Passive direct evaporation type cooling system for double-layer concrete containment

A double-layer concrete and evaporative cooling technology, which is applied in nuclear power generation, cooling devices, reactors, etc., can solve problems such as system boiling, and achieve the effect of easy engineering implementation and internal boiling of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

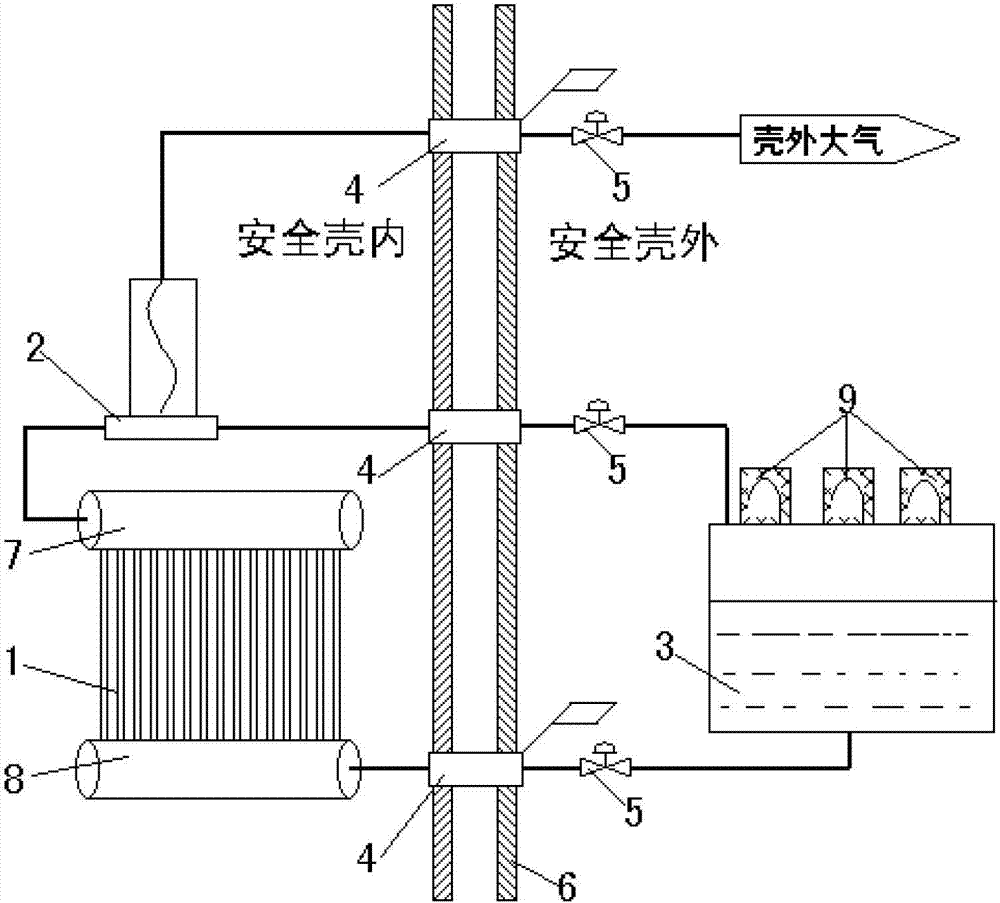

Embodiment 1

[0021] Such as figure 1 As shown, the passive direct evaporative cooling system for double-layer concrete containment includes a heat exchanger 1 inside the containment 6, and a heat exchanger 1 connected to the heat exchanger 1 through the The cooling water tank 3 outside the shell 6 and the heat exchanger 1 are provided with headers 7 and 8 for connecting a single light pipe. The heat exchanger 1 is connected to the steam-water separator 2, and the high-temperature steam generated by the heat exchanger 1 passes through the steam-water separator 2 and is directly discharged into the atmosphere outside the containment vessel. The steam-water separator 2 of this embodiment is located inside the containment vessel 6, and the steam-water separator 2 is connected to the ascending pipe passing through the containment penetrating piece 4 and communicating with the atmosphere, and is connected to the outside of the containment vessel through the descending pipe passing through the co...

