Molding method for powder tablet and device thereof

A molding method and powder tableting technology, which is applied in the direction of material molding presses, presses, manufacturing tools, etc., can solve the problems of poor thickness uniformity, easy breakage of tablets, etc., and achieve uniform distribution of powder particle density and high safety , highly consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

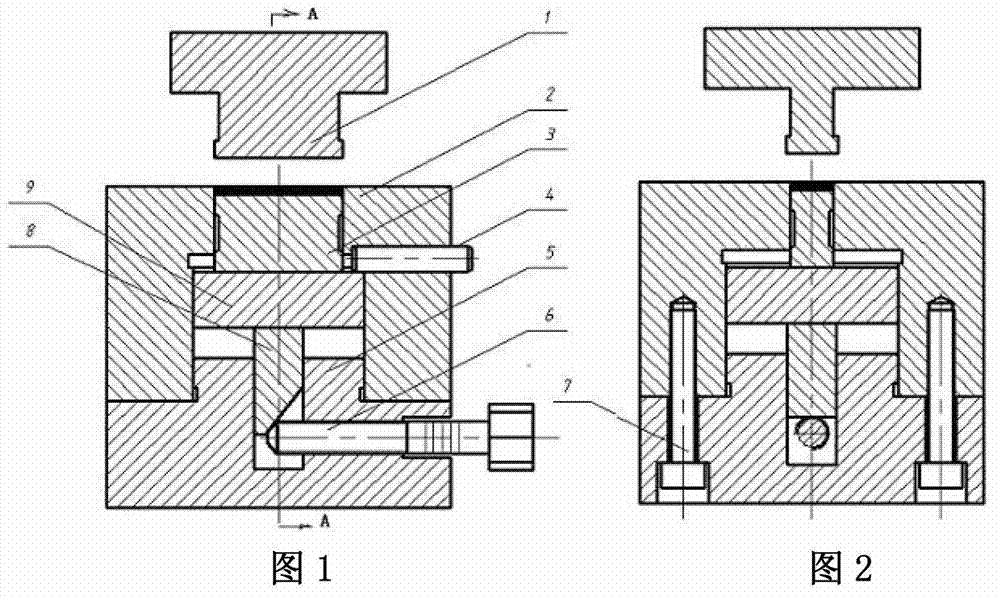

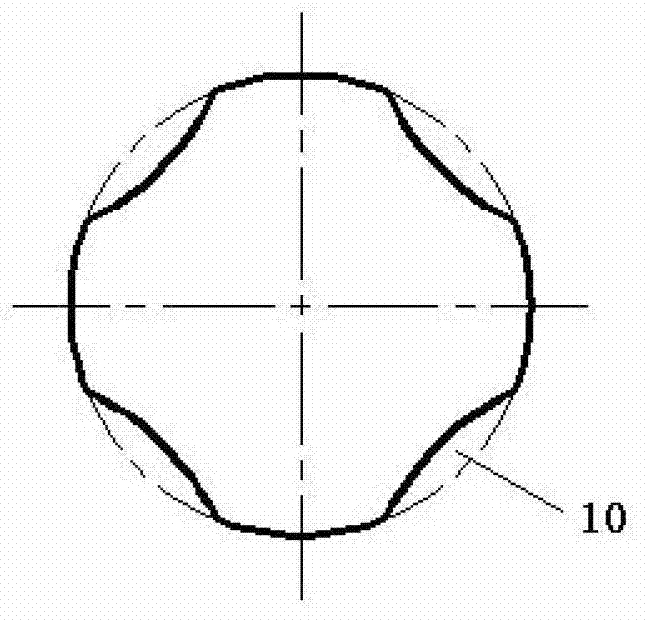

[0034] Such as Figure 1-3 shown.

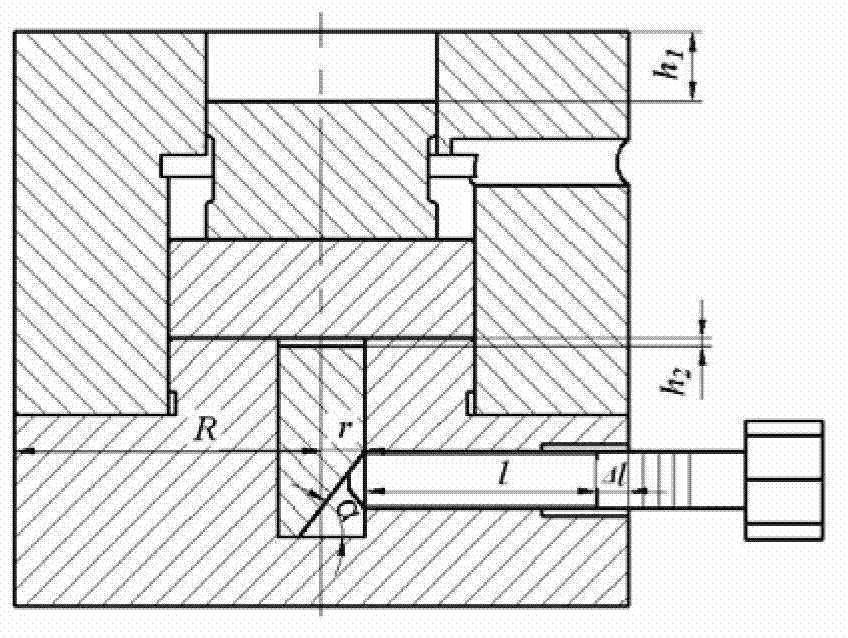

[0035] A tablet pressing mold, which is mainly composed of a molding head 1, a mold barrel 2, a mold core 3, a positioning pin 4, a mold base 5, an adjusting screw 6, a connecting screw 7, a slider 8 and a mold core base 9, such as figure 1 As shown, the mold barrel 2 is connected with the mold base 5 through the connecting screw 7, as figure 2 As shown, the mold core 3 and the mold core base 9 are installed in the guide hole in the mold cylinder 2, the slider 8 is movably fitted in the mold base 5, its upper flat end is offset against the mold core base 9, and the lower part of the slider 8 The slope at the inclined end is offset against the end of the adjusting screw 6 , which is screwed in the mold base 5 , and the axis of the adjusting screw 6 is perpendicular to the axis of the slider 8 . The locating pin 4 that controls the rising height of the mold core base 9 is installed on the mold barrel 2, and a boss is provided in the mountin...

Embodiment 2

[0040] Such as Figure 5 shown.

[0041] A molding method for powder compression, which comprises the following steps:

[0042] First, adjust the tableting die (such as figure 1 As shown), the adjusting screw 7 on the core base 9 moves upward until the upper surface of the core 3 installed on the core base 9 reaches the scale line corresponding to the height of the required initial powder loading; in specific implementation, in order to control the mold The height of the rise of the core base 9 can be installed on the mold barrel 2 with a positioning scale 4, and the axes of the positioning pin 4 and the adjusting screw 6 are all perpendicular to the axis line of the slider;

[0043] Secondly, the powder is packed in the mold cylinder 2, so that the upper surface of the powder exceeds the upper surface of the mold cylinder 2;

[0044] The third, scrape off the powder beyond the upper surface of the mold barrel 2 with a scribe until the upper surface of the powder is flush w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com