Modularized subsection-hoisting garage door

A garage door and modular technology, which is applied in the field of household garage doors, can solve the problems of long door replacement cycle, difficult maintenance, high production cost, etc., and achieve the effect of ideal replaceability, good system fastening, and convenient follow-up maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

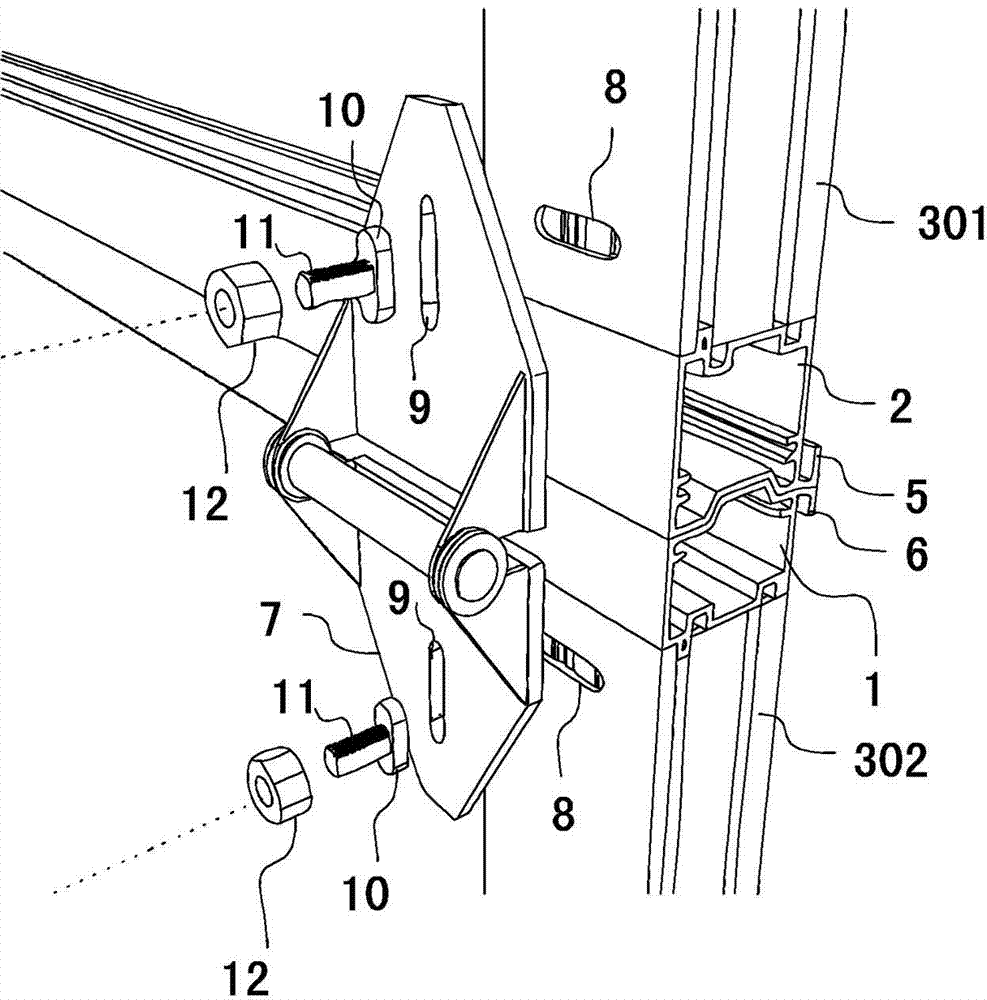

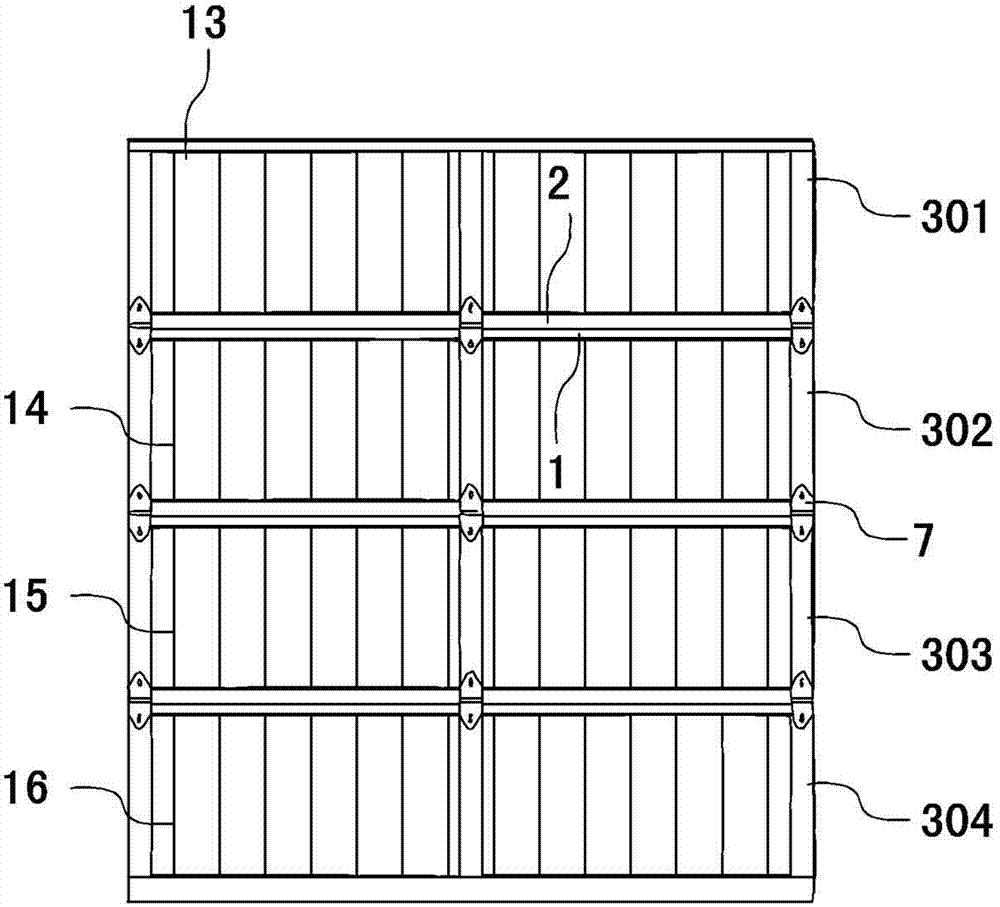

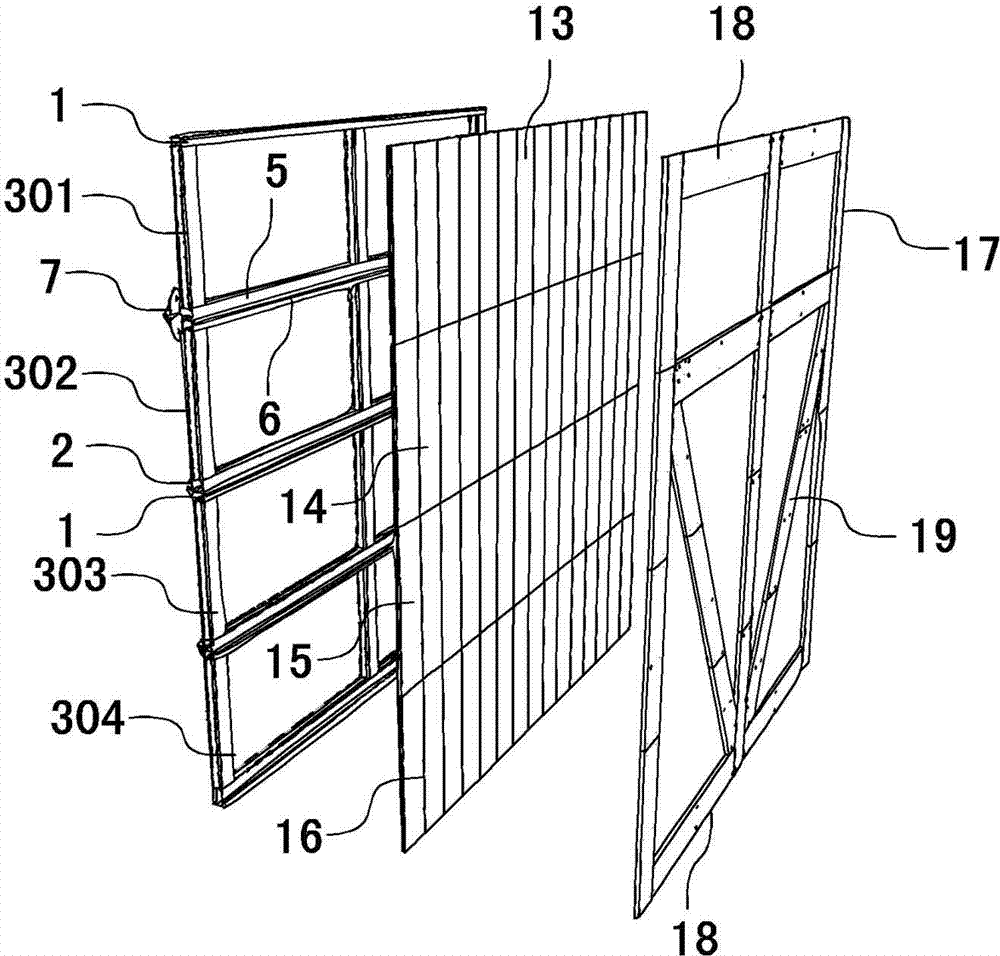

[0025] Such as figure 1 and figure 2 As shown, a modular section lifting garage door includes a first garage door frame unit 301 and a second garage door frame unit 302; the first garage door frame unit 301 is connected to the second garage door frame unit via a hinge 7 302 is fixedly connected; it is characterized in that the first door panel base unit 13 is fixedly embedded on the first garage door frame unit 301; the second door panel base unit 14 is fixedly embedded on the second garage door frame unit 302 .

[0026] see image 3 As shown, the present invention also includes a third garage door frame unit 303; the second garage door frame unit 302 is fixedly connected to the third garage door frame unit 303 via a hinge 7; the third garage door frame unit 303 is fixed The third door panel bottom panel unit 15 is embedded.

[0027] see image 3 As shown, the present invention also includes a fourth garage door frame unit 304; the third garage door frame unit 303 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com