Knee arthroscopic meniscal stitching needle

A technique for suturing needles and meniscus, applied to trocars and other directions, can solve the problems of blunt needles, fixed sutures, laborious puncture, etc., and achieves the effect of overcoming the difficulty of threading, preventing the leads from falling off, and facilitating surgical operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

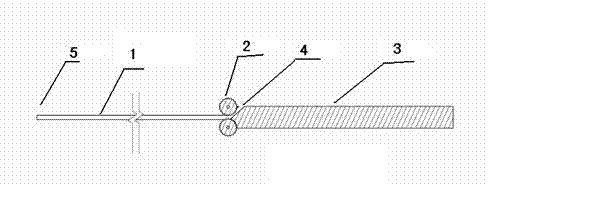

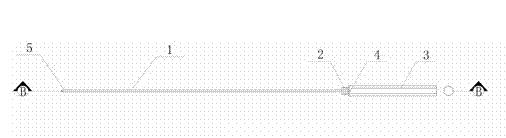

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] The invention provides a meniscus suture needle for knee arthroscopy, which comprises a hollow needle body, a pulley, a handle, a thread inlet hole and a needle point. The distal end of the needle body is a needle tip, which is sharp and has an oblique opening, which is beneficial to the puncture of soft tissues, joint capsules and menisci. The needle body is a hollow medical stainless steel structure with a diameter of about 1.5 mm and a length of about 6-8 cm. Curved, right-curved and upturned in various directions to meet the needs of clinical applications. The rear of the needle body is connected with the handle and the pulley. The pulley is located in front of the handle. There is a wire inlet hole behind the pulley. The lead wire can be passed in or out. After the lead wire is passed through the wire inlet hole, the pulley is turned, and the lead wire pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com