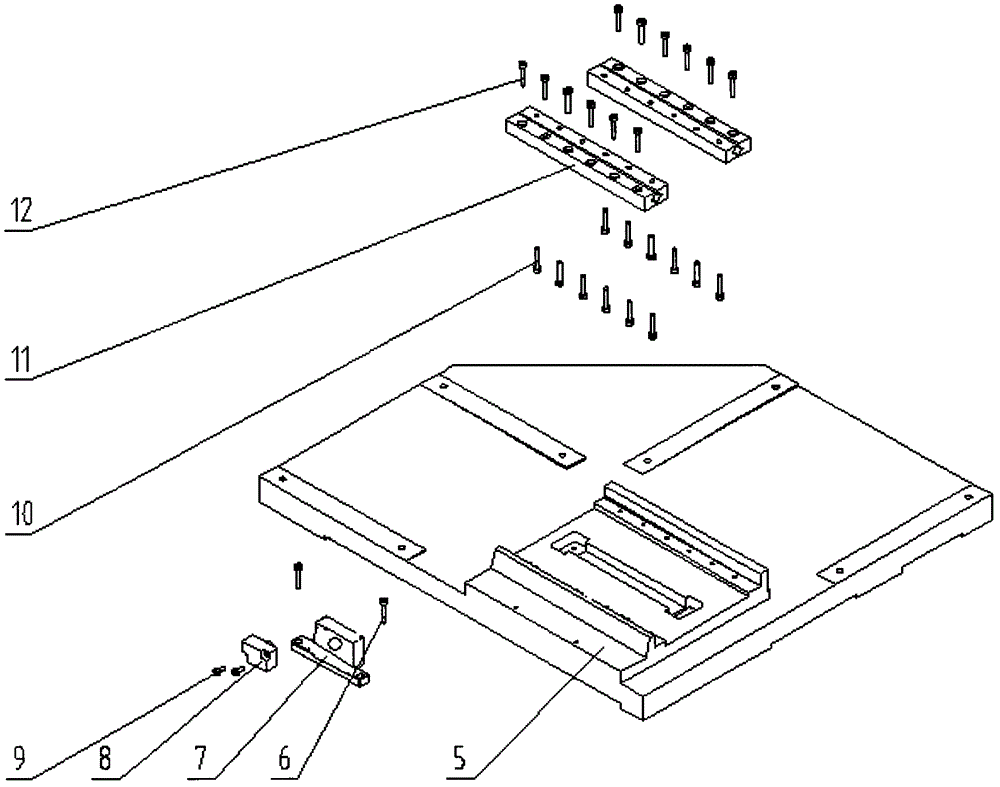

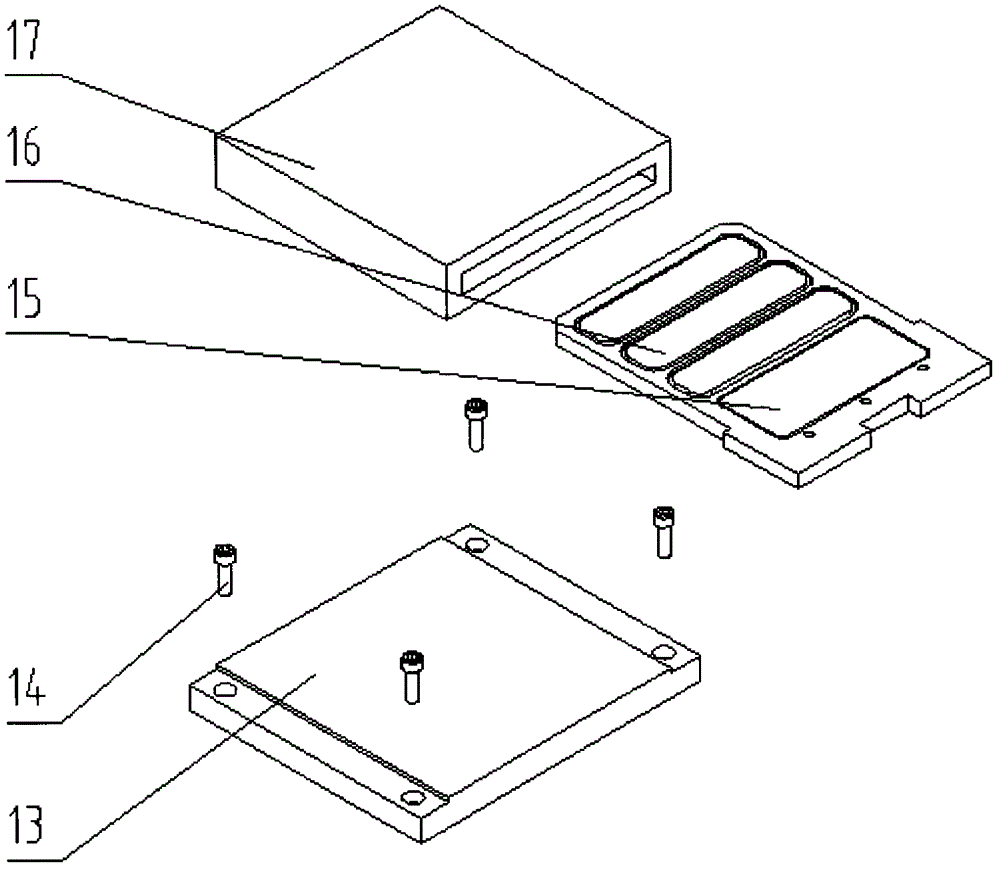

[0036] Referring to the accompanying drawings, the XY precision motion platform for piezoelectric ceramic vibration suppression of the present invention includes: a base plate assembly 1, an X-axis linear motor assembly 2, a Y-axis linear motor assembly 3, a motion connector assembly 4, a base plate 5, and an X-axis Angle frame mounting screw for grating ruler reading head 6, angle frame for X-axis grating ruler reading head 7, X-axis grating ruler reading head 8, mounting screw for X-axis grating ruler reading head 9, X-axis precision motion rail fixing rail mounting screw 10, X-axis precision Motion guide rail 11, X-axis precision motion guide rail sliding rail mounting screw 12, X-axis linear motor mounting seat 13, X-axis linear motor mounting seat screw 14, X-axis mover piezoelectric ceramic film 15, X-axis linear motor mover assembly 16 , X-axis linear motor stator and hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com