Engine oil sprayer base connecting system

A fuel injector seat and connection system technology, applied in the direction of engine components, machines/engines, charging systems, etc., can solve the problems of inconvenient installation and maintenance, and achieve the effects of lower height, lower maintenance costs, and convenient after-sales service

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The principle and structure of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

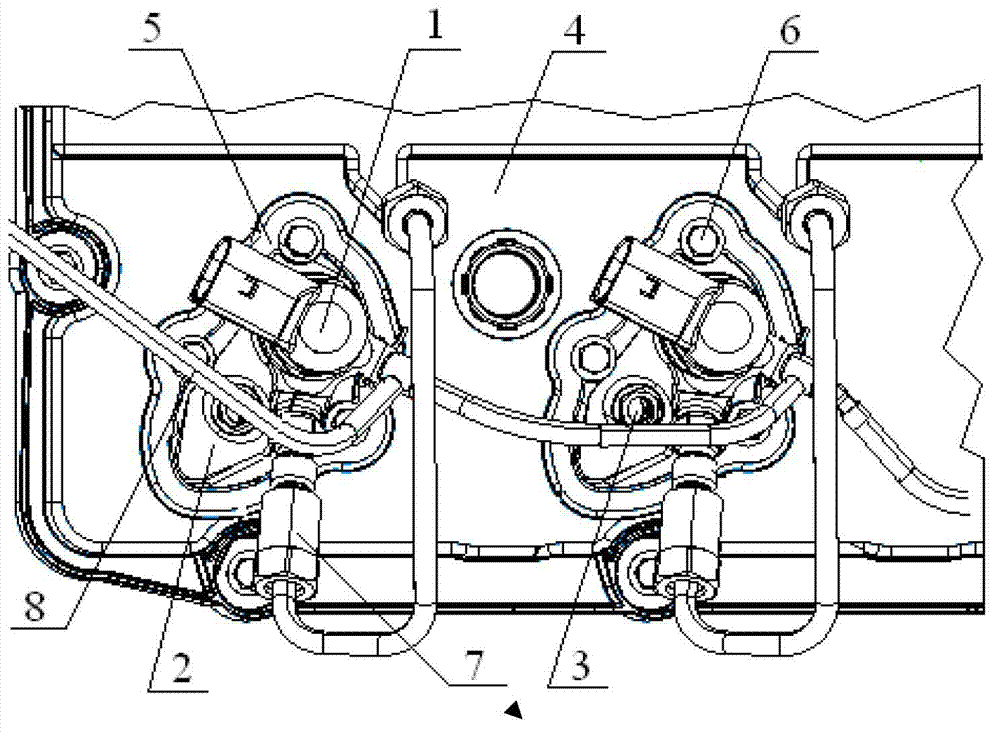

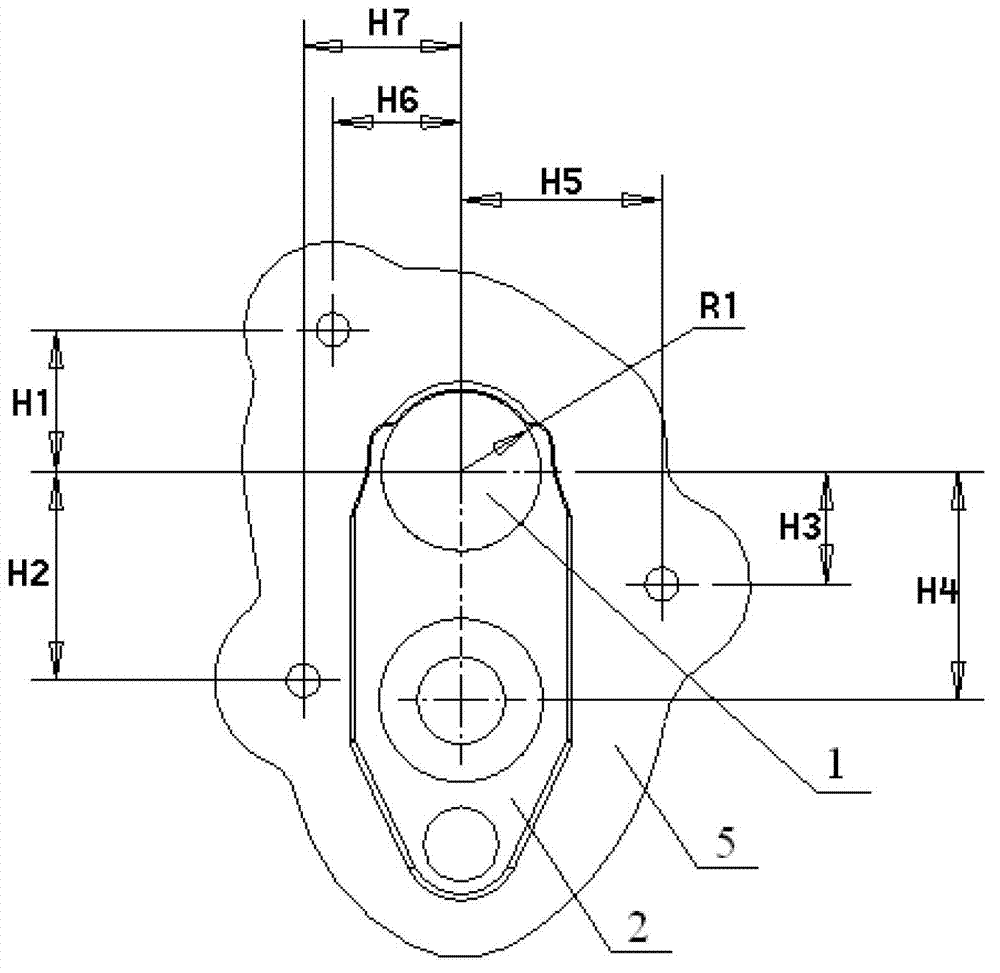

[0010] The connection system of the engine injector seat, its structure is: the injector 1 is sealed and fixed with the cylinder head through the injector pressure plate 2 on the injector seat 5 with a large bolt 3, and the injector seat 5 is also fixed through the large bolt 3 Bolt 3 is connected and fixed with the cylinder head. The cylinder head cover 4 has a cavity with the same shape as the fuel injector seat 5 according to the number of fuel injectors, and the fuel injector seat is connected and fixed with the cylinder head cover by three small bolts 6 . The high-pressure oil pipe 7 connected to the fuel injector, the small oil return pipe 8 and the electric control wiring harness are placed outside the cylinder head cover, and the seal rubber ring is used to seal between the fuel injector seat and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com