Method for producing building gesso by using semi-hydrated phosphogypsum and dihydrate phosphogypsum

A technology of phosphogypsum dihydrate and building gypsum powder, which is applied in the field of building gypsum production, which can solve the problems of irregular shape, low solubility, and short construction operation time, and achieve the effect of fast initial setting time and high solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

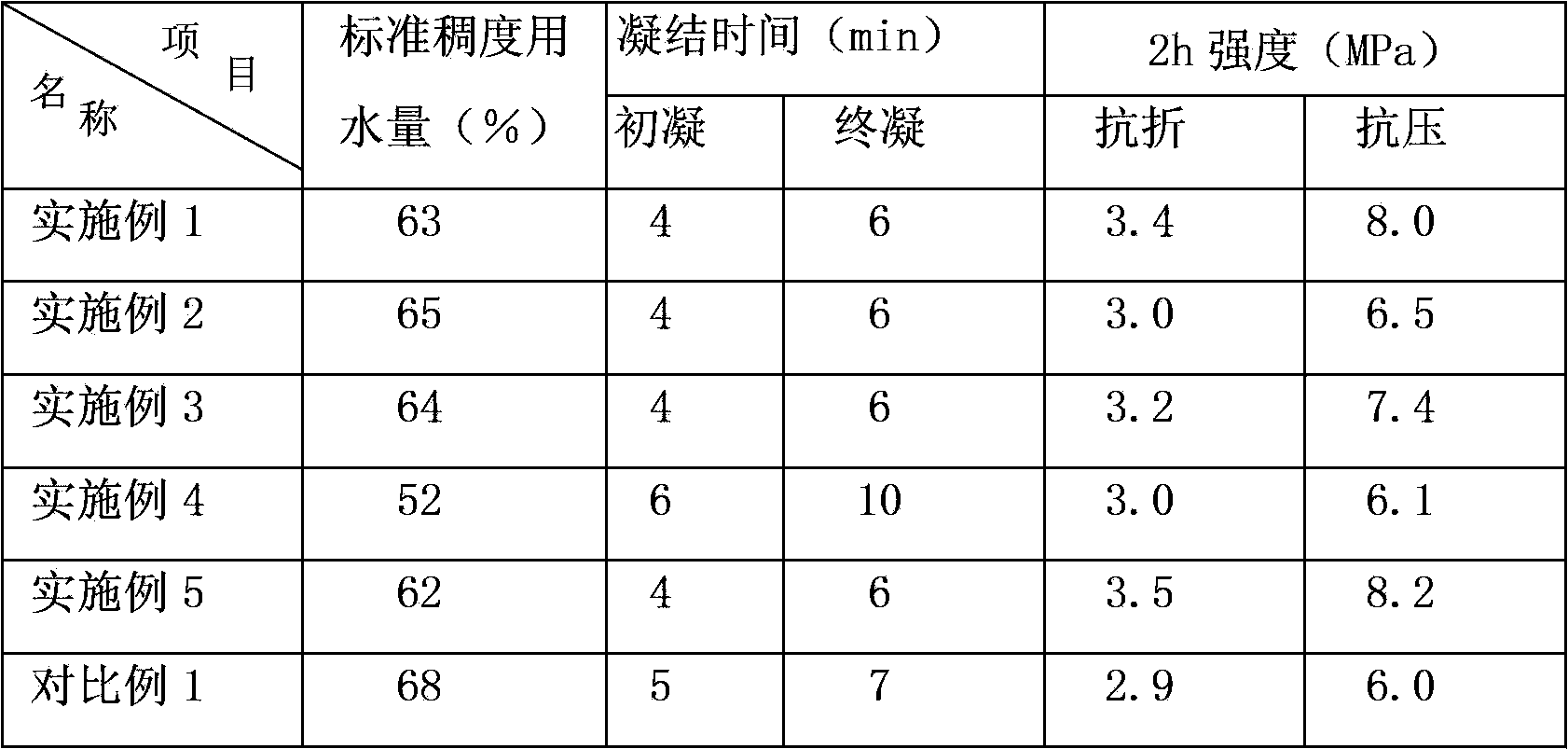

Examples

Embodiment 1

[0025] Prepare 2kg of raw materials with phosphogypsum hemihydrate and phosphogypsum dihydrate at a ratio of 20:80, put the raw materials into a wok for frying, take out the material when the temperature reaches 200°C, and ball mill the material to a square hole sieve with a particle size of 0.2mm after the material is cooled. Sieve residue ≤ 10%, aging for 3 days to obtain building gypsum powder.

Embodiment 2

[0027] Mix hemihydrate phosphogypsum and dihydrate phosphogypsum with 2kg of raw materials in a ratio of 5:95, put the raw materials into a wok for frying, take out the material when the temperature reaches 160°C, and ball mill the material until the particle size is 0.2mm square hole after cooling Sieve residue ≤ 10%, aging for 3 days to prepare building gypsum powder.

Embodiment 3

[0029] Mix hemihydrate phosphogypsum and dihydrate phosphogypsum with 2kg of raw materials in a ratio of 10:90, put the raw materials into a frying pan for frying, take out the material when the temperature reaches 180°C, and ball mill the material until the particle size is 0.2mm square hole after cooling Sieve residue ≤ 10%, aging for 3 days to prepare building gypsum powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com