Mining pneumatic stepless speed change concrete agitating conveying vehicle

A technology for mixing and conveying vehicles and variable speed concrete, which is applied in the direction of concrete transportation, etc., and can solve the problem that the mining concrete mixing and conveying vehicles cannot perform stepless speed regulation, the mining concrete mixing and conveying vehicles have long working hours, and cannot meet the technical requirements of underground construction, etc. problems, to achieve the effect of meeting the demand for concrete, eliminating the need for motors and electric controls, and enriching the air source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

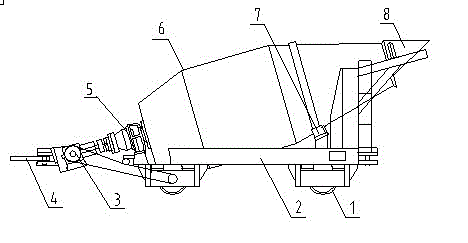

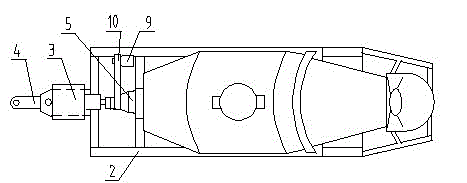

[0014] Example 1, in figure 1 and figure 2 Among them, the mine pneumatic stepless variable speed concrete mixer truck includes a walking mechanism 1, a frame 2, a clutch mechanism 3, a drawbar 4, a planetary reducer 5, a mixing drum 6, a radial support wheel 7, a hopper 8, Pneumatic motor 9 and belt transmission mechanism 10, the mixing drum is supported on the vehicle frame 2 by radial supporting wheels 7, one end of the mixing drum is connected with the planetary reducer 5, and the other end of the mixing drum is provided with a hopper 8, the vehicle A wind motor 9 is arranged on the frame, and the wind motor is connected with the planetary reducer 5 through a belt transmission mechanism 10 (the belt transmission mechanism includes a transmission belt and a transmission wheel). To prevent the concrete from solidifying when no anticoagulant is added during transportation, the planetary reducer can also be connected to the clutch mechanism 3, and the clutch mechanism is con...

Embodiment 2

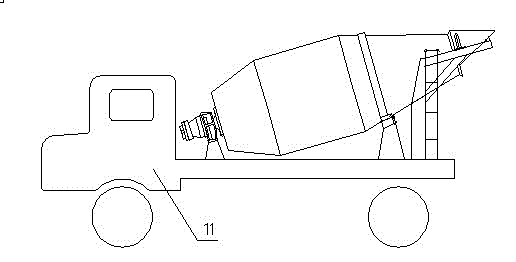

[0015] Example 2, in image 3 Among them, the mine pneumatic stepless variable speed concrete mixer truck includes a running mechanism 1, a frame 2, a wind motor 9, a belt transmission mechanism 10, a drawbar 4, a planetary reducer 5, a mixing drum 6, and a radial support wheel 7, hopper 8 and clutch mechanism 3, the mixing drum is supported on the vehicle frame by radial supporting wheels 7, one end of the mixing drum is connected with the planetary reducer 5, and the other end of the mixing drum is provided with a hopper 8, and the vehicle frame A wind motor 9 is arranged on the top, and the wind motor is connected with the planetary reducer 5 through a belt transmission mechanism 10 (the belt transmission mechanism includes a transmission belt and a transmission wheel). The concrete is solidified when no anticoagulant is added during transportation, and the planetary reducer can also be connected with the clutch mechanism 3, and the clutch mechanism is connected with the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com