Elastomer assembly for shock absorption of heavy truck rear suspension

A technology of heavy-duty vehicles and elastic bodies, which is applied in the direction of suspension, elastic suspension, spring/shock absorber, etc. It can solve the problems of complex overall structure, inability to limit the separation movement of axle housing and frame, and increase in cost, and achieve assembly Simple maintenance, improved reliability and economy, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation manner.

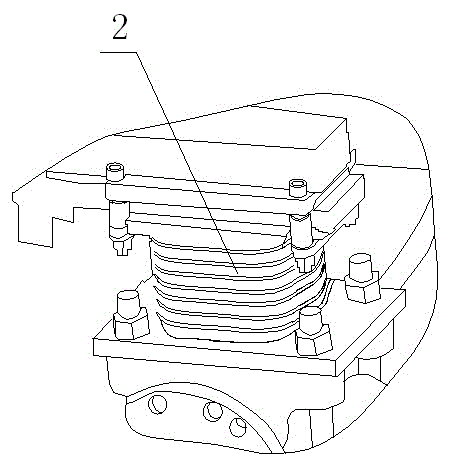

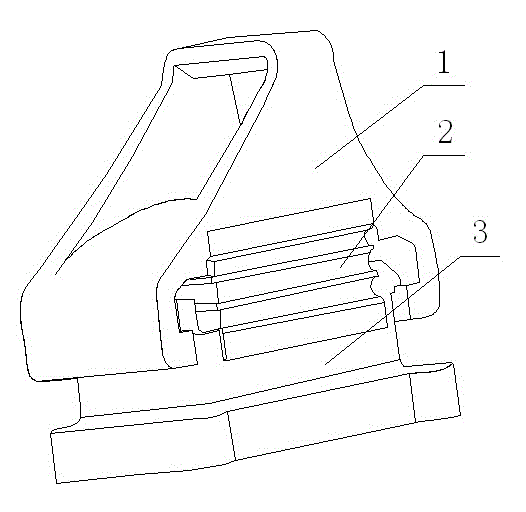

[0024] As shown in the accompanying drawing, a heavy-duty vehicle rear suspension shock-absorbing elastic body assembly includes a slide plate 1, an elastic body 2, and a lower plate 3. Clamping, the elastic body 2 is assembled in the space formed by the slide plate 1 and the lower plate 3 .

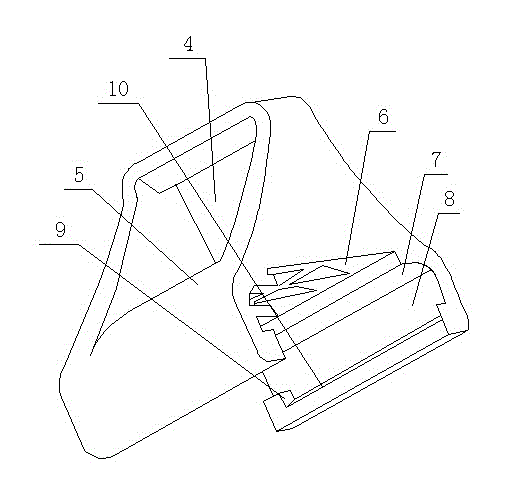

[0025] The elastic body 2 includes 3-5 layers of steel plates, and there is a polymer elastic layer between adjacent steel plates. The polymer elastic layer is vulcanized together with the steel plates through a vulcanization process. The outer flange 16 is in contact with the sides of the slide plate 1 and the lower plate 3 respectively and reliably clamps the contact surfaces.

[0026] The slide plate 1 includes an upper frame part and a lower frame part, the upper frame part has a longitudinal installation hole 4, the lower sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com