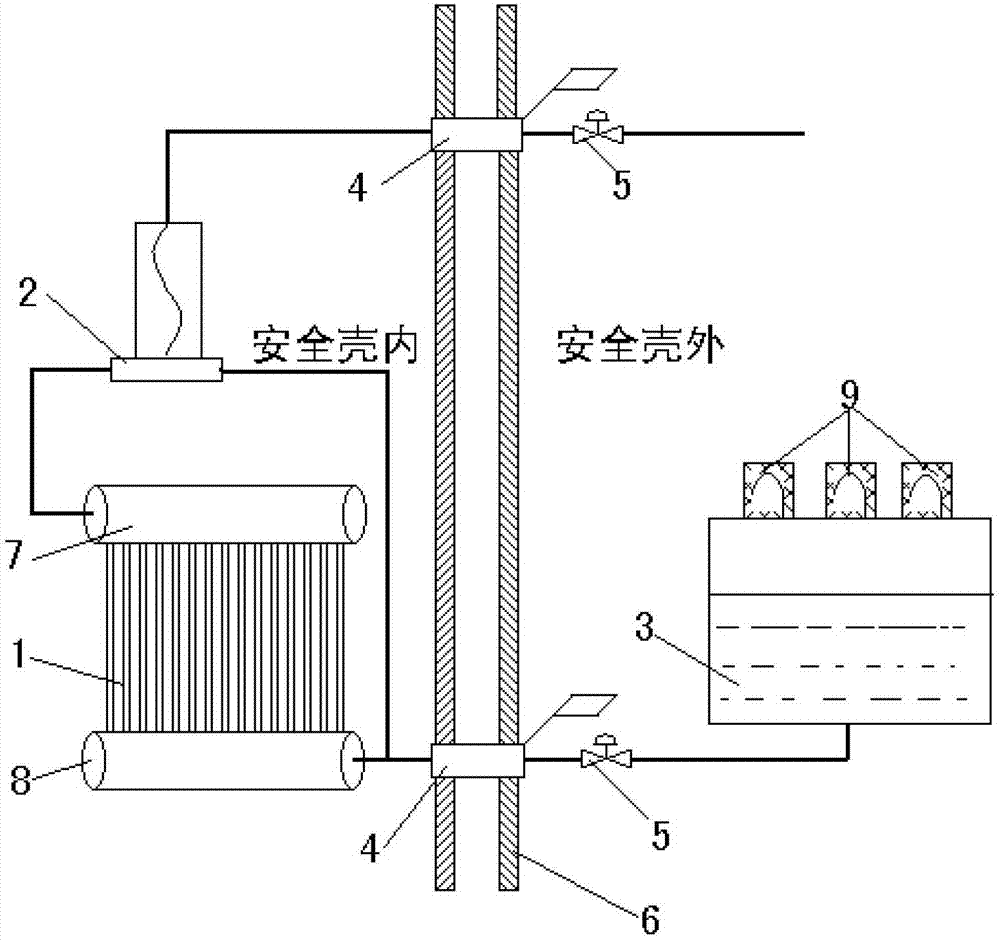

Embodiment 2

[0024] Such as figure 2 As shown, the passive direct evaporative cooling system for double-layer concrete containment includes a heat exchanger 1 inside the containment 6, and a heat exchanger 1 connected to the heat exchanger 1 through the The cooling water tank 3 outside the shell 6 and the heat exchanger 1 are provided with headers 7 and 8 for connecting a single light pipe. The heat exchanger 1 is connected to the steam-water separator 2, and the high-temperature steam generated by the heat exchanger 1 passes through the steam-water separator 2 and is directly discharged into the atmosphere outside the containment vessel. The steam-water separator 2 of this embodiment is located inside the containment vessel 6, and the steam-water separator 2 is connected to an ascending pipeline that passes through the containment penetrating piece and communicates with the atmosphere, and is connected to the heat exchanger 1 through a descending pipeline; the steam-water separator 2 Th...

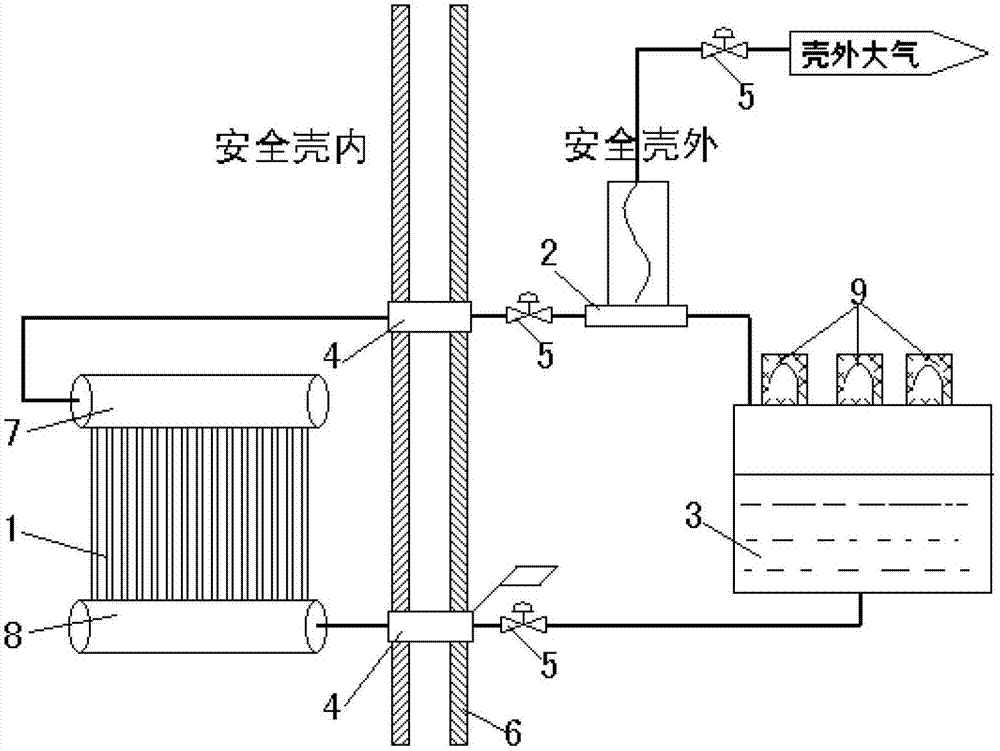

Embodiment 3

[0027] Such as image 3 As shown, the passive direct evaporative cooling system for double-layer concrete containment includes a heat exchanger 1 inside the containment 6, and a heat exchanger 1 connected to the heat exchanger 1 through the The cooling water tank 3 outside the shell 6 and the heat exchanger 1 are provided with headers 7 and 8 for connecting a single light pipe. The heat exchanger 1 is connected to the steam-water separator 2, and the high-temperature steam generated by the heat exchanger 1 passes through the steam-water separator 2 and is directly discharged into the atmosphere outside the containment vessel. The steam-water separator 2 of this embodiment is located outside the containment vessel 6, and the steam-water separator 2 is connected to an ascending pipeline connected to the atmosphere, and is connected to the cooling water tank 3 through a descending pipeline; The pipeline is discharged into the atmosphere, and the liquid water separated by the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com