Burden surface profile control method of blast furnace burden distribution and control system

A technology of control method and control system, applied in the field of material surface shape control method and control system of blast furnace material distribution, to achieve the effects of accurate detection, optimization of material distribution process, and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

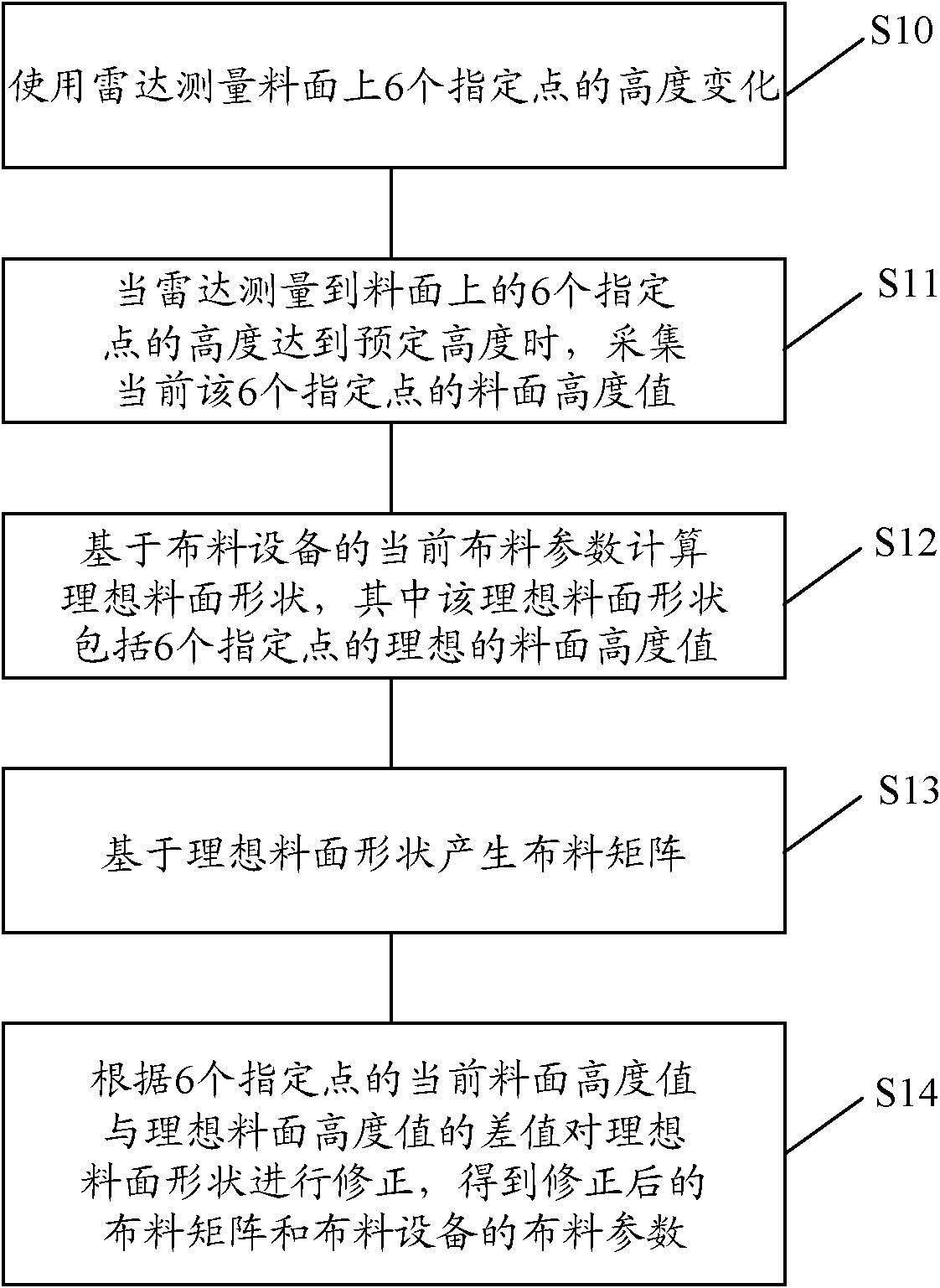

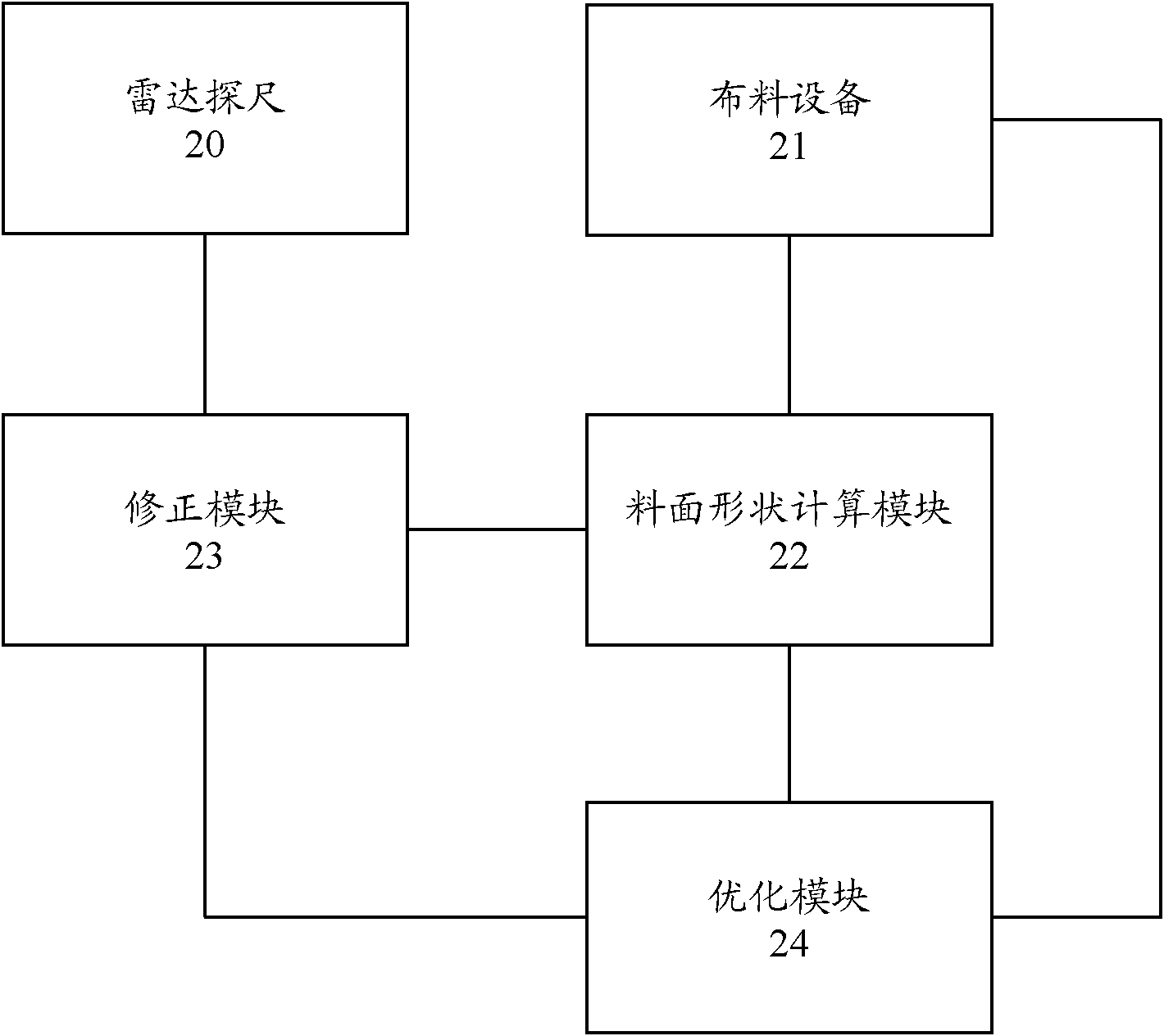

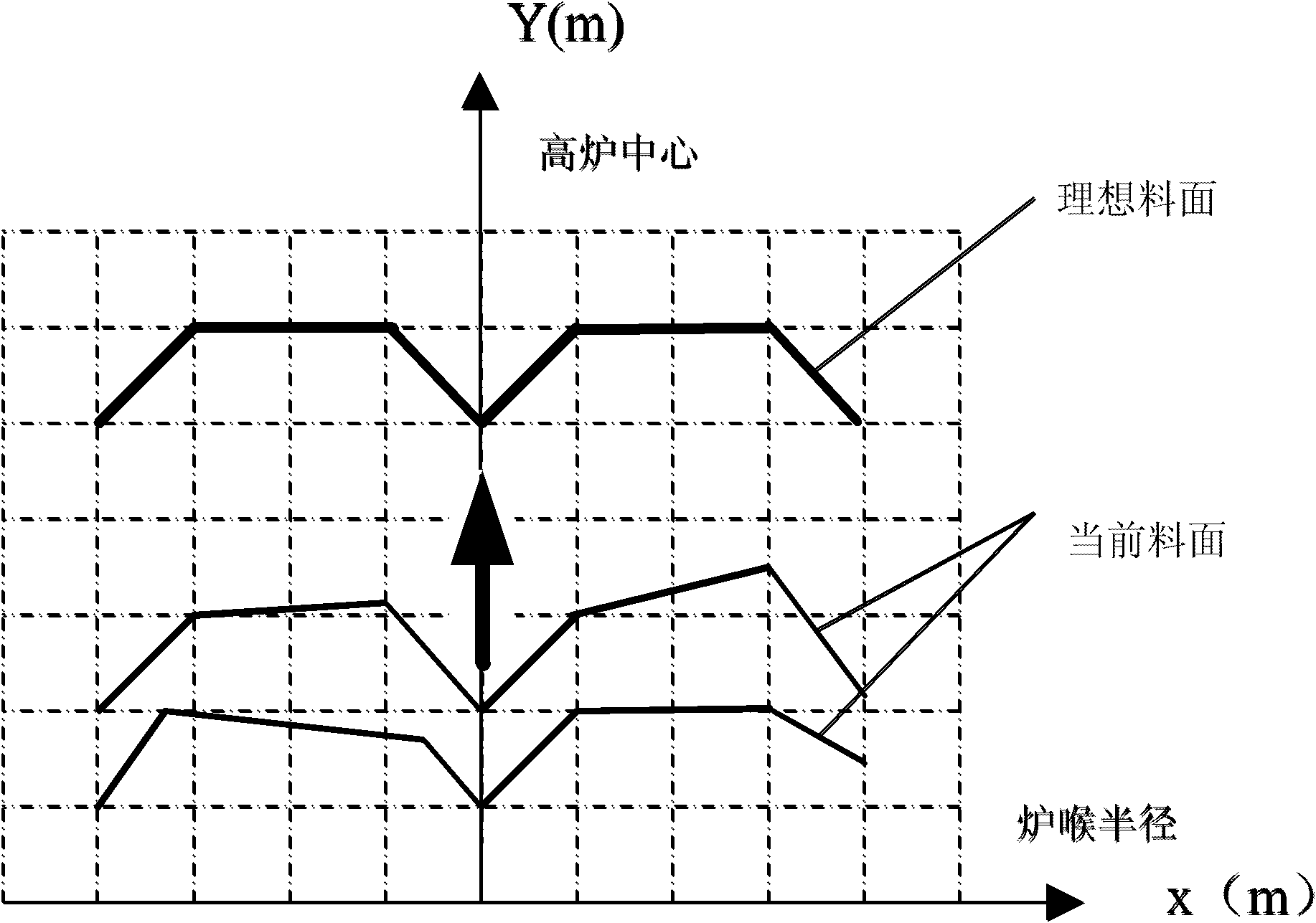

Method used

Image

Examples

Embodiment Construction

[0020] In the traditional method of controlling the material surface shape of the blast furnace material distribution, the mechanical probe material distribution control is mainly used: mainly based on a mechanical probe, the mechanical probe follows the material surface in a contact manner. As the smelting progresses, the material surface After the material surface drops to a set height, the mechanical probe is raised to start feeding. After adding the batch of furnace materials that have been manually set in advance, the mechanical probe is continued to be lowered to start a new round of feeding process. The traditional method is to select the detection point data of the mechanical probe on the material surface as the basis when the material level of the blast furnace changes, and take corresponding control operations according to the data of the mechanical probe. This method takes a point value as the controlled object, and the method of controlling the material surface is v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com