Diffuser and centrifugal fan equipped with same

A technology of centrifugal fan and diffuser, which is applied to components of pumping devices for elastic fluids, machines/engines, non-variable pumps, etc., and can solve the problem of insufficient diffusion of diffusers and low working efficiency of centrifugal fans and other problems, to achieve the effect of sufficient pressure expansion, hindering backflow, and increasing air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

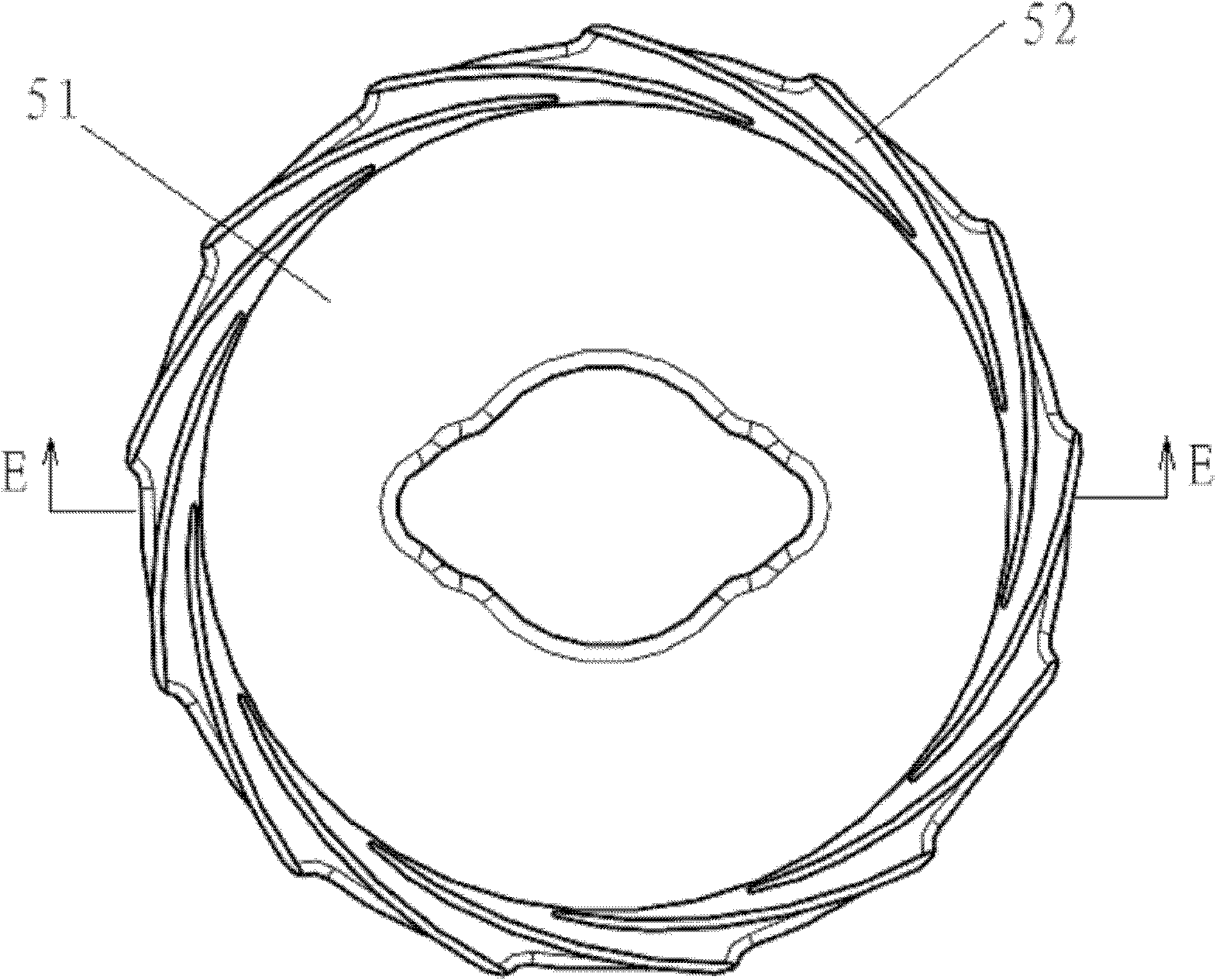

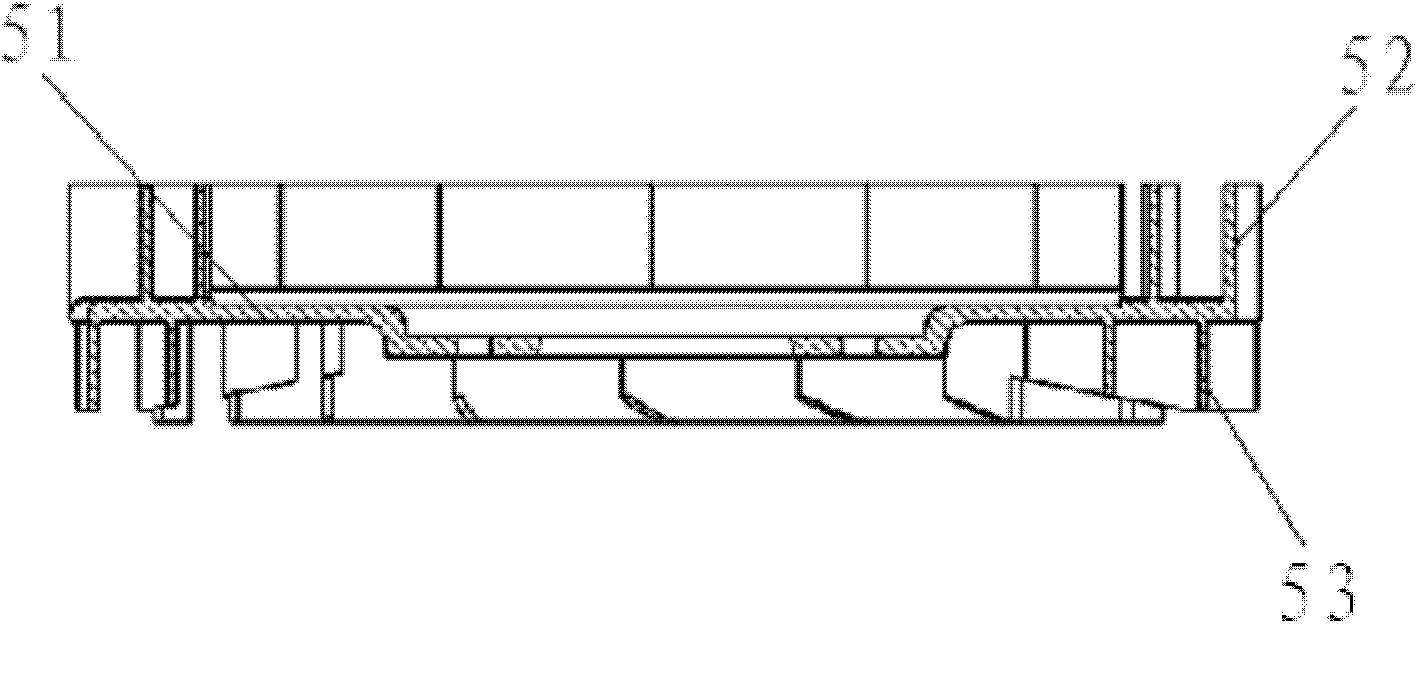

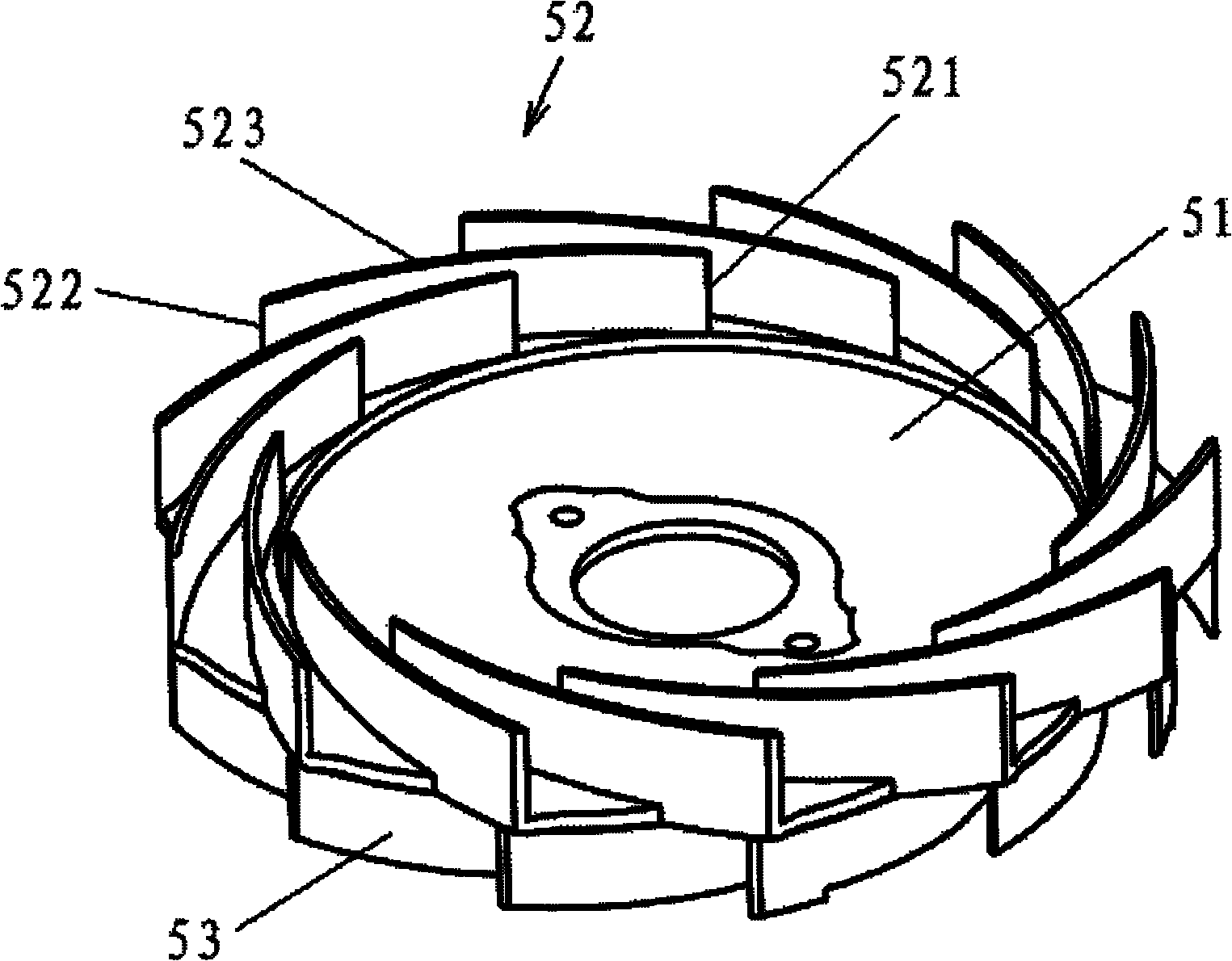

[0049] refer to Figure 3 to Figure 10 . in, image 3 It is a three-dimensional structural schematic diagram of the diffuser in the centrifugal fan of the present invention; Figure 4 is the top view structural diagram of the diffuser; Figure 5 express Figure 4 The F-F section view. Image 6 , Figure 7 Represent the structure of the first embodiment of the centrifugal fan of the present invention; Figure 8 , Figure 9 and Figure 10 The structure of the impeller in the first embodiment of the centrifugal fan of the present invention is shown.

