Fuel cell metal separator and noble metal coating method therefor

一种金属隔板、燃料电池的技术,应用在燃料电池、燃料电池助剂、燃料电池的零部件等方向,能够解决金易剥离、无法长期良好使用、金属隔板耐用年数下降等问题,达到抑制剥离的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

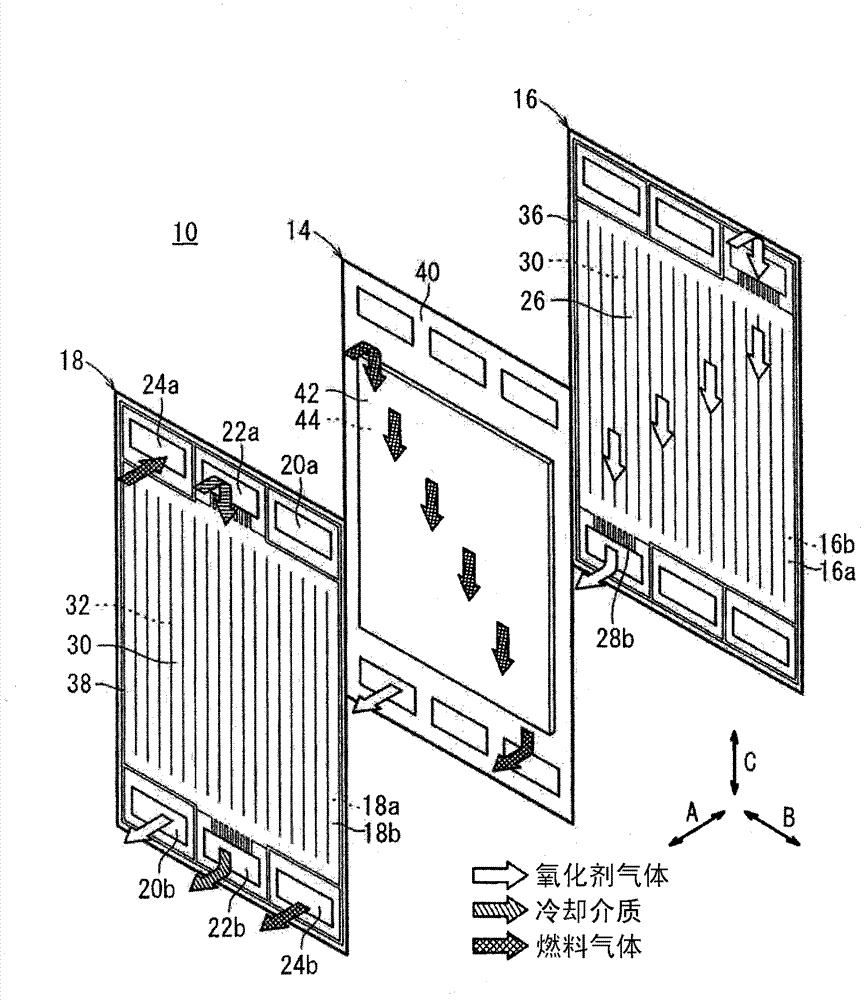

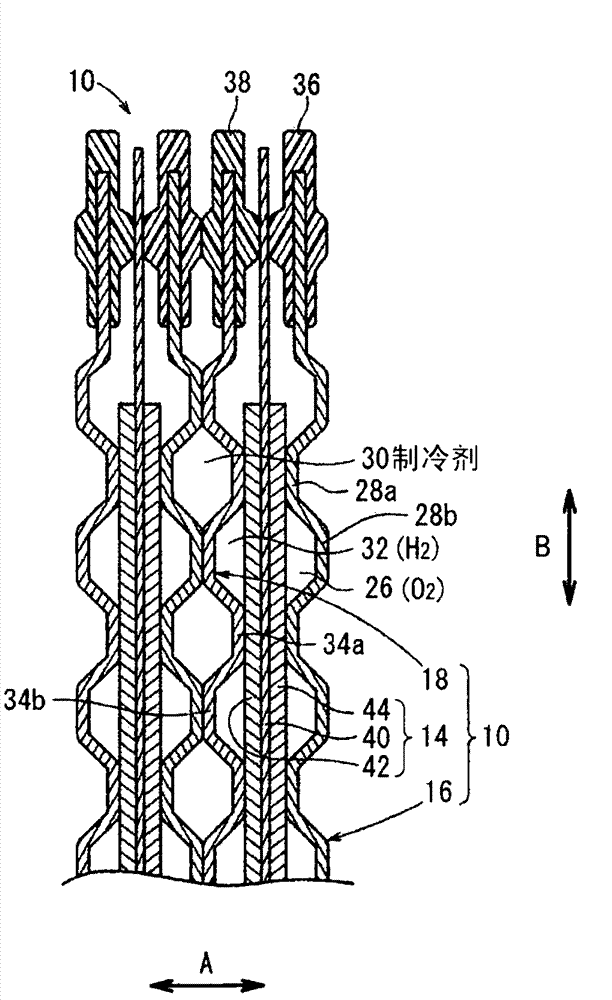

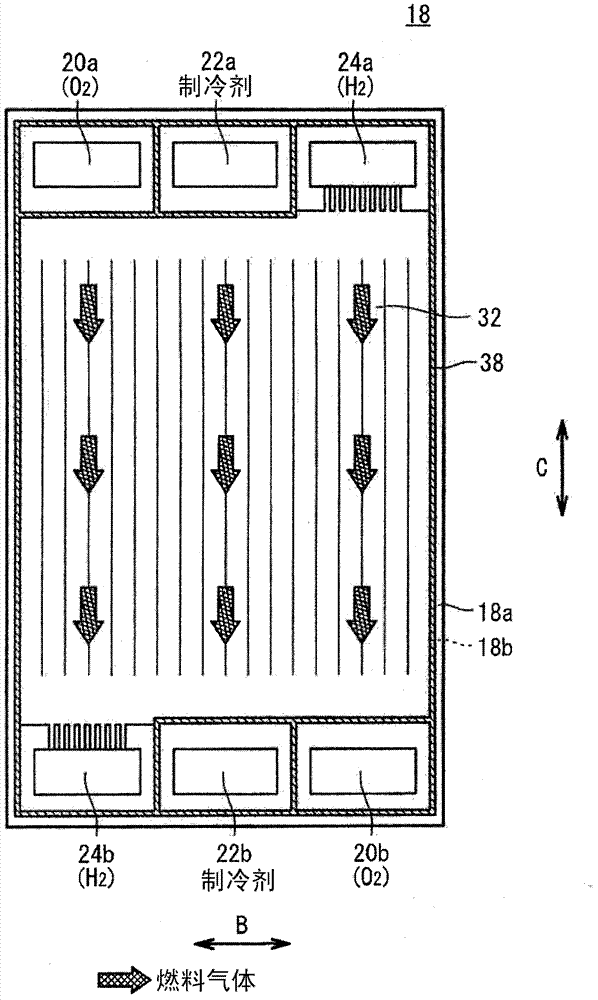

[0028] like figure 1 and figure 2 As shown, the electrolyte membrane electrode structure (electrolyte electrode structure) 14 of the fuel cell 10 is sandwiched between the first metal separator 16 and the second metal separator 18 according to the first embodiment of the present invention. The electrolyte membrane electrode structure 14 and the first metal separator 16 and the second metal separator 18 are laminated in the horizontal direction (arrow A direction) such that the electrode surfaces are vertical surfaces.

[0029] The first metal separator 16 and the second metal separator 18 have a vertically long shape extending in the direction of gravity. The first metal separator 16 and the second metal separator 18 are made of, for example, a steel plate, a stainless steel plate, an aluminum plate, or a plated steel plate, and have a rectangular shape in plan, and are formed by stamping a thin metal plate into a corrugated plate shape. It is the concave-convex shape of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| area ratio | aaaaa | aaaaa |

| area ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com