Travelling frame

A technology of frame and road wheel, applied in axles, wheels, vehicle parts, etc., can solve the problems of high cost, complex structure of road wheel shock absorber system, difficult maintenance, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

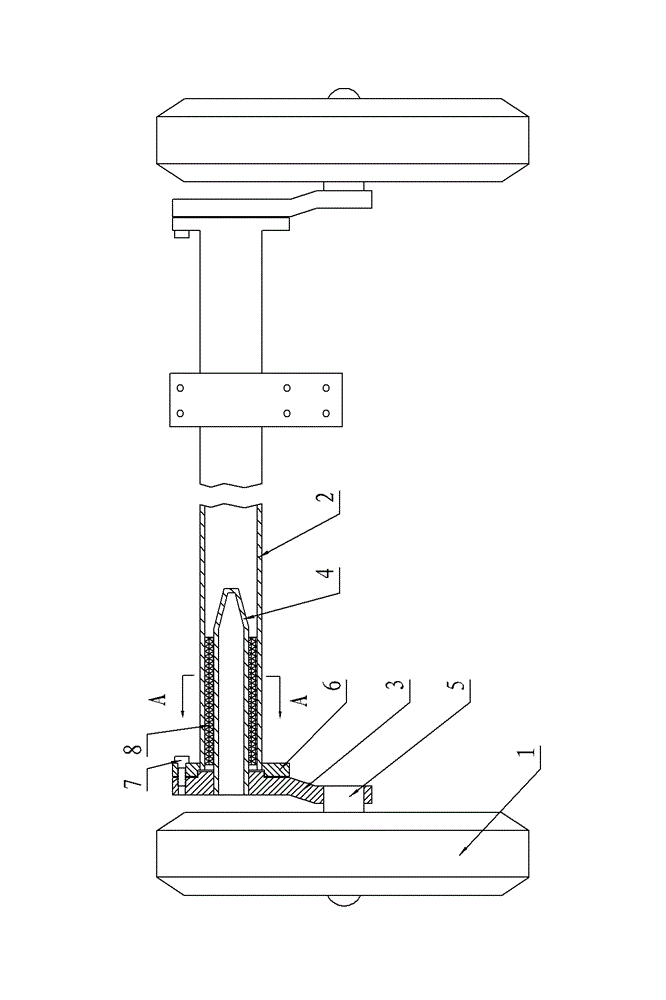

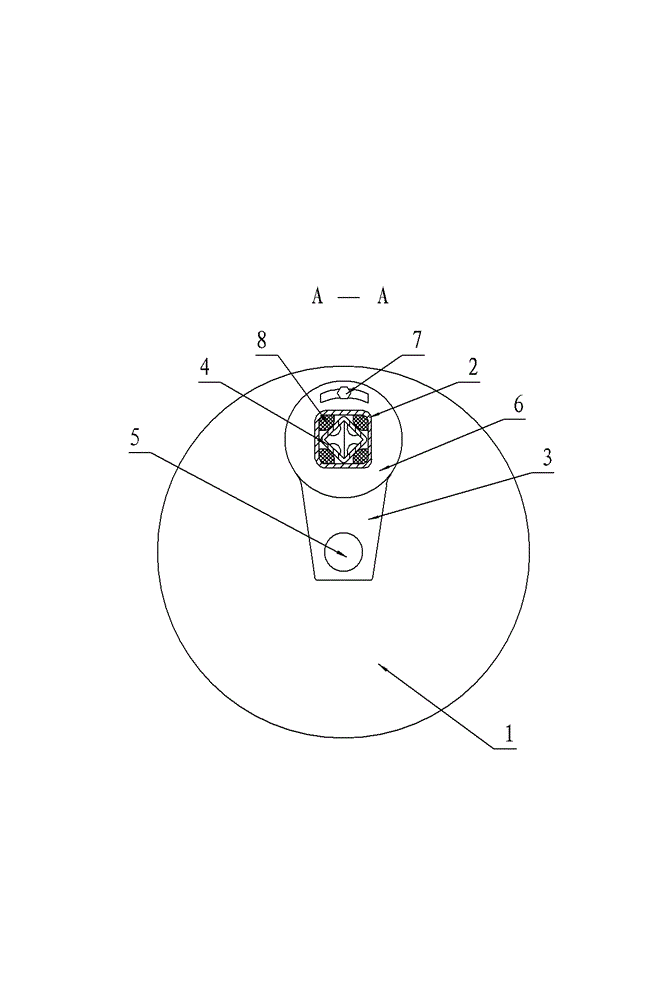

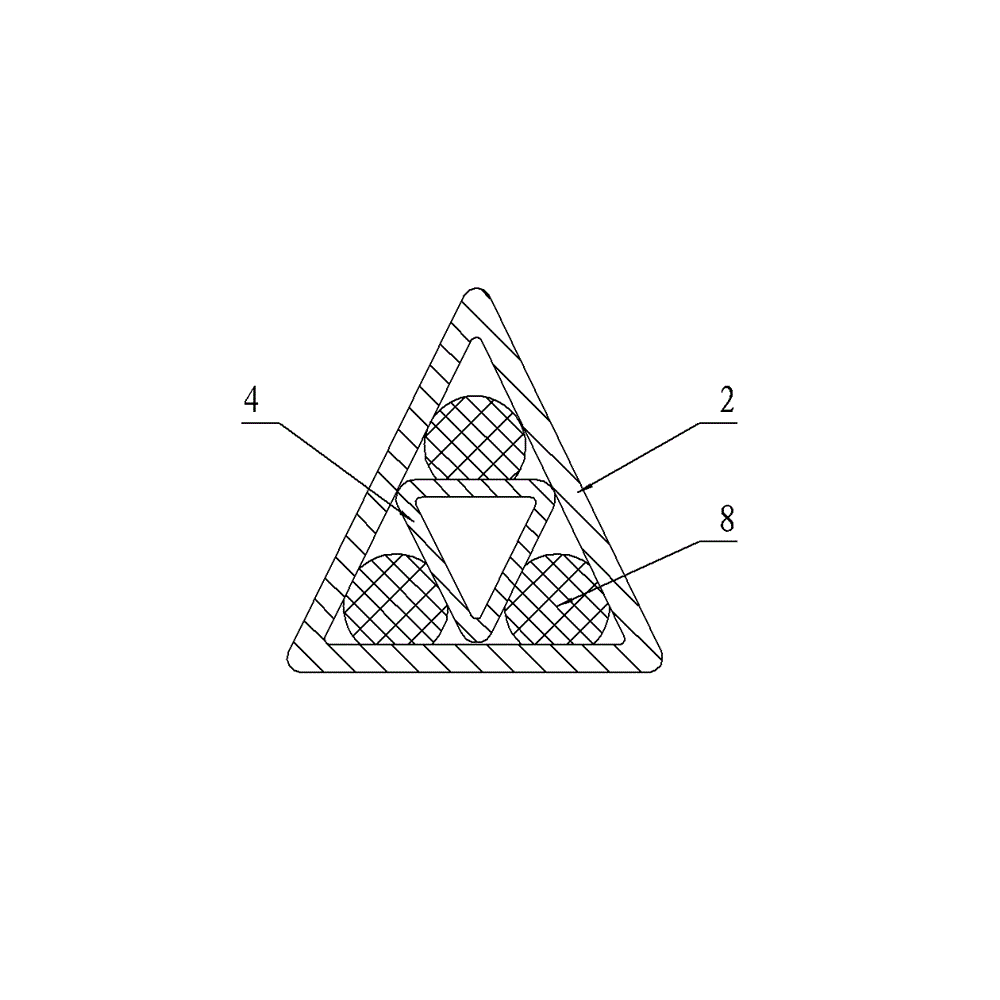

[0015] figure 1 with figure 2 The traveling vehicle frame shown includes a traveling wheel 1 and a vehicle beam 2 . The vehicle beam 2 is a square tube body, the wheel shaft 5 of the road wheel 1 is connected with one end of the swing arm 3, and the upper end of the swing arm 3 is fixedly connected with the vehicle beam 2 through the flange 6 connected with the end of the vehicle beam 2 with a screw 7, The screw 7 has the upper and lower dead points for controlling the swing of the wheel; the other end of the swing arm 3 is connected with the shaft core 4 in the vehicle beam 2, and the shaft core 4 is also a square tube, and the four corners of the shaft core 4 square tube are placed At the midpoint of the four sides of the inner wall of the square tube of the vehicle beam 2; the shaft core 4 is rotatable relative to the tube wall of the vehicle beam 2; four e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com