Container handling machine and machine for container handling

A container processing machine and container technology, applied in liquid processing, conveyors, bottling machines, etc., can solve the problems of container jamming, container damage, and difficult to avoid clean room air pollution, etc., to achieve improved cleanliness and pollution elimination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

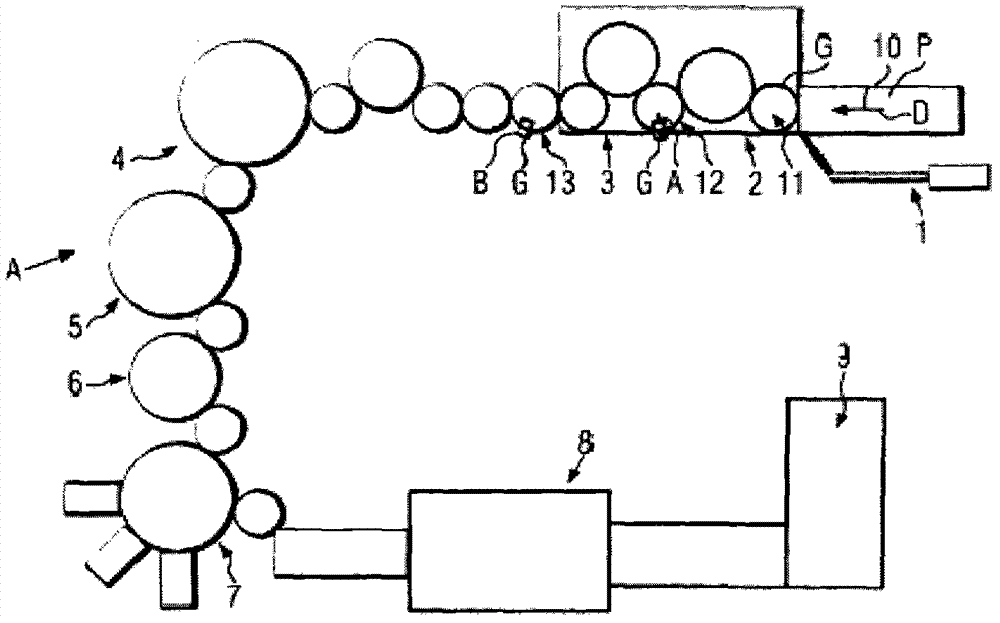

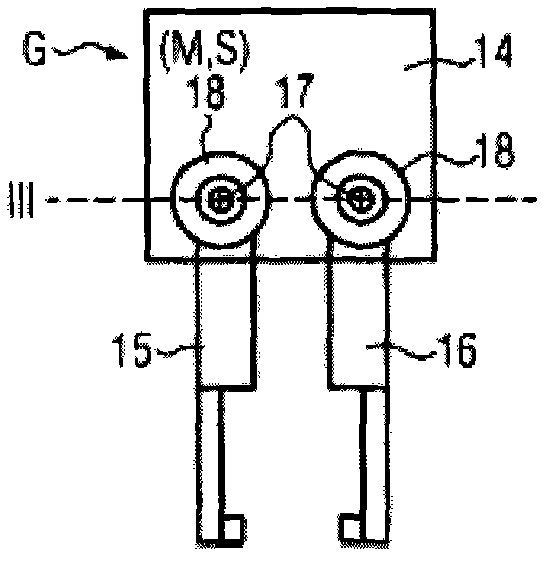

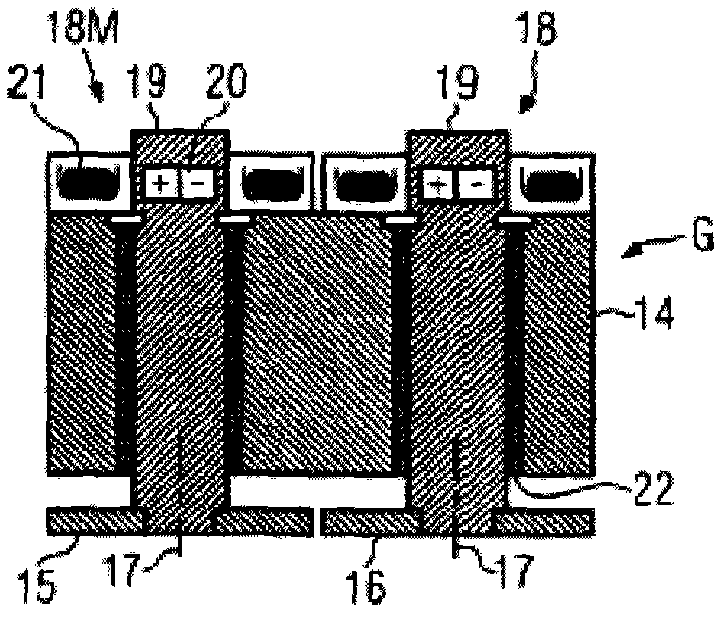

[0083] figure 1 The container treatment plant A shown in as a non-limiting example comprises, as part of the heating module 1, a transfer section 10 for the preforms P, in which the preforms at, for example, the holding mandrels D or the inner grippers are held. The preforms P are transferred, for example, to a further transfer section 11 defined by a transfer star wheel in an intermediate module 2 in which (optionally) a selective heat treatment of the preforms P is carried out (cf. Figure 29 , 30 ). In this process, the preform is brought into contact with temperature-controlled contact elements acting as clamping jaws in order to impose a temperature profile that varies, for example, in the circumferential direction. This is followed by the blow molding module 3 as another container handling machine, in which the transfer star wheel 12 is moved by the transfer arm A and the gripper G in the state of pitch distortion compensation. The temperature-controlled preform is tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com