Coal bunker capable of preventing chute blockage and coal agglomeration

A technology to prevent coal blockage and coal bunker, applied in containers, packaging, transportation and packaging, etc., can solve problems such as hidden dangers of personal safety, unstable coal supply, and inability to meet the load requirements of dispatching, so as to eliminate the occurrence of vicious accidents, Improve efficiency and safety, eliminate the effect of coal blocking and shed coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

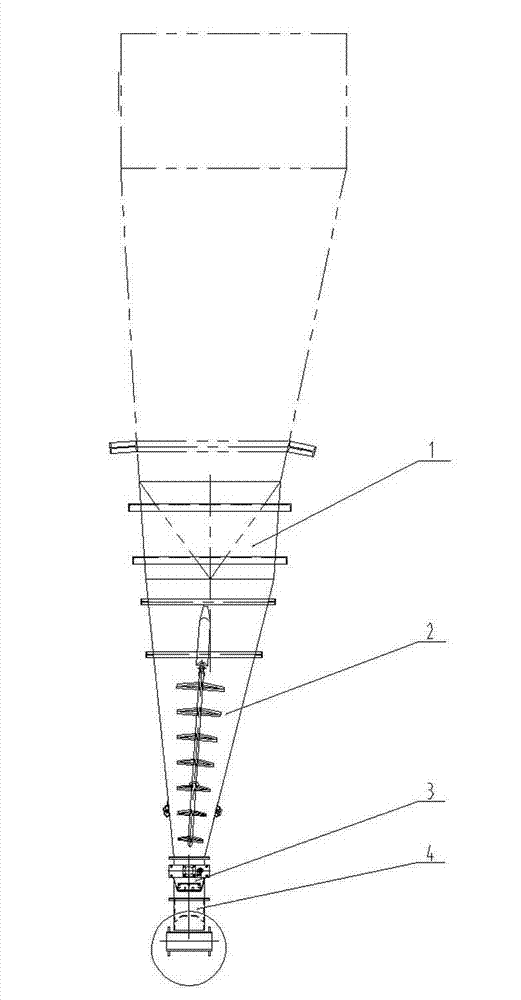

[0012] see figure 1 , the present invention includes a coal bunker 1, a loosening machine 2, and a hydraulic cut-off door 3. The coal bunker 1 is conical, and a looser 2 is arranged in the lower vertebral part of the coal bunker 1, and a hydraulic cut-off door is set at the coal outlet of the coal bunker 1. The door 3, the lower part of the hydraulic cut-off door 3 is connected with the coal feeder through the inlet nipple 4; the hydraulic cut-off door 3 is connected with a controller.

[0013] The angle between the bunker wall and the horizontal plane of the above-mentioned coal bunker 1 is greater than or equal to 73 degrees, and all of them are arc-curved surfaces, which well solves the problem of coal accumulation at the corners of the rectangular coal bunker.

[0014] The inner wall of the above coal bunker 1 is provided with a liner, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com