Blood gas analyzer and using method thereof

A blood gas analyzer and pump body technology, applied in the field of blood gas analyzers, can solve the problems of fragile solenoid valves, cumbersome use process, and large gas cylinders, so as to reduce the probability of failure, reduce the probability of failure, and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

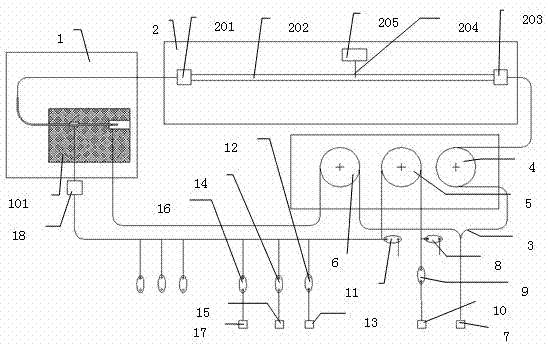

[0025] Example 1, see figure 1 , a blood gas analyzer, comprising: a needle valve 101 placed in a sampling rack 1, a sample case 2 connected to the needle valve 101, a first pump body 4 connected to the sample case 2, a first pump connected to the The waste liquid bag 7 of the body 4, the liquid detector 18 connecting the needle valve 101 and the second pump body 5, the fourth reagent bag 10 connected to the second pump body 5 through the second electromagnetic valve 9, and the fourth reagent bag 10 connected to the second pump body 5. The third solenoid valve 11 of the liquid detector 18, the first solenoid valve 8 connected to the second pump body 5, the first reagent bag 17 connected to the liquid detector 18 through the sixth solenoid valve 16, and the first reagent bag 17 connected to the liquid detector 18 through the fifth The solenoid valve 14 is connected to the second reagent bag 15 of the liquid detector 18, the third reagent bag 13 connected to the liquid detector ...

Embodiment 2

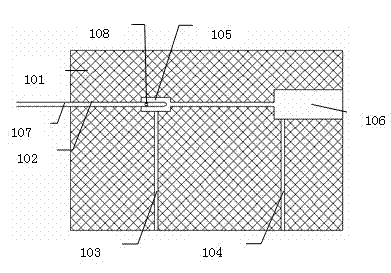

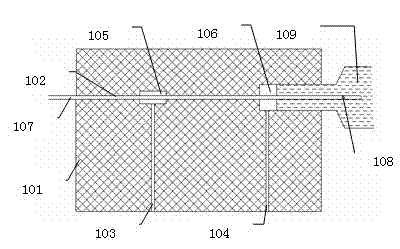

[0027] Example 2, see figure 2 , there is a main passage 102 in the needle valve 101, a first sampling port 105 and a second sampling port 106 are arranged on the main passage 102, the first sampling port 105 is connected to the first passage 103, and the second sampling port 106 is connected to the second sampling port 106. Channel 104; the first reagent, the second reagent, the protein-removing solution and the cleaning solution enter the main channel 102 in the needle valve 101 through the first channel 103, and enter the subsequent flow pipe 3 at the first sampling port 105 of the main channel 102; When cleaning the flow path, the cleaning liquid entering the main channel 102 is divided into two parts, one part enters the flow path pipe 3 from the first sampling port 105, cleans the sample box 2 and the subsequent flow path, and finally enters the waste liquid bag 7, and the other part enters the flow path pipe 3 from the first sampling port 105, and finally enters the was...

Embodiment 3

[0028] Example 3, see figure 1 with figure 2 , the first channel 103 is connected to the liquid detector 18, so that the first reagent, the second reagent, the deproteinized solution and the cleaning solution enter the main channel 102 in the needle valve 101 through the flow pipe 3, and the second channel 104 passes through the flow path The tube 3 is connected to the third pump body 6, so that the cleaning liquid can pass through the third pump body 6 smoothly and enter the waste liquid bag 7, so as to facilitate the cleaning of the flow path.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com