Microbubble generating device

A micro-bubble generation and water inflow technology, which is applied in transportation and packaging, mixers, mixing methods, etc., can solve the problems of reducing the use value of micro-bubbles, complex installation and fixing structures, and complex device structures, so as to reduce design difficulty and structure Simple, High-Precision Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

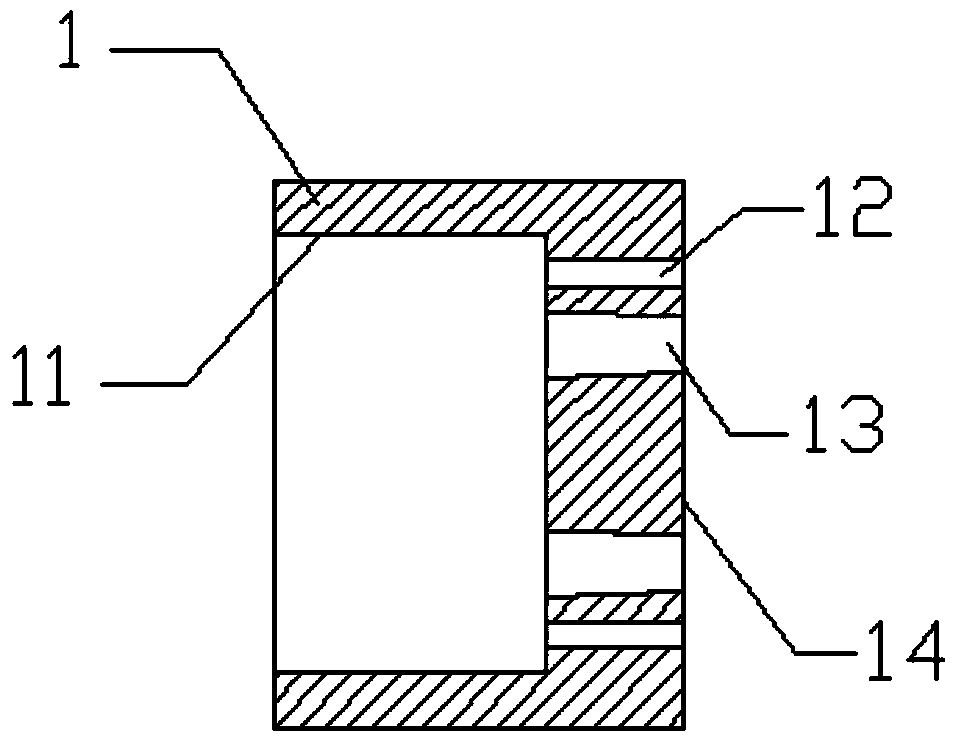

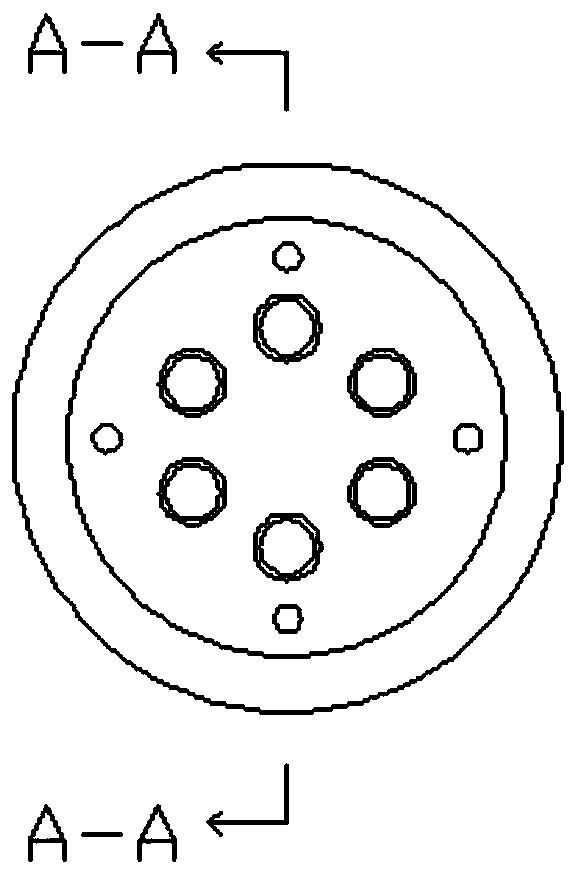

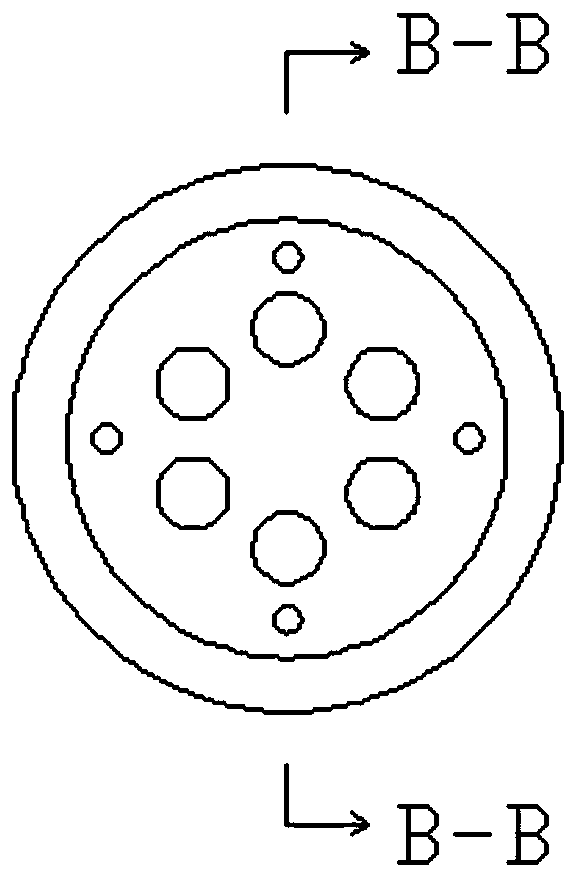

[0034] see Figure 1-9 , a micro-bubble generating device, comprising a water inlet part 1 and a water outlet part 2; the water inlet part 1 is in the shape of a cylinder, one end is an interface connected to a water supply pipeline, and the other end is along the circumference within the radial range of the interface. A group of first liquid passages 13 with decreasing axial inner diameters are provided in the direction, and a group of through holes 12 are arranged on the radially outer side of the first liquid passages 13; The end is a water outlet, and the front end is provided with a group of second liquid passages 22 corresponding to the first liquid passage 13 along the circumferential direction within the radial range of the water outlet. The inner diameter is larger than the inner diameter of the end of the first liquid channel 13; at least one layer of screen 3 is arranged in the water outlet; when the water inlet part 1 and the water outlet part 2 are docked, the gap...

Embodiment 2

[0046] The water outlet hole on the water outlet part 2 is not a threaded hole, but a through hole, and the blocking piece 4 is fixed with the through hole by means of interference fit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com