[0050] The first embodiment of the centrifugal fan of the present invention includes a motor 2 installed in a motor casing 1, an impeller 3, a casing 4 and a diffuser. in

[0051] The impeller 3 includes an upper cover plate 31 , a lower cover plate 32 and several blades 33 . The upper cover plate 31 of the impeller 3 has a central through hole. Several blades 33 of the impeller 3 are spaced from each other and evenly ar...

Embodiment 2

[0056] refer to Figure 11 , Figure 12 . Figure 11 A schematic cross-sectional structure representation of the second embodiment of the centrifugal fan of the present invention; Figure 12 It shows the three-dimensional structure diagram of the casing in the second embodiment of the centrifugal fan of the present invention.

[0057] The case 4 has an upper cover portion 41 and a cylindrical portion 42 integral with the upper cover portion 41 . A plurality of rectangular openings 44 are uniformly arranged on the cylindrical portion 42 along the circumferential direction, and an air inlet 43 is provided in the center of the upper cover portion 41 of the casing 4 . On the upper cover plate 31 of the impeller 3, along the circumference of the air inlet 43, an air inlet baffle ring 45 integrally formed with the upper cover plate 31 is provided to ensure that the air entering by the air inlet 43 of the casing 4 can pass through the impeller 3 The central through hole of the up...

Embodiment 3

[0060] see Figure 13 . Figure 13 It shows the schematic cross-sectional structure diagram of the third embodiment of the centrifugal fan of the present invention.

[0061] The third embodiment of the centrifugal fan of the present invention is a combination of the first embodiment and the second embodiment of the centrifugal fan, that is, the first baffle ring 6 is set on the upper cover plate 31 of the impeller 3, and the casing 4 The second baffle ring 7 is arranged on the top, and the first baffle ring 6 and the second baffle ring 7 are arranged in a staggered manner to play a double function of preventing backflow. The other structures of the third embodiment of the centrifugal fan, such as the motor housing, motor, impeller and diffuser, are basically the same as those of the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com