Electric heater for high temperature air

An electric heater and high-temperature air technology, applied in the field of high-temperature air electric heaters and air electric heaters, can solve the problems of low maximum temperature, waste of energy, large heat loss, etc., and achieve high heating and cooling rates and large gas flow , The effect of small flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

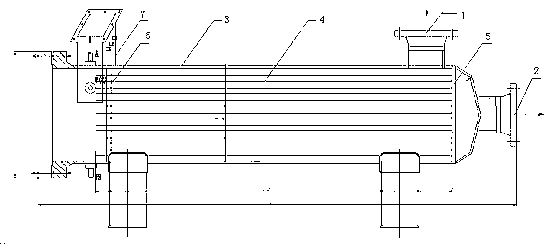

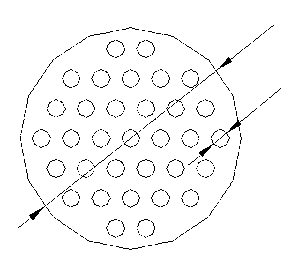

[0020] refer to figure 1 , one A high-temperature air electric heater is composed of a hollow electric heating tube 4, a sealed pressure vessel 3 with a cold air inlet 1 and a hot air outlet 2, an insulating fixing member 5 at the front end, and an insulating sealing fixing member 6 at the tail end. The end is sealed, and the front end is provided with a hot air outlet 2, and a cold air inlet 1 is provided on the wall of the pressure vessel 3 near the front end. part 5, a number of holes are arranged on the front end insulating fixing part 5 to fix the electric heating tube 4, and a tail end insulating sealing fixing part 6 is arranged near the tail end inside the sealed pressure vessel 3, and the tail end insulating sealing fixing part 6 is provided with A number of holes are used to fix the electric heating tube 4, and a number of hollow electric heating tubes 4 are fixed inside the sealed pressure vessel 3 through the front insulating fixing part 5 and the tail end insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com