Magnetic yoke assembly

A yoke and assembly technology, applied in power transmission devices, printing, transfer materials, etc., can solve the problems of unclear printing effect of printers, restricting the market position of domestic yokes, and poor magnetic conduction effect, etc., to achieve clear printing effect , Good magnetic conduction effect, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

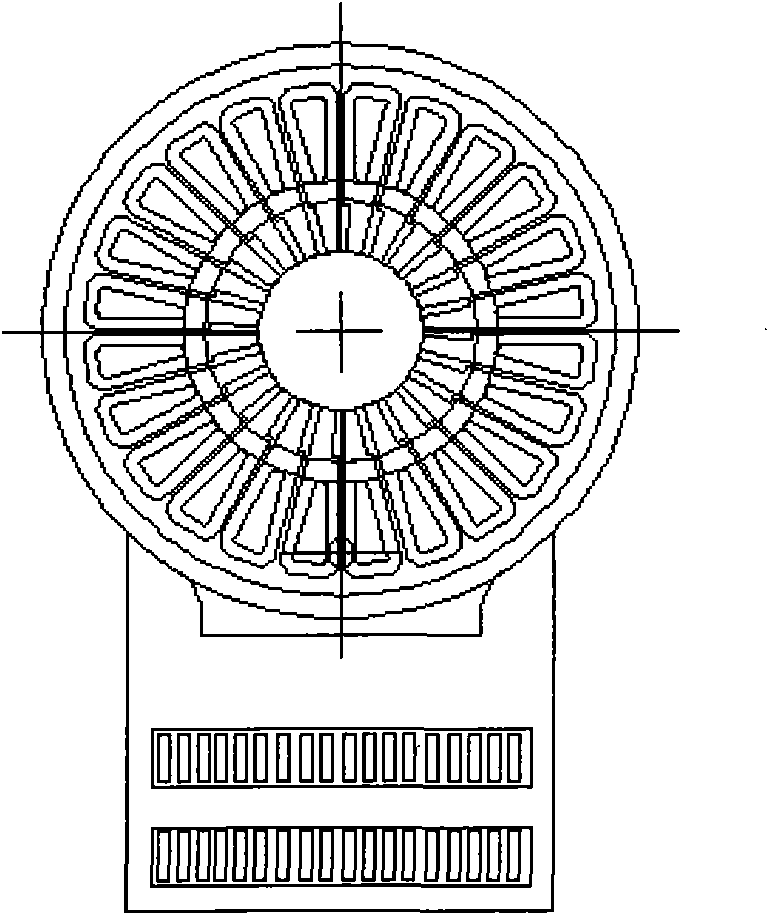

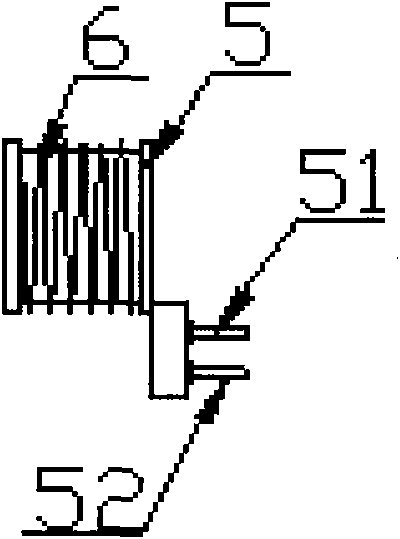

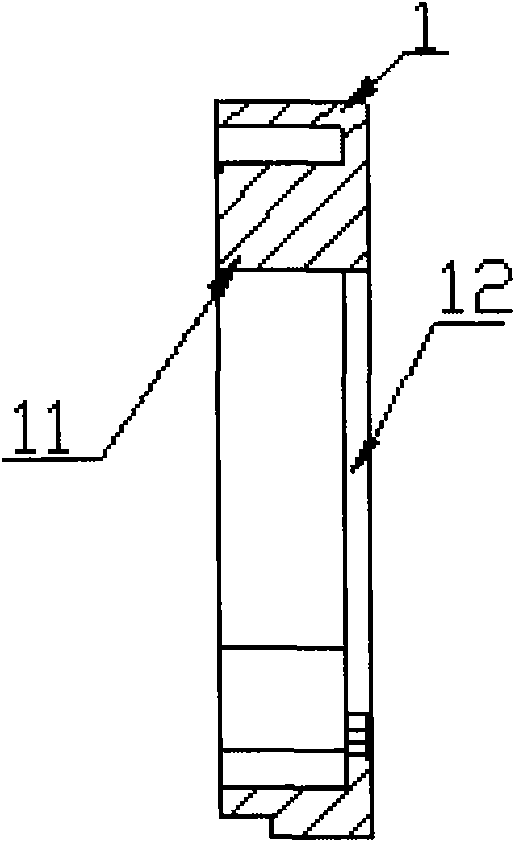

[0012] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention relates to a magnetic yoke assembly, including a magnetic yoke 1, a triangular tooth 11, a coil 6, a plastic sleeve 5, copper wire inserts 51 and 52, a circuit board 2, plugs 3 and 4, and the interior of the magnetic yoke 1 There are several triangular teeth 11, whose function is to form a complete magnetic field line circuit on the yoke 1 after the coil 6 is energized, and the coil winding 6 is wound on the plastic sleeve 5, and the plastic sleeve 5 is set on each triangular tooth 11 and fixed, the two ends of the winding of the coil 6 are respectively connected with two copper wire inserts 51 and 52, and the copper wire inserts 51 and 52 are welded on the circuit board 2 through the round hole 12, and the circuit board 2 is provided with a plug 3 And 4 and circular hole 21.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com