Method for testing deicing effect of rubber grain bituminous pavement

A technology for asphalt pavement and effect testing, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of poor simulation, small test area, relatively large influence, etc., and achieve a small measurement workload, simple test instruments, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

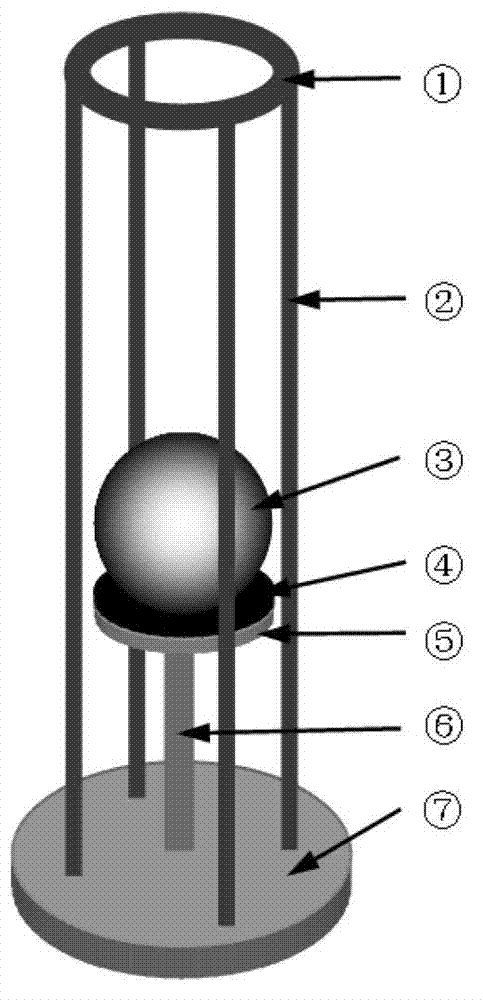

[0017] The invention provides a device for testing the deicing effect of rubber particle asphalt pavement. see figure 1 , the test device includes a circular steel bar (1), a plurality of steel bars (2), steel balls (3), rubber pads (4), a first steel plate (5), a connecting rod (6), a second steel plate (7) , the plurality of reinforcement rods (2) are evenly distributed along the circumferential direction of the annular reinforcement (1), one end of the plurality of reinforcement rods (2) is fixedly connected to the annular reinforcement (1), and the other end is fixedly connected to the On the upper surface of the second steel plate (7), and perpendicular to the second steel plate, the first steel plate (5) is parallel and coaxial with the second steel plate (7), the first steel plate (5) is circular, and the second The steel plate (7) is also circular, one end of the connecting rod (6) is fixed at the center of the upper surface of the second steel plate (7), the other en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com