Post-processing modification method of Ti-Si molecular sieve

A titanium-silicon molecular sieve, molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of difficulty in significantly improving the catalytic activity of TS-1, inability to modify, etc., and achieve simple and easy operation. It is easy to operate, the process is easy, and the catalytic oxidation activity is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

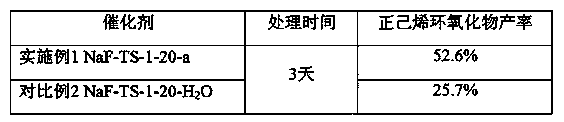

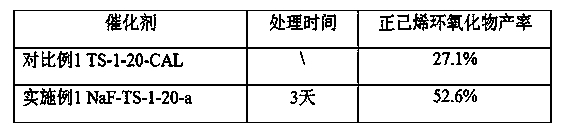

[0034] (1) Grind TS-1-20-CAL synthesized in Comparative Example 1 with sodium fluoride evenly, SiO 2 The molar ratio of / NaF was 50. The dry glue obtained is transferred to the lining of a small crystallization kettle.

[0035] (2) First add a certain amount of deionized water and small supports to the bottom of the inner substrate of the large crystallization kettle. The weight ratio of deionized water to dry glue is 1:1, and place the dry glue prepared in step (1) The small liner is placed on the support in the large crystallization tank so that the small liner where the dry glue is placed is not in direct contact with the water phase. Finally, the crystallization tank is closed and allowed to stand at 175°C for 3 days. The sample is routinely filtered, washed, and dried to obtain a modified titanium-silicon molecular sieve NaF-TS-1-20-a.

Embodiment 2

[0037] (1) Grind the TS-1-50-CAL synthesized in Comparative Example 1 with sodium fluoride evenly, SiO 2 The molar ratio of NaF / NaF was 50 and milled for 30 minutes. The prepared dry glue is evenly divided into three parts and transferred to three small crystallization kettle linings respectively.

[0038] (2) Except for the following differences, the operation steps are the same as step (2) of Example 1. The three dry glues were left standing at 175°C for 1, 3, and 7 days respectively. Modified titanium-silicon molecular sieves NaF-TS-1-50-a, NaF-TS-1-50-b, and NaF-TS-1-50-c were obtained respectively.

Embodiment 3

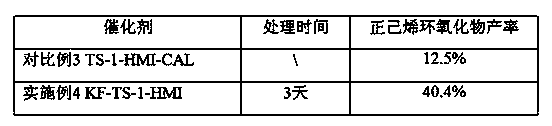

[0045] (1) Grind the TS-1-HMI-CAL synthesized in Comparative Example 3 with sodium fluoride evenly, SiO 2 The molar ratio of / NaF was 25. The dry glue produced is transferred to the lining of a small crystallization kettle.

[0046] (2) The operation steps are the same as step (2) of Example 1. A modified titanium-silicon molecular sieve NaF-TS-1-HMI was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com