Multifunctional automatic dumpling machine

A fully automatic, dumpling machine technology, applied in baking, food preparation, dough processing, etc., can solve the problems of inability to achieve synchronization, inaccurate quantification, poor quality of dumplings, etc., to reduce cumbersome procedures, consistent shape and size, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

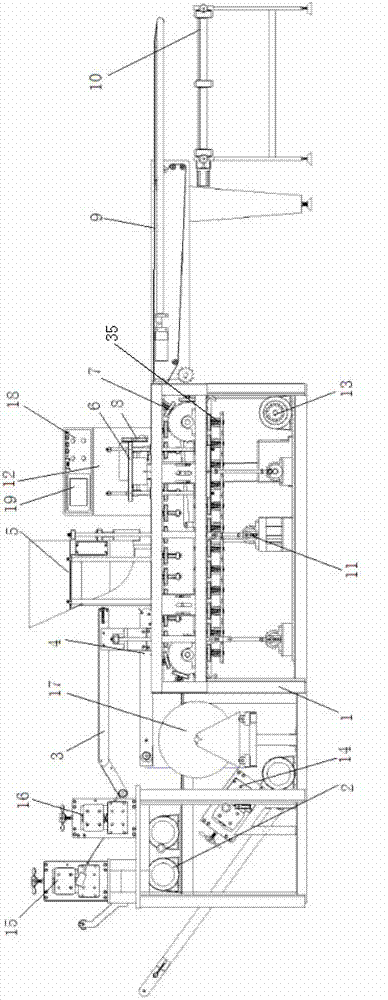

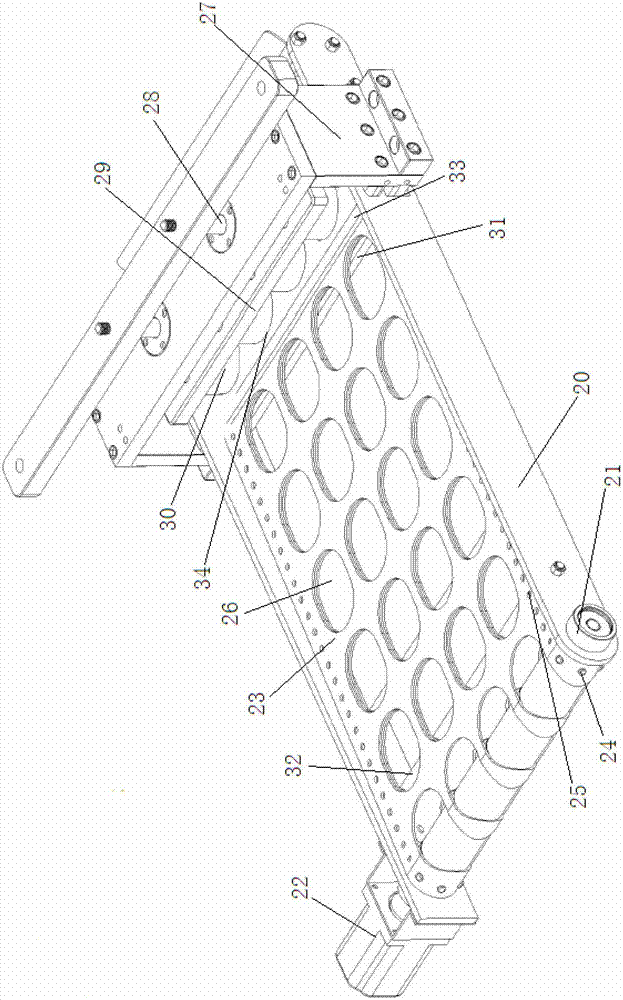

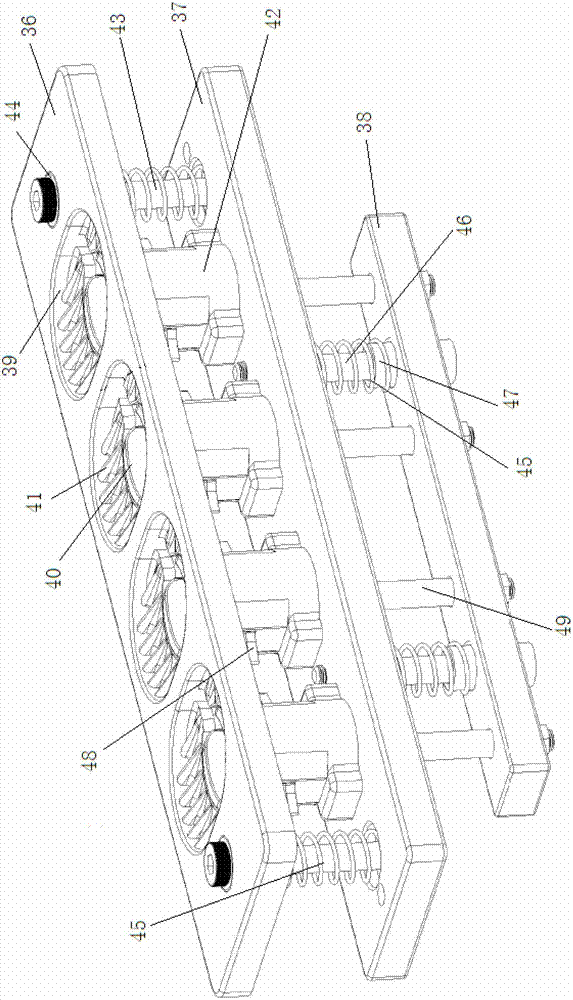

[0026] Such as Figure 1 to Figure 9As shown, a multi-functional automatic dumpling machine includes a frame 1, a rolling mechanism 2, a dough conveyor belt 3, a punching conveyor mechanism 4, a stuffing device 5, a mold clamping device 6, and a wraparound intermittent rotating dumpling forming machine. Template 7, dumpling propeller 8, pan delivery mechanism 9, pan mechanism 10, intermittent driving device 11, electrical control box 12 and stepper motor 13, the left end of the frame 1 is provided with a rolling mechanism 2, and the rolling Leather mechanism 2 comprises one, two, three-stage pressing rollers 14,15,16, and three-stage pressing roller 16 front ends are provided with dough conveyer belt 3, described dough conveyer belt 3 is provided with punching leather conveying mechanism 4, described The bottom left of the end of the skin punching conveying mechanism 4 is provided with a dough winding frame 17, the front end of the skin punching conveying mechanism 4 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com