Automatic slitter positioning system of high-speed intelligent dividing and cutting machine

An intelligent, slitting machine technology, applied in the direction of metal processing, etc., can solve the problems of cumbersome operation of knife arrangement, lower production efficiency, and inability to guarantee knife arrangement, so as to facilitate diagnosis and elimination, improve production efficiency, and improve the accuracy of knife arrangement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

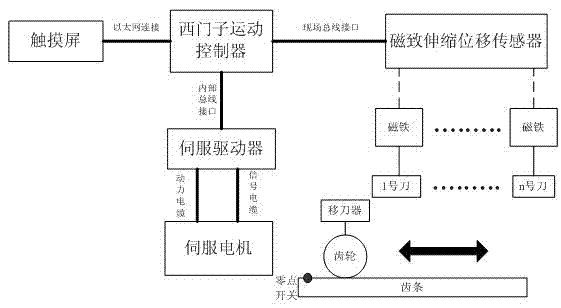

[0025] The system of the invention includes a closed-loop control system composed of a Siemens motion controller, a servo motor, a magnetostrictive position sensor, a touch screen and a servo driver. like figure 1 As shown, the magnetostrictive position sensor is connected to the field bus interface of the Siemens motion controller, the touch screen and the Siemens motion controller communicate through an Ethernet connection, and the Siemens motion controller is connected to the servo driver through an internal bus interface based on Ethernet technology , the servo drive is connected to the servo motor by a power cable and a signal cable. The shaft end of the servo motor is connected to a gear for walking on the rack. At the same time, the base of the servo motor is connected to a knife mover. The cylinder is used to move each razor holder. The terminal of the rack is equipped with a zero point switch, which is used to unify the coordinates of the servo system with the coordi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap