Practical device for replacing cooling liquid after welding

A practical device and cooling liquid technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inconvenience, automatic welding influence, high cost of refrigeration equipment, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

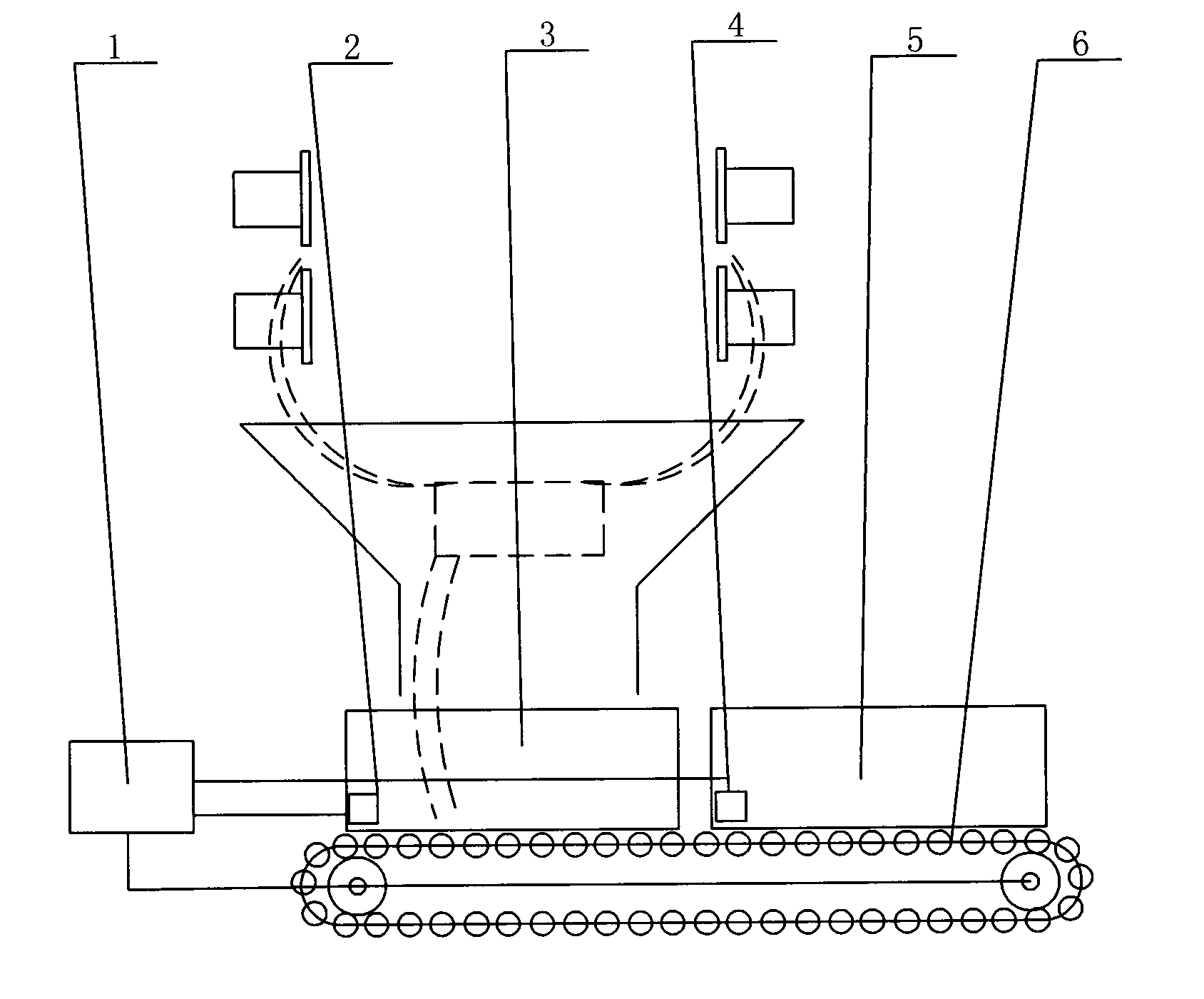

[0007] see figure 1 , the specific embodiment adopts the following technical scheme: it includes a motor 1, a temperature sensor 2, a first coolant tank 3, a second coolant tank 5 and a circulation replacement track 6; the circulation replacement track 6 is provided with a first coolant The tank 3 and the second coolant tank 5, the first coolant tank 3 and the second coolant tank 5 are respectively provided with a temperature sensor 2, and the temperature sensor 2 and the circulation replacement track 6 are connected to the motor 1 at the same time.

[0008] When the temperature sensor 2 detects that the temperature of the coolant tank is too high, the motor 1 is automatically started, and the motor 1 drives the circulation replacement track 6 to operate, and the positions of the first coolant tank 3 and the second coolant tank 5 are replaced.

[0009] The specific embodiment has a simple structure, and the cooling liquid tank is automatically replaced when the temperature of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap